PCB guidelines for the technology

By:PCBBUY 07/08/2021 17:18

As the development of PCB manufacturing,, we could find the products now are very different than before on performance and capability. And the customers and market have more and more requirements on PCB products and technology.

In this passage we will tell you everything about the PCB technology. If you are going to learn more professional knowledge, come and check the content we prepare below.

What are the applications of recent PCB?

The continuing demand for PCBs stems from their many uses. They exist in almost every electronic device you own. However, it is the advancement of certain technologies and gadgets that keep the printed circuit board in high demand. For example:

· Wireless headphones are incredibly useful for those who live an active lifestyle or want to be free of that long cable hanging from your ears.

· Smart Watches are made possible thanks to advancements in PCBs' size and are also a commodity.

· Smart Phones are not a new gadget, but every year, there is a better, more sophisticated model that will release, and this is thanks to improving PCBs.

· Smart technology is making huge steps in the technology world. You have voice-controlled speakers, smart TVs connected to your Wi-Fi. You have smart thermostats and electric meters at home to help you save on your household bills.

These are not all the devices that influence the high demand for PCBs. As mentioned above, they are in all-out electronic gadgets. However, it is the constant demand for high-quality, more sophisticated, and better-designed gadgets that will continue to keep the demand for PCBs in such a high number.

What is the evolution of PCB technology?

We see that everything is the beginning of an era of digitization, where comfort relies on electronics, where voice-operated gadgets are the norm. And this will only keep evolving. Society is demanding more and more gadgets designed to make our life easier. It could not have been made possible without the constant improvement of printed circuit boards. Their role is changing and becoming more important as society's need for creature comforts and easier life becomes apparent.

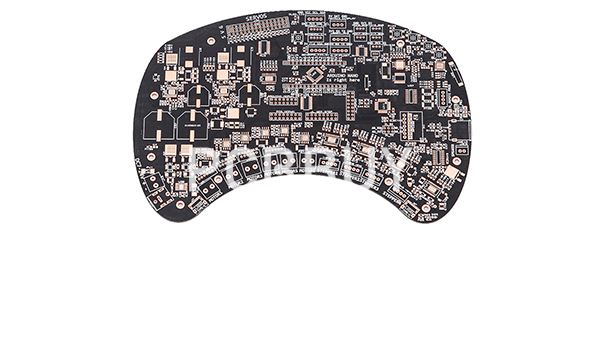

There is always room for improvement, even though PCBs of today are already incredibly complex. Different accessories attached directly to the board or the shape of the PCB itself are already in demand from consumers. These consumers are always pushing the limits for new PCBs and new functions. And they are getting new PCB functions.

PCB Board Cameras

PCB Board Cameras, also known as Board Cameras, are cameras attached directly to a PCB. They are simple cameras composed of a lens, aperture, and an image sensor, designed to take digital photos and videos. Because of their size, it means you can place the camera on any electronic device. See your smart hone next to you? That is a clear example. But they are developing at such a high rate that these cameras will soon have many more uses beyond just a simple smart hone. Their use in medical instruments for non-invasive and minimally invasive procedures is growing. Did you know that there is a pill-sized camera you can swallow so a doctor can get high-quality, high-resolution images of your digestive tract? And they can only get better.

Surveillance technology is also benefiting from board cameras. Because of their size, they can hide in more objects than ever before. And as their quality improves, so will their uses in the surveillance industry.

3D Printing

3D Printing has been one of the biggest technological inventions of the last decade. It was something we thought unattainable until recently. And of course, since the first 3D printer, they have been improving. You can now buy smaller printers that fit comfortably at home, cheaper, and eco-friendlier. As they continue to improve with novel designs, improved efficiency, and friendlier to the environment, PCBs will change with them. Thanks to 3D printers, there is now such a thing known as 3D-PE, 3D Printed Electronics. It is creating electronic components layer by layer with a 3D printer and adding ink on top that contains the electric functionalities. It can change the way of manufacturing a circuit board, as they can make to any shape and size you can imagine.

What is the future of PCB?

The future of PCBs beyond their uses in a constantly growing consumer electronic market lies in their production. Flexible and Biodegradable PCBs are the future for these boards. Flexible PCBs are estimated to grow faster than standard boards, reaching $15.2 billion by 2020, and $27 billion by 2022. It is due, in most part, to flexible displays and medical applications.

These types of PCBs can handle more stress and bending. Thus, being folded into awkward spaces and making them excellent for applications where frequent bending is involved. They are also lightweight and easy to mass-manufacture. Their applications include:

1. LED lighting, which because it is bright and eco-friendly, is incredibly popular. LED strips need flexible PCBs to operate but maintain the ability to bend to suit consumers' needs.

2. Wearable technology is also becoming reliant on flexible PCBs, with smart socks, wristbands, and belts needing to bend to fit the wearer. Flexible PCBs can handle the bending of these products and the vibrations and shock factors, as most wearable technology is to help in sports.

3. Flexible displays are yet to explode in a big way due to their manufacturing costs. However, once reduced costs with flexible PCB help, they will be the next important factor.

Potentially lead to flexible smart phone and tablets because of their ability to withstand shock and impact better than rigid displays.

4. Medical instruments are now focusing on minimalization and flexibility. And with the help of flexible PCBs, they can achieve both.

If these trends continue, you can expect to see a high rise in flexible PCBs' demand.

Biodegradable PCBs

Biodegradable PCBs is the industry's way of dealing with the major concern of e-waste, or electronic waste. Electronic scrapping is becoming more and more popular, but this waste still exists and is a problem that needs to be solved. Components of standard printed circuit boards do not degrade well and cause much of the problem. Furthermore, the chemicals used during the manufacturing process are harmful to the environment if not disposed of properly.

Industry Category