PCB manufacturing cost breakdown

By:PCBBUY 07/09/2021 18:40

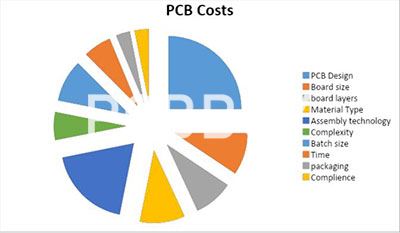

During the PCB manufacturing process, it is very important to know cost breakdown and finding the problems and solutions of it. The cost breakdown will influence the manufacturing costs while ensuring they maintain their quality. In this passage we will analyze the structure of PCB manufacturing cost and you will find more useful information.

What are the factors of PCB manufacturing cost breakdown?

Do you want to reduce your PCB manufacturing costs? Abiding by the following rules of the thumb can help you mitigate such costs. Here is what you need to need to do to cut down your PCB manufacturing costs.

Circuit board size

How big or small do you want your boards to be? If you manufacture large panels, then you’ll incur huge costs. Without a doubt, the size of the board will affect how much you’ll have to incur manufacturing them.

Among other things, PCB cost production depends on the size of your boards. A 14 X 18 board will be cheaper to produce compared to a 16 X 22 board. Huge boards will require many raw materials. All this will see you incurring extra costs. Ultimately, the dimension of your printed circuit board is a determining factor of its overall price. Huge boards contain several columns, meaning that it will cost you more.

If you want to minimize costs, you may have to consider reducing the size of your boards. But again, all this depends on your budget. If you aren’t on a budget as such, then the board’s size doesn’t matter as such.

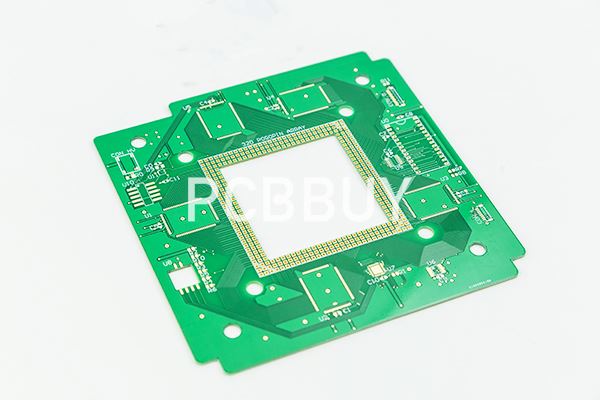

Circuit board layers

Another huge determining factor that will see you incur extra PCB manufacturing costs is the number of layers your board has. For obvious reasons, panels with three or more layers will cost more to manufacture than those with merely two layers. In addition to the types of materials used, the size of the board affects its overall price. Generally, thick boards with several layers require a lot of work to manufacture.

Costs tend to increase the moment you add a second layer to your board. From there, an additional two panels then raises the cost by at least one-third of the price you paid before. The price continues to increase the moment you add more layers to your board. Every layer demands more production steps, especially in the lamination process. Therefore, it means more time required to achieve, in addition to a larger supply of raw materials.

Depending on where you want to use your board, you may have some that require more layers. With additional layers, you’ll incur more. If your PCB endures high amounts of stress, its layer count will matter. That way, you should be prepared to pay more.

PCB design service

If you choose high-end design services, you will have to spend more since high-quality PCB design services are expensive. The moment you decide on other complementary services, you will incur additional costs. Extra services that you may have to undertake include PCB testing and prototyping before manufacture. You need to know that each other use adds to extra some additional costs.

To maximize your cost savings, you may have to reduce extra PCB design services. Design services cost more. The more services you put in, the more you’ll incur. Even though you don’t need to compromise on quality, you may have to limit the number of services you put in.

Some design services will cost more. If you source such services from experts, then you will have to dig deeper into your pockets. At times, you may require advanced PCB design software for your design. If that’s the case, then the costs will undoubtedly increase.

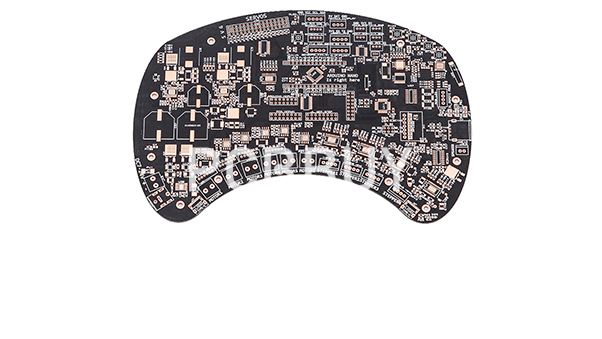

Board material and component material

The components and materials that go into the manufacture of your PCBs will affect its overall costs. In the manufacture of PCBs, you’ll require many materials. Some of them include copper foils, Solder mask, vocabulary, and the final finish; the more board materials that you choose to use means, the more costs that you’ll have to incur.

Materials aren’t the only thing. The components that you’ll use will determine how much you will have to incur. The materials that you choose to use will invariably affect the cost of your boards. Some of the factors that affect material selection include thermal reliability, heat transfer, and signal performance. Others have mechanical properties and temperature reliability of the materials you choose.

Therefore, in addition to component material, board material will have an impact on the cost of your printed circuit boards. If you go for high-quality materials, then expect to pay more. It’s as simple as that.

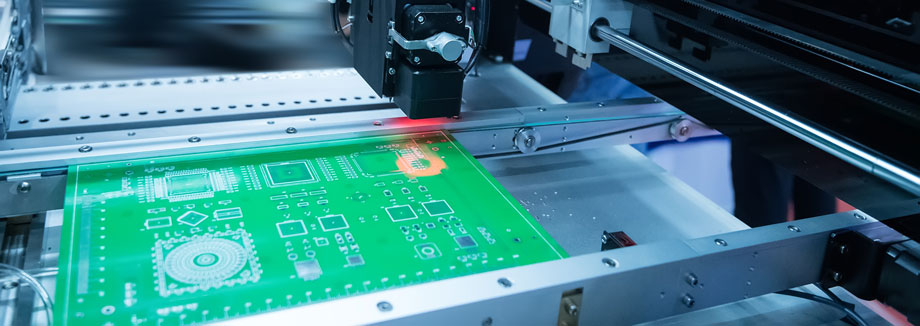

PCB assembly technology

PCB assembly technology mostly consists of Surface Mount Technology (SMT) and Through-hole technology. Are you a PCB manufacturer to scale down your manufacturing costs when it comes to PCB production technology? If that’s the case, you may want to think of using Surface Mount Technology instead of through-hole technology. Surface Mount Technology is highly efficient and cost-effective. If you resort to SMT technology, you’ll save a lot compared to THT technology. Surface mount technology is cheaper compared to other technologies. If though the results may not be perfect, its costs are slightly on the lower side.

The degree of design complexity

The complexity of your design will ultimately cost you more. If the design of your PCB is involved, then you’ll have to pay more. PCB design may be complicated, especially with the addition of more layers. Such may demand more technique and practice. If you want to minimize your PCB manufacturing costs, then you may want to reduce the degree of design complexity. Intricate designs are always expensive.

They demand a lot of work and many hours. If you choose intricate PCB designs, then rest assured that you will pay more. Complex systems consist of many tracks and may require professional mounting methods. Designing complex PCBs is not an easy process as such. It calls for a lot of time and extra expenses.

Production batch size

How many PCBs are you going to produce? Apart from the above, your PCBs’ batch size will impact the costs that you’ll have to incur. If you manufacture a large number of PCBs, then you’ll have to incur more charges. Again, for obvious reasons, the production batch size will impact the values you incur. Large batches increase the average inventories that you’ll require. That translates to increased costs as a PCB manufacturer. It is important to note that if your PCB batch size is large, then the manufacturing costs will be high.

Turnaround time

Turnaround time (TAT) is the time interval taken from submitting a process to the time that the entire process will end. In other words, it’s the time taken from when you get to place an order for something to the time that such an approach will end. So, how fast do you want your PCBs delivered to you?

If you want them within the shortest time possible, then you’ll have to spend a little bit more. But why, you ask. It’s because the firm may have to put other things on hold. Your producer may have to stop or slow other processes to handle your order. If you are a PCB manufacturer with little time to deliver, you’ll incur some extra costs. You may have to request some of your staff to work extra hours or at odds hours. Such will see you incurring additional costs. If you want to produce your PCBs fast, then be prepared to incur additional charges.

Packaging selection

What type of packaging do you want for your PCBs? Cheap or expensive? If you choose high-end packaging, then you’ll have to incur more costs. Packaging plays an important factor in price. The reason is that packaging increases the total cost of a product. If you want to reduce the value of the overall PCB manufacture, then you may have to reduce the quality of your packaging selection.

Packaging adds value to a product in both invisible and visible ways. If the packaging is proper to prevent damage during transit or storage, then the costs will increase. Appropriate packaging is essential. It improves the image of your company. However, you need to be aware that your packaging selection will have significant impacts on the costs.

How to save cost from PCB manufacturing cost breakdown?

Do you want to save costs from PCB manufacturing? Apart from the above, you may have to consider the following cost reduction measures:

Number and size of holes on the board

The number and the size of holes that you’ll want on your board will increase its costs. If you choose to have many holes on your board, then you’ll incur increased production costs. Additionally, if the holes’ sizes tend to be large, rest assured of additional manufacturing costs.

Large holes demand the use of advanced equipment. If the holes are large, rest assured of increased manufacturing costs. But also, if they are small, it may demand a lot of precision. If you intend to save costs, you may want to reduce your board’s holes’ number and size. Unless you are not on a budget, many spots on the board will see you spending more.

Trace width (signal conductor)

Trace width is one of the most critical design parameters in the design of a PCB. Adequate trace width is necessary to ensure the transportation of the desired amount of current. All this must take place without overheating or damaging the board. Trace widths will affect the cost of your PCBs. If you choose wide PCB traces, then you’ll have to pay more. Enlarged trace widths will surely cost more; enlarged trace widths demand extra solder mask to the trails. Such may see you spending slightly more.

Custom specifications

Customized goods cost more. Many things go into customization, a reason as to why personalized goods will cost more. The same is true when it comes to the manufacture of PCBs. Custom specifications on a PCB will see its manufacturing costs increase. If you want to reduce your PCB manufacturing costs, you may have to limit matters to customization.

For custom specifications or exclusive products, expect to pay more. To save costs from PCB manufacturing, you may have to limit custom specifications. Special features always call specialized skills. If your design requires details that are hard to produce, then you should expect increased costs. Mostly, special tools are often a necessity when designing unique boards. Such will see you spending more.

Inspection and testing

Finally, yet significantly, inspection and testing will increase your PCB manufacturing costs. Tests and assessments are essential. They help in detecting errors early before mass production. The same is true when it comes to PCBs. Examination and tests ensure the production of high-quality PCBs. However, with inspection and tests, expect increased PCB costs. Do you want to reduce difficulties and inspection costs? If so, then it’s better to stick with a single PCB assembler. That way, you’ll ensure that you roll out high-quality PCBs but at the lowest price. While you’ll be able to cut costs, you’ll do so without sacrificing the quality of your products.

Industry Category