SMT Techniques in Modern PCB Assembly

By:PCBBUY 10/30/2025 17:22

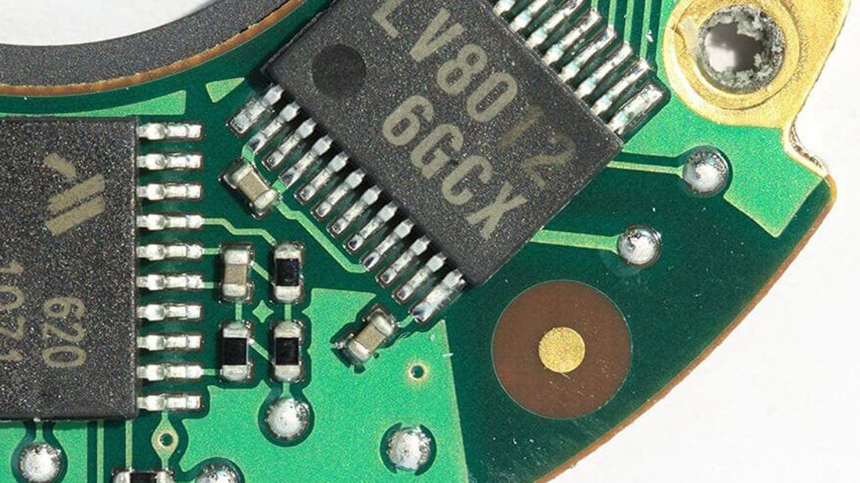

Surface Mount Technology (SMT) has become the foundation of modern electronic manufacturing. Compared with traditional through-hole assembly, SMT techniques allow components to be mounted directly onto the PCB surface, enabling higher component densities, smaller product sizes, and improved electrical performance. As products continue to demand compact structures and higher functionality, advanced SMT techniques are essential for achieving stable and long-lasting electronic assemblies.

At PCBBUY, we specialize in high-quality PCB fabrication and professional SMT assembly services. By applying state-of-the-art equipment, standardized process control, and IPC-certified workmanship, we ensure excellent reliability and durability across both prototypes and high-volume production.

1. Introduction to SMT Techniques

SMT techniques involve using precise solder paste deposition, automated pick-and-place systems, controlled reflow soldering profiles, and advanced inspection tools to ensure accurate and stable solder joints. These techniques significantly reduce assembly space, improve electrical performance, and support complex circuit designs with high integration.

However, the quality of SMT assembly depends greatly on manufacturing accuracy and controlled processes. PCBBUY continuously invests in production infrastructure and engineering expertise to guarantee stable SMT assembly quality for customers worldwide.

2. Key SMT Techniques in the Assembly Process

2.1 Solder Paste Printing SMT Techniques

The SMT process begins with solder paste application using a stainless steel stencil. Proper aspect ratio and stencil thickness control ensure ideal paste volume and prevent defects such as bridging or insufficient solder. PCBBUY utilizes fully automated paste printers with SPI (Solder Paste Inspection) to maintain consistent paste deposition layer by layer.

2.2 Pick-and-Place SMT Techniques

With high-speed placement equipment, components are positioned on the solder paste pad with precise alignment. PCBBUY’s SMT lines are capable of handling:

-

01005 / 0201 ultra-small components

-

0.4 mm pitch BGA, QFN, and CSP packages

-

High-speed CPU and memory modules

Pick-and-place positioning tolerance is controlled to micrometer levels to ensure accurate placement even for dense and fine-pitch boards.

2.3 Reflow Soldering SMT Techniques

Reflow soldering forms permanent solder joints under controlled temperature profiles. Temperature curve profiling is essential for different solder pastes (lead-free and leaded) and varying thermal capacities of PCB assemblies.

PCBBUY uses multi-zone intelligent reflow ovens, ensuring:

-

Stable heating and cooling gradients

-

Prevention of tombstoning, voiding, and cold solder joints

-

Compliance with RoHS lead-free standards

2.4 Inspection and Quality Verification SMT Techniques

To ensure the quality of finished assemblies:

-

SPI monitors solder paste thickness

-

AOI (Automated Optical Inspection) checks component position and polarity

-

X-ray Inspection is used for hidden joint packages such as BGA and QFN

3. Common Challenges in SMT Techniques and Solutions

|

Challenge |

Potential Cause |

PCBBUY Solution |

|

Bridging |

Excess solder paste |

Optimized stencil and SPI calibration |

|

Tombstoning |

Imbalanced heat distribution |

Controlled reflow curve |

|

Voids in BGA joints |

Incorrect profile or paste flux behavior |

X-ray evaluation and void ratio control |

|

Misalignment of micro-components |

Placement tolerance |

Ultra-precision pick-and-place with real-time correction |

4. Advanced SMT Techniques at PCBBUY

PCBBUY integrates advanced SMT techniques to support prototypes and mass production:

|

SMT Specification |

PCBBUY Capability |

|

Minimum Component Size |

01005 |

|

Minimum BGA Pitch |

0.4 mm |

|

Stencil Opening Accuracy |

±0.01 mm |

|

AOI Resolution |

10 μm |

|

X-ray Analysis |

BGA void ratio reporting |

|

Reflow Temperature Accuracy |

±1°C |

We also offer professional DFM (Design for Manufacturability) reviews to assist customers in optimizing their PCB layout before production.

5. Industry Applications Supported by SMT Techniques

PCBBUY provides SMT assembly in various industries, including:

-

Consumer electronics and wearable devices

-

Automotive electronics and EV control modules

-

Industrial automation systems

-

Medical monitoring equipment

-

Aerospace and defense-grade electronics

Each industry benefits from PCBBUY’s strict reliability standards and traceable quality control.

6. Why Choose PCBBUY for SMT Assembly

-

Professional engineering support and manufacturability guidance

-

Full process control from PCB fabrication to SMT assembly

-

IPC-A-610 certified workmanship

-

Flexible prototype and mass production capabilities

-

Fast global shipping and reliable product traceability

Conclusion

Advanced SMT techniques are essential for achieving reliable, compact, and high-performance electronic devices. By combining high-end equipment, strict quality control, and experienced engineering support, PCBBUY ensures excellent soldering quality and consistent production reliability.

If you are looking for stable and high-precision SMT assembly services, PCBBUY is ready to support your project from concept to final product.

FAQ – SMT Techniques in PCB Assembly

1. What are SMT techniques in PCB assembly?

SMT techniques refer to the processes used to mount electronic components directly onto the surface of a printed circuit board (PCB). These techniques include solder paste printing, automated pick-and-place, reflow soldering, and optical or X-ray inspection to ensure high accuracy and reliability.

2. Why are SMT techniques preferred over through-hole assembly?

SMT allows for smaller component sizes, higher circuit density, and faster automated assembly. This results in more compact device designs, reduced manufacturing cost, and improved electrical performance compared to traditional through-hole soldering.

3. What is the smallest component size supported by PCBBUY in SMT assembly?

PCBBUY supports 01005 ultra-miniature components and 0.4 mm pitch BGA devices, enabled by high-precision pick-and-place machines and advanced reflow profile control.

4. How does PCBBUY ensure soldering quality during SMT techniques?

PCBBUY uses SPI for solder paste inspection, AOI for placement verification, and X-ray inspection for hidden joints such as BGA and QFN. Each SMT process follows IPC-A-610 quality standards to ensure stable and reliable solder joints.

5. Can PCBBUY handle lead-free SMT assembly?

Yes. PCBBUY fully supports RoHS-compliant lead-free SMT assembly using certified lead-free solder paste and controlled reflow temperature profiling to maintain solder strength and long-term device reliability.

6. Does PCBBUY provide DFM (Design for Manufacturability) support for SMT techniques?

Yes. Before assembly, PCBBUY provides DFM feedback to help optimize pad design, stencil aperture ratios, and component layout, reducing risks of defects and improving production efficiency.

Industry Category