SMD vs SMT vs THT Understanding PCB Assembly Technologies

By:PCBBUY 09/26/2025 17:02

In the world of modern electronics, PCB assembly relies on three main methods: SMD, SMT, and THT. While these terms are often used interchangeably, they describe different aspects of the assembly process. Understanding their differences helps engineers and buyers choose the right solution for their projects.

As a trusted China-based PCB manufacturer and assembler, PCBBUY provides advanced capabilities in all three methods. In this article, we will break down the distinctions between SMD vs SMT vs THT, discuss their advantages, and explain how PCBBUY ensures high-quality production.

What Does SMD Mean in PCB Assembly?

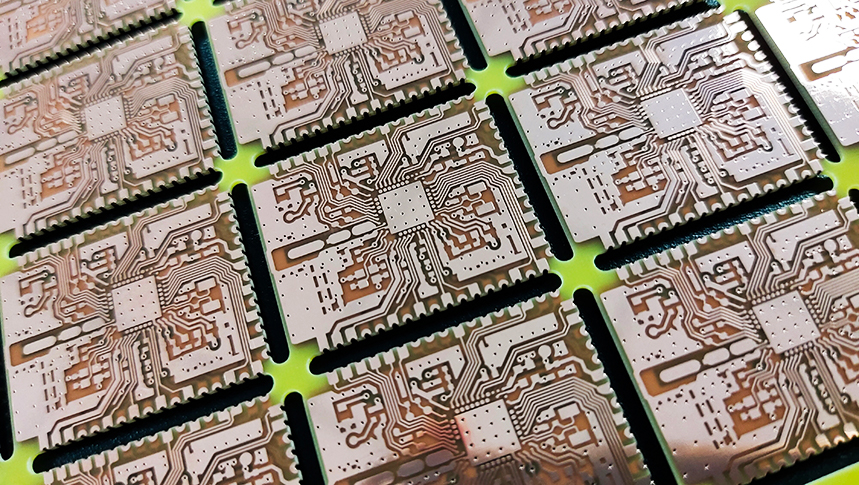

SMD (Surface Mount Device) refers to the electronic components that are mounted directly onto the surface of a printed circuit board. Unlike traditional components with leads that pass through holes, SMDs are smaller and lighter.

Typical SMD components include:

-

Resistors

-

Capacitors

-

ICs (Integrated Circuits)

-

LEDs

Because of their compact size, SMD components are ideal for modern electronic devices that require miniaturization, such as smartphones, wearables, and IoT devices.

What Is SMT and How Does It Differ from SMD?

SMT (Surface Mount Technology) is the process used to place and solder SMD components onto a PCB. It includes automated equipment, solder paste application, reflow soldering, and quality inspection.

At PCBBUY, our SMT production lines feature:

-

Automated pick-and-place machines with high-speed precision

-

X-ray inspection systems for fine-pitch and BGA components

-

Reflow ovens with controlled thermal profiles to ensure reliable solder joints

In short:

-

SMD = the part

-

SMT = the process of assembling that part

What Is THT in PCB Assembly?

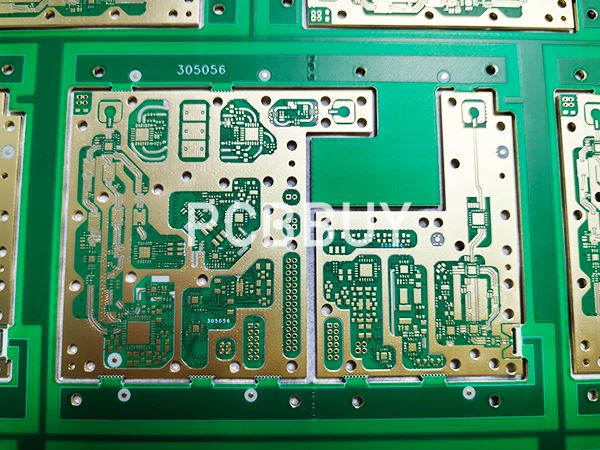

THT (Through-Hole Technology) is the traditional method of inserting component leads through drilled holes in the PCB and soldering them on the opposite side.

THT is often chosen when:

-

The PCB must withstand mechanical stress

-

High power or high current flow is required

-

Components such as connectors, large capacitors, or transformers are used

PCBBUY’s THT assembly lines use both wave soldering and manual soldering techniques, ensuring strong and durable connections for industrial and automotive applications.

SMD vs SMT vs THT: A Direct Comparison

|

Feature |

SMD (Component) |

SMT (Process) |

THT (Process + Component) |

|

Definition |

The physical device mounted on PCB |

Technology to assemble SMD parts |

Leads go through PCB holes and soldered |

|

Size & Weight |

Very small and lightweight |

Works with compact devices |

Larger, heavier components |

|

Assembly Method |

Requires SMT process |

Automated placement + reflow soldering |

Manual or wave soldering |

|

Strength |

Moderate mechanical durability |

Depends on solder joints |

Very strong, suitable for heavy-duty use |

|

Typical Applications |

Smartphones, IoT, wearables |

High-density boards, consumer devices |

Automotive, aerospace, industrial boards |

Why PCBBUY Excels in All Three Methods

Choosing between SMD vs SMT vs THT depends on product requirements. At PCBBUY, we provide flexibility by supporting:

-

Full SMT assembly for compact, high-speed designs

-

Dedicated THT assembly for durable and power-heavy boards

-

Mixed assembly (SMT + THT) to balance miniaturization and reliability

Our production facilities follow ISO9001, RoHS, and IPC standards, ensuring every board meets strict quality requirements. With strong supply chain partnerships, PCBBUY delivers competitive pricing, fast lead times, and engineering support for customers worldwide.

FAQ: SMD vs SMT vs THT in PCB Assembly

1. Are SMD and SMT the same thing?

No, they are not the same. SMD refers to the components (Surface Mount Devices), while SMT is the technology or process used to mount those components onto the PCB.

2. When should I choose THT instead of SMT?

THT (Through-Hole Technology) is best when your product requires strong mechanical bonding or must handle higher power. For example, connectors, large transformers, and industrial-grade boards often use THT because the leads pass through the PCB, making them more durable under stress.

3. Can PCBBUY provide mixed-technology assembly (SMT + THT)?

Yes. PCBBUY specializes in mixed-assembly solutions, where both SMT and THT processes are combined in one board. This ensures high performance for complex products—miniaturization through SMT, plus durability and power handling via THT.

Industry Category