SMT Defects Troubleshooting Ensures Reliable PCBA Quality

By:PCBBUY 10/23/2025 17:16

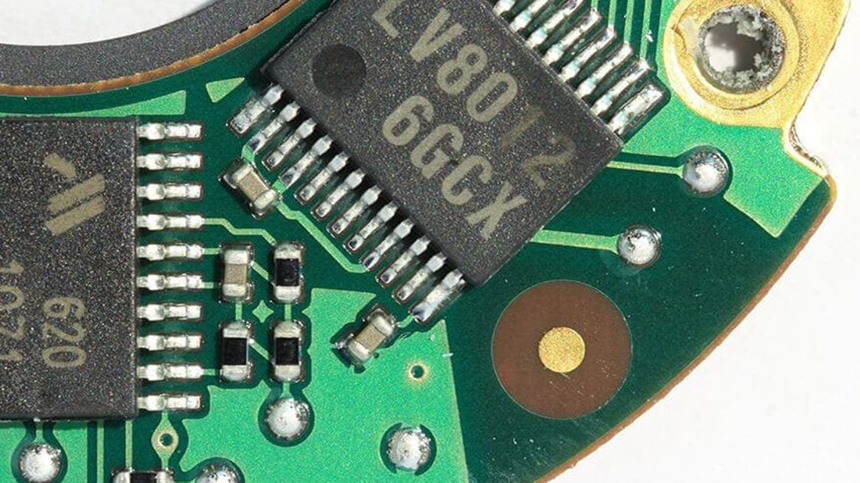

In the fast changing field of electronics manufacturing, the systematic study of the Surface Mount Technology (SMT) defects is a decisive factor of the product reliability and performance. Surface Mount Technology is the core of the process of modern printed circuit board assembly (PCBA); although small variations may trigger defects including solder bridges, tombstoning, or poor wetting.

At PCBBUY, engineering and production staff focuses on preventing defects as well as on proactive trouble shooting and high speed data-driven trouble shooting to maintain the best quality assembly on each assembly.

Learning the Defects of Common SMT

Before getting down to SMT defect troubleshooting, it is important to determine the most common problems that are experienced throughout the assembly process:

Solder Bridges:Solder bridges are formed as a result of too much solder paste being placed or as a result of misalignment of the components causing electrical shorts.

Tombstoning:Happens when one side of a chip component rises as a result of skewed solder reflow.

Various causes: Inadequate Solder Wetting - Results of oxidation, contamination or improper temperature profiles and results in low solder adhesion.

Solder Balling: Minute solder balls that are left on the PCB board as a result of overfluxing, or inappropriate reflow temperatures.

Component Misalignment :The pick-and-place operation may generate errors in the placement of components.

All these flaws may undermine the signal integrity, reliability of the components and the overall performance of the assembled PCB.

The PCBBUY Core of SMT Defects Troubleshooting

SMT troubleshooting at PCBBUY is not a reactive measure, it is part and parcel of our quality control approach. Automated optical inspection (AOI), X-ray inspection, and real-time monitoring of processes are used to identify and rectify the defects during early stages of production.

2.1. Root Cause Analysis (RCA)

When an SMT defect is found, the engineering team does a thorough root-cause analysis. Solder paste printing analysis, placement accuracy analysis, reflow oven profiling analysis, and stencil design analysis are also analysed so that the exact source of error can be identified.

2.2. Process Adjustments based on Data.

AOI and SPI (Solder Paste Inspection) process data are used to optimize the printer settings, stencil thickness, and reflow parameters, and hence the tendency to defects is alleviated.

2.3. Continuous Feedback Loop

The production line at PCBBUY is within a feedback-based quality loop whereby each batch is optimised on the performance of the previous batch. This is a continuous improvement model that helps in reducing defects and maintaining high yields.

State-of-the-Art SMT Technology that minimizes the defects

Our state of the art SMT production lines have Yamaha and JUKI high speed placement machines that can handle micro-components as small as 01005 packages. PCBBUY applies the following:

• Soldering of nitrogen in order to prevent oxidation.

• Automated stencil cleaning to ensure accuracy of deposition of paste.

• Storage under temperature control of moisture sensitive devices (MSDs).

• 3‑D solder paste inspection to provide early warnings of deposition problems.

These advanced systems significantly reduce both manual intervention and human error which are major concerns of long-term SMT defect troubleshooting effectiveness.

The Quality Assurance of SMT Assembly at PCBBUY

All SMT PCBAs that PCBBUY manufactures are in compliance with IPC A610 Class 2 quality standard that guarantees a reliable electrical and mechanical operation. The multi-layer inspection method comprises:

• Pre-reflow solder paste inspection (SPI).

• AOI after reflow to determine bridges, missing parts, or error of polarity.

• X-ray inspection of BGA, QFN and other hidden joint components.

Functional testing (FCT) to assure performance under realistic conditions.

This end-to-end inspection program ensures that the customers are being supplied with zero-defect PCBA assemblies even in fine-tuning medical, automotive, and communication designs.

The reason to use PCBBUY to perform reliable SMT Defect Troubleshooting is as follows.

The strength of PCBBUY is the automation of the processes and engineering expertise synthesis. The following are the advantages enjoyed by the clients:

• Mass-production and rapid prototyping.

• DFM (Design for Manufacturability) assistance in-house to prevent defects caused by design.

• Strict ESD measures and clean-room facilities of delicate parts.

24/7 support on engineering analysis and corrective action of defects.

With this holistic framework PCBBUY not only detects defects but also eliminates the causes of these defects- increasing reliability and decreasing time to market.

Summary

A successful SMT defect troubleshooting goes beyond correction of errors; it involves the establishment of a strong, smart manufacturing system. PCBBUY has decades of experience and long-term investments in automation and testing, which makes it a reliable partner of global clients who want to receive high-quality SMT assembly services. Regardless of creating medical devices, IoT modules, or high-density consumer electronics, PCBBUY makes sure that the products are of the highest quality in terms of precision and performance.

FAQ: SMT Defects Troubleshooting at PCBBUY

Q1: Which SMT defect PCBBUY experiences the most frequently?

A: Solder bridges and tombstoning are the most common defects, and they are immediately detected and rectified with AOI and reflow optimization.

Q2: What is the way that PCBBUY avoids SMT defects?

A: SPI, AOI, and X-ray systems combined with the expert engineering analysis allow identifying the possible defects and preventing them before they affect the production.

Q3: Does PCBBUY have the capability of small volume SMT assembly, but with high quality requirements?

A: Indeed. Each order, regardless of a prototype or a complete production, is based on IPC-A-610 Class 2 quality standards.

Q4: PCBBUY: Does it provide customized troubleshooting reports?

A: Yes; there is a comprehensive process feedback and inspection data that is provided per batch to make it fully transparent and continuously improve.

Industry Category