Plated Through Hole Copper Thickness in Reliable PCB Manufacturing

By:PCBBUY 12/19/2025 17:18

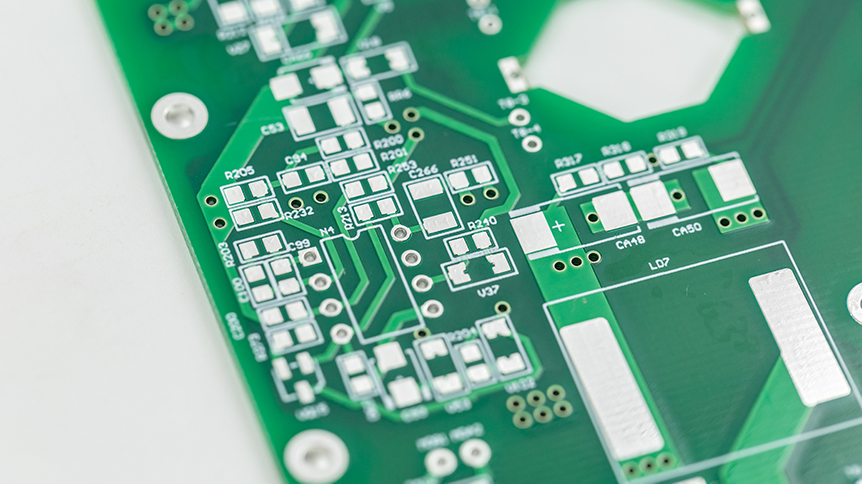

In PCB manufacturing, plated through hole copper thickness is one of those details that rarely appears in product brochures—but it plays a critical role in long-term reliability. From signal integrity to mechanical strength, the quality of copper plating inside through holes directly affects how a PCB performs in real-world applications.

At PCBBUY, plated through hole copper thickness is treated as a core process parameter rather than an afterthought. This article explains what it is, why it matters, and how professional PCB manufacturers control it throughout production.

What Is Plated Through Hole Copper Thickness?

Plated through hole copper thickness refers to the thickness of the copper layer deposited on the inner wall of a drilled hole. This copper forms a conductive barrel that electrically connects different layers of a multilayer PCB.

It is important to note that plated through hole copper thickness is different from outer layer copper thickness. Even when surface copper meets specifications, insufficient copper inside the hole can still lead to reliability issues.

Why Plated Through Hole Copper Thickness Is Critical?

Adequate plated through hole copper thickness ensures:

Strong mechanical bonding between layers

Resistance to thermal cycling and soldering stress

Stable electrical conductivity over time

Reduced risk of barrel cracking or intermittent failures

In applications such as industrial control, automotive electronics, or power systems, poor control of PTH copper thickness often becomes the root cause of early product failure.

Typical Standards for Plated Through Hole Copper Thickness

Industry standards commonly reference IPC Class 2 and Class 3 requirements. While exact values vary by application, most customers specify a minimum finished copper thickness inside the hole to ensure reliability.

At PCBBUY, customer requirements for plated through hole copper thickness are reviewed during engineering evaluation to ensure the design can be manufactured consistently.

How Plated Through Hole Copper Thickness Is Achieved in Manufacturing?

Drilling and Hole Preparation

Accurate drilling and proper desmear processes are essential. Clean, uniform hole walls allow copper to bond evenly during plating.

Electroless Copper Deposition

A thin electroless copper layer is first applied to create a conductive base. This step is critical for ensuring complete coverage inside the hole.

Electroplating Control

Electroplating builds up the final plated through hole copper thickness. Current density, plating time, and solution chemistry are carefully controlled to achieve uniform copper distribution.

PCBBUY’s Control of Plated Through Hole Copper Thickness

PCBBUY uses dedicated electroplating lines designed for consistent PTH copper thickness across the entire panel. Process parameters are optimized based on board thickness, hole diameter, and aspect ratio.

In-process inspections and cross-section analysis are used to verify plated through hole copper thickness before boards move to the next production stage.

Aspect Ratio and Its Impact on PTH Copper Thickness

High aspect ratio holes are more challenging to plate evenly. As board thickness increases and hole diameter decreases, maintaining consistent copper thickness becomes more difficult.

PCBBUY’s engineering team reviews high aspect ratio designs and provides DFM feedback when necessary to ensure stable plated through hole copper thickness.

Common Problems Caused by Insufficient PTH Copper Thickness

Barrel cracking during thermal cycling

Increased electrical resistance

Intermittent connectivity after assembly

Reduced product lifespan

These issues are often invisible during early testing but can appear months or years later in the field.

How to Specify Plated Through Hole Copper Thickness?

When ordering PCBs, customers are encouraged to clearly specify minimum plated through hole copper thickness in fabrication notes. PCBBUY engineers review these requirements and confirm manufacturability before production begins.

Why Choose PCBBUY for Reliable PTH Copper Thickness

With stable plating processes, experienced engineers, and strict quality control, PCBBUY delivers PCBs with consistent plated through hole copper thickness for both standard and high-reliability applications.

FAQ

What is the minimum plated through hole copper thickness for PCBs?

The minimum plated through hole copper thickness depends on the application and reliability requirements. For most commercial PCBs, manufacturers follow IPC Class 2 guidelines, while high-reliability products often require Class 3 standards. At PCBBUY, minimum PTH copper thickness is reviewed during engineering evaluation to ensure it meets both industry standards and customer specifications.

Why is plated through hole copper thickness more important than surface copper thickness?

Surface copper thickness mainly affects trace current capacity, while plated through hole copper thickness determines the strength and reliability of interlayer connections. Even if the outer layers meet copper specifications, insufficient copper inside the hole can lead to barrel cracking, intermittent connections, and long-term reliability issues.

How does hole aspect ratio affect plated through hole copper thickness?

Higher aspect ratio holes are more difficult to plate evenly. As board thickness increases or hole diameter decreases, achieving uniform copper thickness becomes more challenging. PCBBUY evaluates aspect ratio during DFM review and may recommend design adjustments to ensure consistent plated through hole copper thickness.

How does PCBBUY verify plated through hole copper thickness during production?

PCBBUY uses in-process inspection and cross-section analysis to measure plated through hole copper thickness. These inspections help confirm that copper distribution inside the hole meets required specifications before the boards proceed to final processing.

Industry Category