PCB Silk Screen Printing Process

By:PCBBUY 08/30/2025 14:58

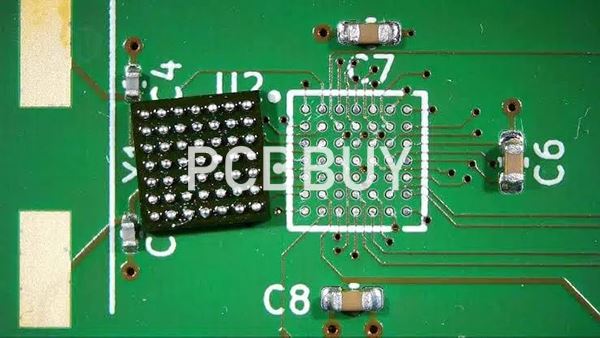

Introduction to PCB Silk Screen

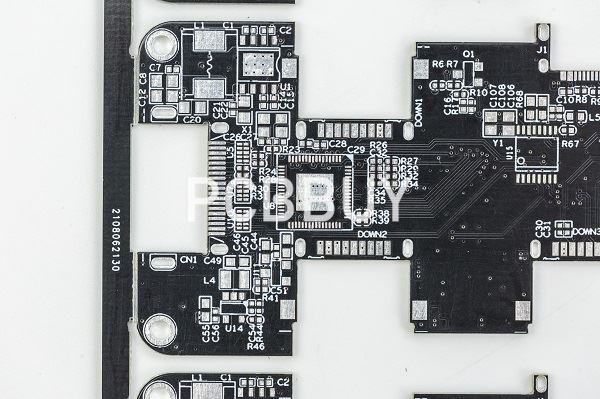

Pcb silk screen is a necessary procedure in the printed circuit board (PCB) manufacturing industry that extends past the eye to the electronic component. It offers the required identifiers of components, polarity marks, test points and business logos, which simplifies the assembly, inspection, and maintenance of a PCB significantly. The absence of an accurate and permanent silk screen can cause the engineers and technicians to incur problems in locating components and this can result in expensive mistakes in assembly.

We comprehend the essence of the importance of the silk screen technology in PCB fabrication at PCBBUY. Our pcb silk screen printing process is highly equipped with high quality control to achieve clarity, durability and consistency in all the customer orders.

The Role and Benefits of PCB Silk Screen

Pcb silk screen finish is not just a label, it has a critical role in the whole life cycle of electronic products:

• Improved Assembly Efficiency- The clear markings assist workers in putting together components fast and with great precision.

• Error Prevention - Labelling minimizes the chances of wrong component positioning.

• Easy Maintenance - Technicians can locate test points, connectors and replacement parts easily.

Brand Recognition- Providing company logos, QR codes and serial numbers enhances product traceability.

In the case of printing on silk screen, e.g., in industries with medical devices, automotive electronics, and industrial control systems, high quality silk screen printing is not an optional tool.

Common PCB Silk Screen Techniques

Pcb silk screen printing is accomplished in different ways according to the amount and nature of the required resolution, permanence, and scale of production:

1. Screen Printing - The most popular traditional process; epoxy ink and a mesh stencil; economical and easy to find.

2. Liquid Photo Imaging (LPI) - Photosensitive epoxy ink can be used and exposed to UV light, which enables a higher resolution.

3. Direct Legend Printing (DLP) - Inkjet-based digital printing, which is appropriate in complicated and thin designs.

|

Method |

Advantages |

Limitations |

|

Screen Printing |

Low cost, simple, suitable for mass use |

Limited resolution for fine text |

|

Liquid Photo Imaging |

High precision, durable, excellent for small fonts |

Higher cost and longer process |

|

Direct Legend Printing |

Fast, flexible, supports customization |

Ink adhesion may be less durable |

PCBBUY offers all three methods and recommends the most suitable pcb silk screen process depending on the customer’s product requirements.

PCB Silk Screen Materials and Standards

Pcb silk screen printing quality rides on the standards of ink and process:

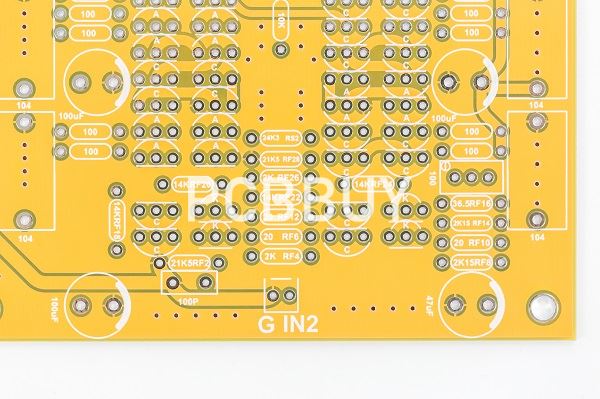

Materials - Inks that are based on epoxy and UV-curable inks are popular in high adhesion and chemical resistance.

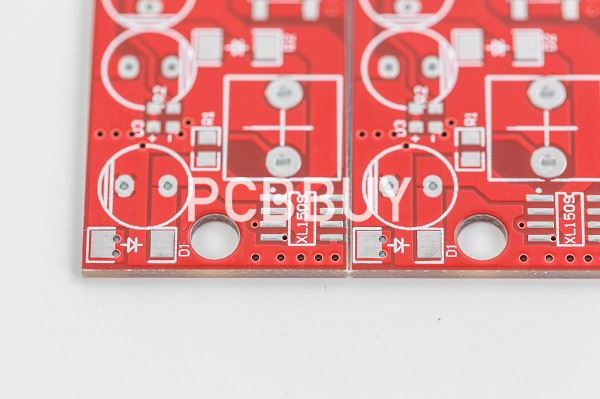

Colors - white is the most standard but there are also black and yellow colors to enhance contrast on solder mask color.

Industry Standards - PCBBUY is compliant with IPC-4781 standards, and every silk screen demonstrates international readability and durability standards.

Through stringent measures, PCBBUY ensures that pcb silk screen finish is clear and stable even at high-temperature soldering or working conditions.

PCBBUY’s Advanced PCB Silk Screen Process

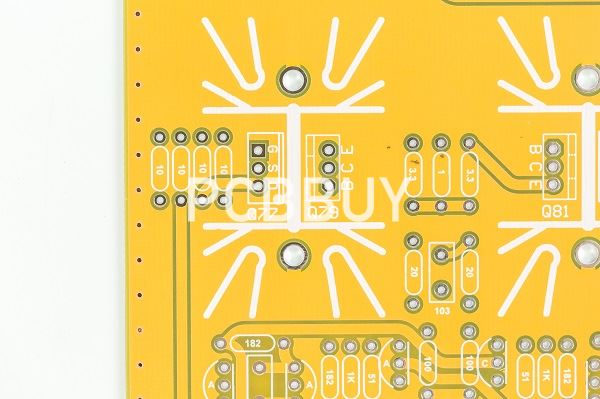

PCBBUY combines innovative technology with a high quality of inspection to provide high-quality silk screen output:

• Precision Printing- Text print to 4 mil and even smaller PCBs are readable.

• Material Flexibility – Multiple epoxy and UV inks to various customer requirements.

• Position Accuracy - Automated alignment ensures that there is no misregistration and placement is precise.

• Customization - The ability to include customer logos, QR codes and anti-copying marks.

• Quality Control AOI (Automated Optical Inspection) and a hand check prior to delivery.

PCBBUY guarantees quality in all its pcb silk screen printing processes and provides affordable prices and quick delivery due to years of experience in manufacturing.

Applications of PCB Silk Screen in Different Industries

PCBBUY offers pcb silk screen services to clients across a broad spectrum of sectors:

• Consumer Electronics – Smartphones, wearables, and smart home devices.

® Industrial Control - Controllers, automation devices and monitoring equipment.

• Medical Equipment - High-reliability boards that are to be clearly identified.

• Automotive Electronics – Safety-critical modules with strict labeling standards.

Our silk screen system guarantees that no PCB goes to waste and all of them are durable in long-term usage.

Why Choose PCBBUY for PCB Silk Screen

As far as choosing a pcb silk screen manufacturer is concerned, PCBBUY is a company with multiple advantages:

• State-of-the-art automated silk screen.

• Capability for both prototype and mass production.

• High-resolution and durable printing quality.

• Complete customization to branding requirements of the customers.

• Comprehensive one-stop PCB manufacturing and assembly services.

Selecting PCBBUY, the customer takes more than just the accuracy in PCB production, but gets a reliable partner, focused on quality, innovation and efficiency.

Conclusion

The pcb silk screen printing process is an indispensable step in modern PCB manufacturing. It improves assembly efficiency, reduces errors, and enhances long-term reliability. At PCBBUY, we combine advanced technology, high-precision equipment, and strict quality control to deliver silk screen finishes that meet the most demanding requirements.

If you are looking for a reliable pcb silk screen manufacturer, PCBBUY is your trusted partner for world-class PCB production.

Industry Category