Plated Through Hole Copper Thickness Explained Simply

By:PCBBUY 12/22/2025 16:38

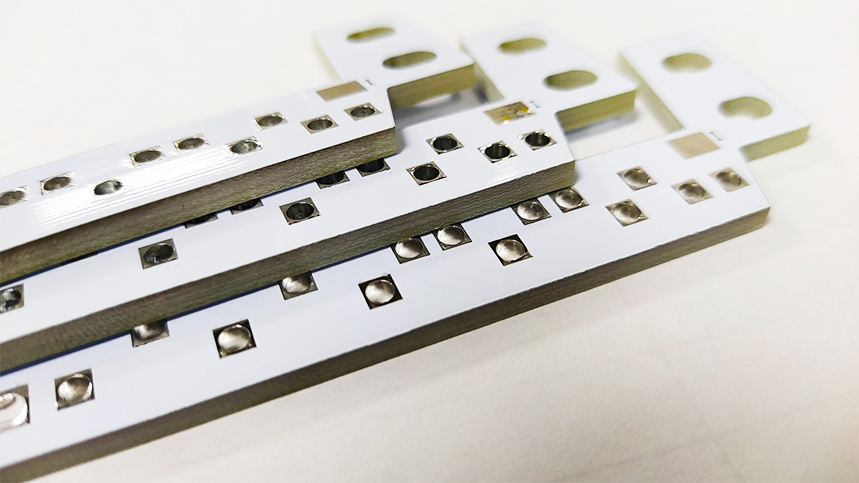

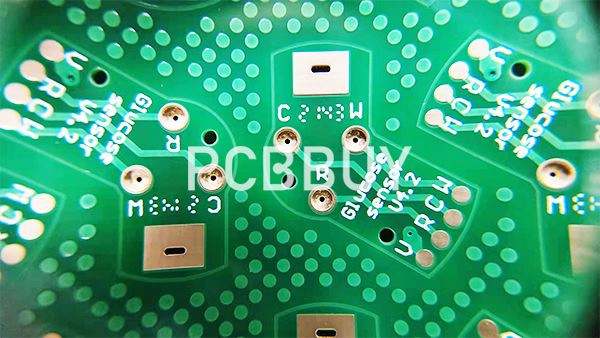

Plated through hole copper thickness refers to the thickness of copper deposited on the inner wall of drilled holes during the PCB electroplating process.

This copper layer creates reliable electrical connections between different PCB layers and directly affects mechanical strength, current-carrying capacity, and long-term reliability.

In multilayer PCB manufacturing, controlling hole copper thickness is one of the most critical quality indicators, especially for high-reliability applications such as industrial control, automotive electronics, and power boards.

Why Plated Through Hole Copper Thickness Matters?

-

Electrical Reliability

Insufficient copper thickness can lead to high resistance, unstable signals, or even open circuits under thermal stress. -

Mechanical Strength

Adequate copper thickness prevents barrel cracking during thermal cycling, soldering, and long-term operation. -

Current Carrying Capability

Thicker copper in plated through holes improves current capacity, which is essential for power PCBs and high-current designs.

Typical Hole Copper Thickness Requirements

Most PCBs follow IPC standards:

-

Standard PCBs: around 20 μm

-

High-reliability PCBs: 25 μm or more

For power boards or industrial designs, customers often request thicker hole copper for extra safety margin.

PCBBUY’s Hole Copper Plating Capability

PCBBUY uses stable and mature plating processes to ensure:

-

Even copper thickness from top to bottom of the hole

-

Strong adhesion between copper and hole wall

-

Consistent quality from prototype to mass production

We can support custom plated through hole copper thickness based on your design and application needs.

When Should You Specify Thicker Hole Copper?

You should consider enhanced hole copper thickness if your PCB is used for:

-

High current or power applications

-

Automotive or industrial environments

-

Multilayer boards with frequent thermal cycling

PCBBUY’s engineering team can review your Gerber files and recommend the optimal hole copper thickness.

FAQ

What is plated through hole copper thickness?

Plated through hole copper thickness refers to the thickness of copper deposited on the inner walls of PCB holes during electroplating, ensuring electrical and mechanical connections between layers.

What is the standard hole copper thickness in PCB manufacturing?

According to IPC standards, typical plated through hole copper thickness is 20 μm for Class 2 and 25 μm for Class 3 PCBs.

Why is plated through hole copper thickness important?

It affects electrical reliability, mechanical strength, current capacity, and resistance to thermal stress.

Can PCBBUY customize hole copper thickness?

Yes. PCBBUY supports customized plated through hole copper thickness for high-reliability, power, and industrial PCB applications.

How does PCBBUY ensure consistent hole copper thickness?

Through controlled electroplating processes, optimized current density, and cross-section inspection during production.

Industry Category