Pcb Assembly BGA with Precision and Challenges

By:PCBBUY 09/29/2025 15:05

When it comes to advanced electronics, Pcb assembly BGA (Ball Grid Array) has become a cornerstone technology. Whether in smartphones, automotive systems, data servers, or telecom devices, BGA packaging allows engineers to combine compact size with high performance. However, the process demands exceptional precision. At PCBBUY, we have built strong expertise in handling BGA assemblies, backed by advanced machinery and a well-trained engineering team that ensures every joint is reliable.

What Exactly is BGA in PCB Assembly?

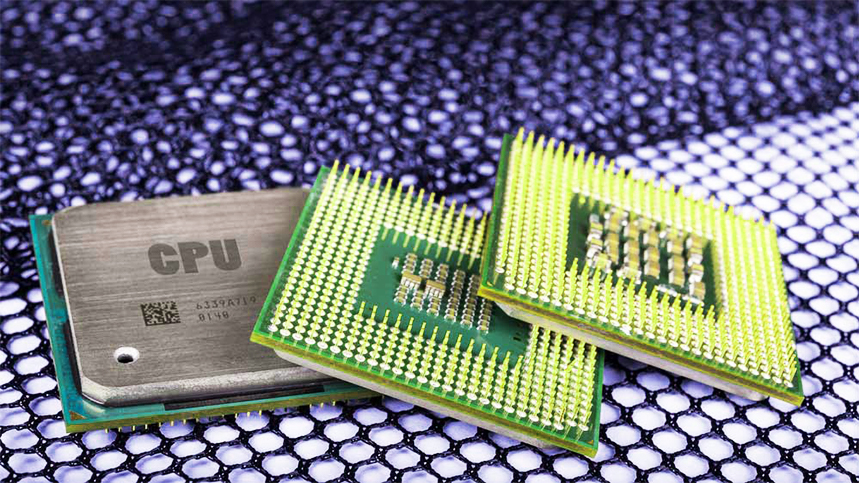

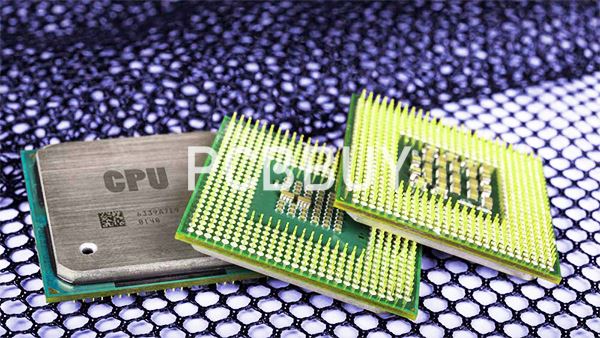

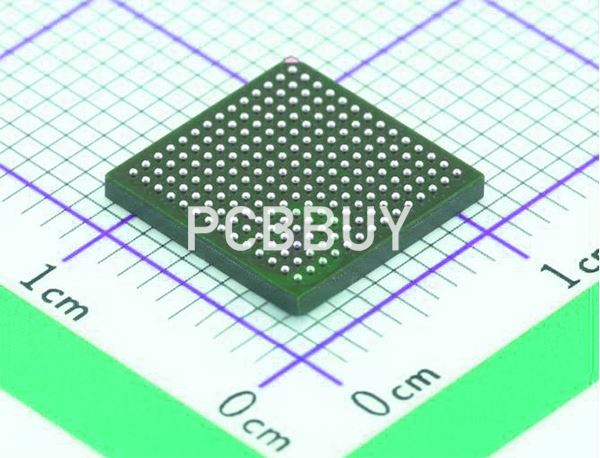

BGA, or Ball Grid Array, is a type of component packaging where tiny solder balls are arranged in a grid under the chip. These balls act as the connection points to the PCB, replacing the older pins used in QFP or SOP packages.

The advantages of BGA are clear:

-

Higher density – more connections in less space.

-

Better performance – shorter paths reduce signal loss.

-

Improved heat dissipation – ideal for high-power devices.

This makes Pcb assembly BGA a preferred choice whenever both miniaturization and performance are critical.

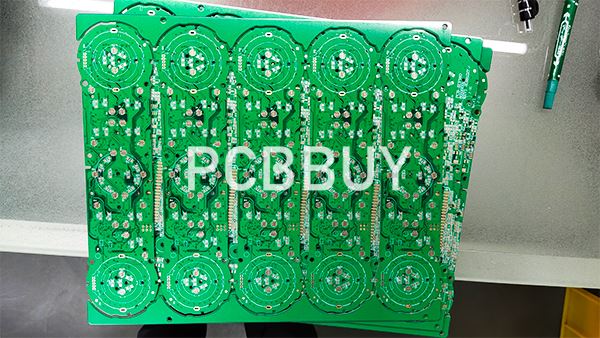

The Pcb Assembly BGA Process at PCBBUY

1. Solder Paste Application

The process begins with printing solder paste on the pads. At PCBBUY, we use laser-cut stencils and fully automated printers to guarantee even, accurate paste distribution. This step is vital, as uneven paste can lead to weak solder joints.

2. Pick and Place

BGA components require near-perfect accuracy. Our high-speed SMT machines are capable of placing BGAs with pitches as fine as 0.25mm. This precision ensures each solder ball is aligned correctly with the PCB pad.

3. Reflow Soldering

The boards then move into multi-zone reflow ovens, where controlled heating profiles melt the solder balls and form solid electrical and mechanical connections. PCBBUY engineers fine-tune reflow curves to ensure defect-free joints, whether for leaded or lead-free solder.

4. Inspection and Quality Check

Since BGA solder joints are hidden underneath the chip, standard inspection methods are not enough. At PCBBUY, we rely on 3D AOI and X-ray inspection systems to examine every joint, detecting possible voids, bridges, or misalignments before boards are shipped.

Common Challenges in Pcb Assembly BGA

Despite its advantages, BGA assembly does present some difficulties:

-

The hidden solder joints require X-ray inspection.

-

Voids or cold soldering can affect long-term performance.

-

Ultra-fine pitch BGAs demand strict process control.

-

Reworking a BGA is complex, as removing and reballing requires specialized tools.

These are challenges PCBBUY is well-prepared for, thanks to advanced inspection equipment and a skilled engineering team.

Why PCBBUY Excels in Pcb Assembly BGA

At PCBBUY, we treat Pcb assembly BGA with the precision it deserves. Our capabilities include:

-

High-end SMT machines for fine-pitch BGAs.

-

100% X-ray inspection for every BGA joint.

-

Rework and reballing expertise, extending board usability.

-

Experience with advanced PCBs such as HDI, rigid-flex, and high-frequency boards.

-

End-to-end support – from PCB fabrication to sourcing, assembly, and testing.

Over the years, PCBBUY has delivered BGA assembly services for industries including automotive, consumer electronics, data communication, and industrial automation.

Why Choose PCBBUY as Your BGA Assembly Partner?

Selecting the right partner for Pcb assembly BGA is critical. PCBBUY offers:

-

One-stop turnkey service – all stages covered under one roof.

-

Strict quality control – IPC-A-610 Class II/III compliance.

-

Scalability – from small-batch prototypes to mass production.

-

Global reach – fast delivery and competitive pricing for international customers.

With PCBBUY, you are choosing reliability, expertise, and a long-term manufacturing partner.

Conclusion

BGA technology has transformed modern electronics, but it also requires expertise to handle correctly. At PCBBUY, we combine advanced equipment, a highly skilled team, and strict inspection standards to deliver reliable Pcb assembly BGA solutions.

From prototyping to full-scale production, PCBBUY ensures that every project is handled with care, precision, and consistency.

FAQ

Q1: What is the smallest BGA pitch PCBBUY can assemble?

We can handle BGA packages with pitches as fine as 0.25mm, supported by precision placement and reflow systems.

Q2: How does PCBBUY verify BGA soldering quality?

We use 3D AOI and advanced X-ray inspection to check every BGA joint, ensuring long-term reliability.

Q3: Can PCBBUY perform BGA rework or repair?

Yes, our dedicated BGA rework stations allow us to reball and repair BGAs, saving costs and extending the life of your boards.

Industry Category