PCB SMT Stencils Market of Trends and Applications

By:PCBBUY 09/29/2025 16:37

In today’s electronics manufacturing industry, precision is everything. From smartphones to automotive control systems, every modern device depends on flawless soldering during PCB assembly. This is where SMT stencils come into play. As the pcb smt stencils market continues to grow worldwide, manufacturers are looking for partners that can deliver both accuracy and speed.

At PCBBUY, we combine advanced stencil production with PCB fabrication and assembly services, offering customers a reliable, one-stop solution to meet their production needs.

What Are PCB SMT Stencils?

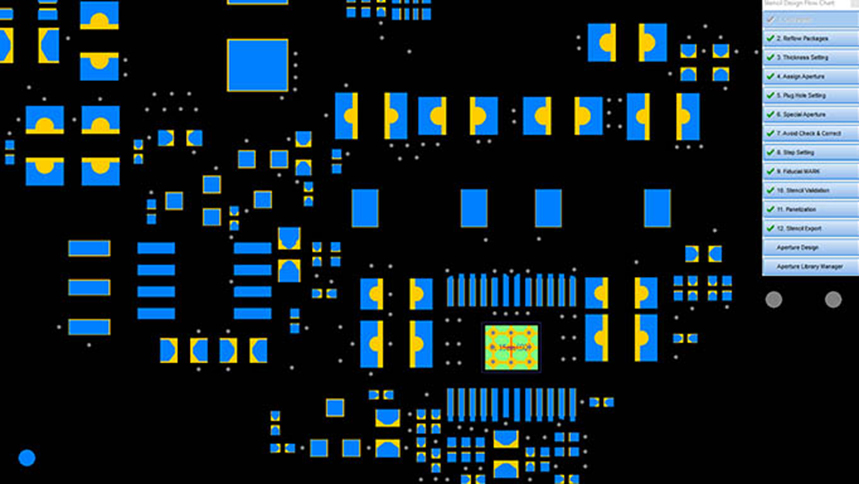

An SMT stencil is a thin metal sheet—usually stainless steel or nickel—designed with laser-cut openings that match the pads on a printed circuit board (PCB). Its main function is to ensure that solder paste is deposited in exactly the right place and in the right amount before component placement.

Common Types in the PCB SMT Stencils Market

-

Laser-Cut Stencils – Highly accurate and ideal for fine-pitch components.

-

Electroformed (E-Fab) Stencils – Known for exceptional paste release, used for BGAs and ultra-fine pitch designs.

-

Chemical-Etched Stencils – A more economical option for low-volume or less demanding projects.

Each option serves a different purpose in the pcb smt stencils market, and the right choice depends on the complexity of the design and production requirements.

Market Trends Driving Demand

The pcb smt stencils market has expanded rapidly in recent years. Several key factors are fueling this growth:

-

Miniaturization of devices – The rise of wearables, IoT, and compact consumer electronics demands precise solder paste application.

-

Automotive advancements – Safety systems, sensors, and autonomous driving electronics require stencils with tight tolerances.

-

Medical electronics – Devices with strict performance requirements rely on consistent and reliable solder joints.

-

Faster production cycles – Customers need quick prototyping and high-volume manufacturing without compromising quality.

Why SMT Stencils Matter in PCB Assembly

When it comes to PCB assembly, the stencil is more than just a tool—it is the foundation of a reliable soldering process.

-

Correct solder paste volume ensures strong and reliable joints.

-

High-quality apertures reduce defects like bridging and tombstoning.

-

Consistency improves production yield, especially with fine-pitch BGAs and QFNs.

In other words, the stencil directly impacts both product reliability and manufacturing efficiency.

PCBBUY’s Strength in the PCB SMT Stencils Market

PCBBUY has built a strong reputation in the pcb smt stencils market by offering precision-engineered solutions that align with the needs of global customers.

What We Offer:

-

High-Precision Laser Cutting – Apertures with micron-level accuracy.

-

Custom Thickness Options – Ranging from 0.08 mm to 0.20 mm for different assembly needs.

-

Smooth Aperture Walls – Ensuring clean solder paste release.

-

Flexible Formats – Frame and frameless stencils to support both prototypes and mass production.

By integrating stencil manufacturing with PCB production and assembly, PCBBUY helps customers reduce lead times, minimize costs, and maintain consistent quality.

Why Choose PCBBUY?

Here’s how PCBBUY stands out in the competitive pcb smt stencils market:

|

Feature |

PCBBUY Advantage |

|

End-to-End Service |

PCB fabrication, SMT stencils, and full PCBA assembly |

|

Precision Engineering |

±10 μm aperture accuracy with laser-cut stencils |

|

Customization |

Tailored solutions for prototypes, small batches, and volume orders |

|

Fast Global Delivery |

Reliable shipping and on-time delivery worldwide |

|

Strict Quality Control |

Compliance with IPC standards and detailed inspection |

Conclusion

The pcb smt stencils market is evolving rapidly, driven by the demand for greater precision, smaller components, and faster production. Choosing the right partner can make the difference between a smooth assembly process and costly rework.

With advanced manufacturing capabilities, strict quality assurance, and a one-stop production workflow, PCBBUY is well-positioned to deliver stencil solutions that meet the challenges of today’s electronics industry.

FAQ – PCB SMT Stencils Market

Q1: Which stencil type is best for fine-pitch components?

Laser-cut or electroformed stencils are recommended, as they ensure clean paste release and reduce soldering defects.

Q2: How do I choose the right stencil thickness?

It depends on the component types. Thinner stencils (0.1 mm) are better for fine-pitch parts, while thicker ones (0.15–0.2 mm) work for larger components.

Q3: Can PCBBUY handle both stencil production and PCB assembly?

Absolutely. PCBBUY provides PCB fabrication, stencil manufacturing, and SMT assembly under one roof, ensuring seamless production and faster turnaround.

Industry Category