PCB pinhole removal kick

By:PCBBUY 12/15/2023 09:34

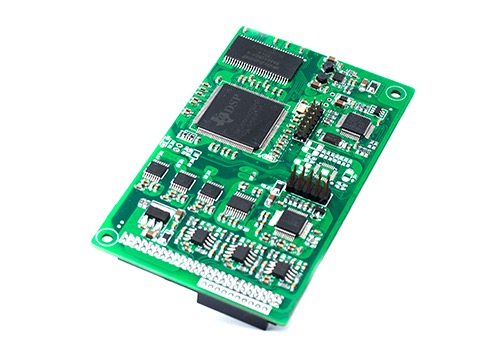

The pinhole issue has long been a challenging problem in the electronic manufacturing industry, impacting both the quality and performance of circuit boards and potentially causing their failure. In addition to previously mentioned solutions like improving hole design, increasing preheat time, and controlling solder temperature, the "kick-out method" is another common approach.

-

Principle of the Kick-Out Method The kick-out method involves mechanically pressing the solder around the pinhole, pushing it into the hole to eliminate the pinhole. By exerting pressure around the pinhole, the solder is pushed from the surface around the hole, effectively filling it. This method efficiently eliminates pinholes on circuit boards, enhancing their quality and performance.

-

Implementation Steps of the Kick-Out Method Preparation: Before employing the kick-out method, thorough preparation is necessary. Firstly, assess the number and distribution of pinholes on the circuit board to determine their locations and quantity for treatment. Then, prepare the required tools and equipment such as needles, fixtures, magnifiers, etc.

-

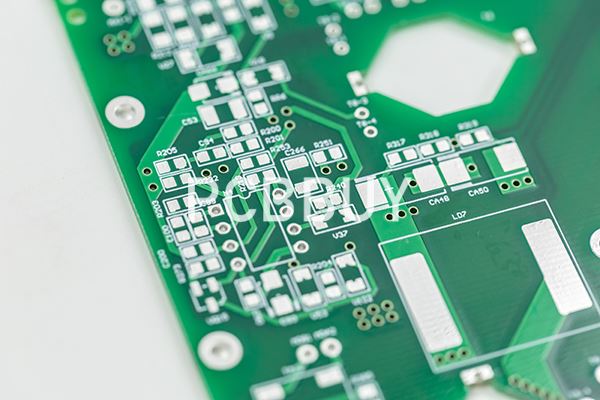

Pinhole Localization: Using a magnifier or other inspection tools, locate the pinholes on the circuit board precisely to determine the specific pinholes to address. This process requires careful and patient examination to ensure accurate identification of all pinholes.

Kick-Out Implementation: Use needles or suitable tools to exert pressure around the pinhole, squeezing the solder from the surface around the pinhole into the hole. This process necessitates controlled force and direction to prevent damage to the circuit board. Additionally, fixtures or other securing devices should be used to immobilize the board during the process, ensuring it remains stable.

Inspection of Results: Following the kick-out process, inspect the board to ensure all pinholes have been effectively eliminated. This inspection can be conducted using a magnifier or other inspection tools. If any pinholes persist, additional treatment or other methods should be applied.

-

Advantages and Disadvantages of the Kick-Out Method Advantages:

-

Simple operation: The kick-out method is relatively straightforward, requiring only proper tool and equipment preparation for implementation.

-

Significant effects: This method efficiently eliminates pinholes on circuit boards, enhancing their quality and performance.

-

Lower cost: Compared to other solutions, the kick-out method involves relatively lower costs, requiring minimal materials and equipment investment.

Disadvantages:

-

Operational risks: As the kick-out method involves mechanically pressing solder to eliminate pinholes, there's a risk of damage if force or direction isn't well-controlled.

-

Unstable effectiveness: Due to variations in pinhole size and distribution, the effectiveness of the kick-out method may vary, and some pinholes might not be completely eliminated.

-

High operator skill requirement: Successful implementation of the kick-out method requires operators to possess specific skills and experience. Otherwise, damage to the circuit board or poor outcomes may result.

-

Conclusion The kick-out method stands as an effective means to address pinhole issues on circuit boards but has limitations and inherent risks. Hence, before employing this method, thorough preparation and risk assessment are essential. Choose appropriate tools and equipment for the operation and continuously improve the operator's skills and experience to ensure implementation effectiveness and quality.

Industry Category