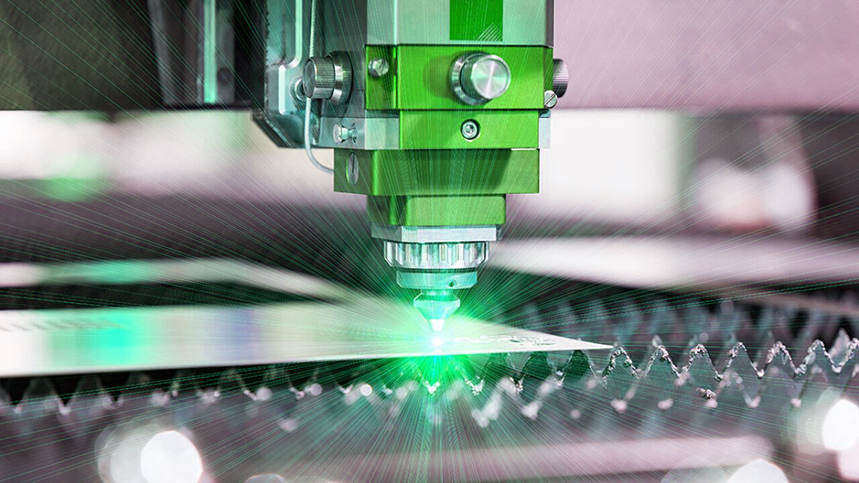

PCB laser drilling process

By:PCBBUY 08/16/2021 09:52

When using HDI technology for PCB designing, plenty of microvias are included. These microvias that appear to be blind structures are small in size and require precise controlled depth drilling. This precision can only be achieved using lasers. In this passage, we will focus on the PCB laser drilling topic and if you are going to learn more knowledge please check and read the content below.

What are the advantages of PCB laser drilling?

The advantages of using lasers are listed below:

· Non-contact process: Laser drilling is a non-contact process and hence the damage induced on the material by drilling vibration is eliminated.

· Precise control: We can control the beam intensity, heat output, and duration of the laser beam. This helps to create different hole shapes and offers high accuracy.

· High aspect ratio: One of the most important parameters of a drilled hole on a circuit board is the aspect ratio. It is the ratio between the drilled depth and the diameter of the hole. Since lasers can create holes with very small diameters, they provide a high aspect ratio. A typical microvia has an aspect ratio of 0.75:1.

· Multi-tasking: Laser machines used for drilling can also be used for other manufacturing processes like welding, cutting, etc.

Lasers can drill 2.5 to 3-mil vias on a thin flat glass reinforcement. In the case of an unreinforced dielectric (with no glass), it is possible to drill 1-mil vias using lasers. Hence, laser drilling is recommended for drilling microvias.

What are the methods of PCB laser drilling?

Single-pulse/shot laser drilling

As the name suggests, in single-pulse laser drilling, a single shot of laser beam is fired at the material to create the required hole. In this method, both the source of the laser and the work material is kept static.

Percussion laser drilling

In percussion drilling, a series of laser pulses are shot at the work material repeatedly. During this process, there is no relative motion between the laser beam and the workpiece. This form of laser drilling effectively creates deeper and precise holes with smaller diameters as compared to single-shot laser drilling.

Trepanning

Trepanning is the process in which a laser beam is guided around a predefined locus. This locus is the center of the via to be drilled. It is used in situations where the diameter of the via to be cut is larger than the laser beam diameter. The accuracy of the via is determined by the movement of the beam.

Helical laser drilling

Helical laser drilling is a method in which the laser beam follows a helical path for movement while rotating about its own axis with respect to the workpiece. A dove prism controls the movement of the laser beam.

What are the considerations of PCB laser drilling?

During laser drilling, there are a few aspects regarding the circuit board that should be considered. Given below are two of the important ones.

Non-homogeneity of the stack-up

The non-homogeneity of the PCB materials used in the stack-up is the main consideration while using lasers. Different materials absorb energy at different rates. For example, FR4 resin absorbs light energy at the same rate as the glass fibers and leaves a clean hole. BT epoxy resin vaporizes at a rate faster than glass and hence leaves glass fibers in the hole.

In situations like these, obtaining complete accuracy with lasers becomes difficult. Therefore, it is recommended to keep the homogeneity of the multilayer PCB stack-up as much as possible. If we use materials that have different optical and thermal properties, the way the laser beams react with them will also be different, leading to inaccurate drilling.

The thickness of copper

The minimum thickness of the target copper layer should be twice the thickness of the top copper layer to be penetrated.

Apart from a few challenges that may arise, we can surely say that lasers are the best choice to create microvias in PCBs. Given the ever-increasing demand for reducing the board size and increasing the wiring density, laser-drilled microvias are crucial in PCB manufacturing. Creating diminished holes with extreme accuracy without affecting the integrity of the board is a difficult task. Laser drilling is the best way to manufacture such compact boards.

Industry Category