Solder Mask

By: 03/11/2021 09:30

Soldermask protects all the circuits on the outerlayers of the PCB, where we do not intend to attach components. But we also need to protect the exposed copper holes and pads where we plan to solder and mount the components. To protect those areas, and to provide a good solderable finish, we usually use metallic coatings, such as nickel, gold, tin/lead solder, silver and other final finishes designed just for PCB manufacturers.

This page will discuss some of the materials most commonly used to construct printed circuit boards, the characteristics of those materials.

What are Printed Circuit Boards Made Of?

Here are a few of the most popular materials used in the fabrication of printed circuit boards:

-

FR4 epoxy laminate and prepreg: FR4 is the most popular PCB substrate material in the world. FR4 laminates and prepreg are made from glass cloth, epoxy resin, and are usually the lowest cost PCB material available. It is especially popular for PCBs with lower layer counts – single, double sided into multilayered constructions generally less than 14 layers. Additionally, the base epoxy resin can be blended with additives that can significantly improve its thermal performance, electrical performance, and UL flame survival/rating – greatly improving its ability to be used in higher layer count builds, higher thermal stress applications, and greater electrical performance at a lower cost for high speed circuit designs. FR4 laminates and prepregs are very versatile, adaptable with widely accepted manufacturing techniques with predictable yields.

2.Polyimide laminates and prepreg: Polyimide laminates offer higher temperature performance than FR4 materials as well as a slight improvement in electrical performance properties. Polyimides materials cost more than FR4 but offer improved survivability in harsh and higher temperature environments. They also are more stable during thermal cycling, with less expansion characteristics, making them suitable for higher layer count constructions.

3.Teflon laminates and bonding plies: Teflon laminates and bonding materials offer excellent electrical properties, making them ideal for high speed circuitry applications. Teflon materials are more expensive than polyimide but provide designers with the high-speed capabilities that they need. Teflon materials can be coated onto glass fabric, but can also be manufactured as an unsupported film, or with special fillers and additives to improve mechanical properties. Manufacturing Teflon PCBs often requires a uniquely skilled workforce, specialized equipment and processing and an anticipation of lower manufacturing yields.

4.Flexible laminates: Flexible laminates are thin and provide the ability to fold the electronic design, without losing electrical continuity. They do not have glass fabric for support but are built on plastic film. They are equally effective folded into a device for a one-time flex to install application, as they are in dynamic flex, where the circuits will be folded continuously for the life of the device. Flexible laminates can be made from higher temperature materials like polyimide and LCP (liquid crystal polymer), or very low-cost materials such as polyester and PEN. Because the flexible laminates are so thin, manufacturing flexible circuits also can require a uniquely skilled workforce, specialized equipment and processing and an anticipation of lower manufacturing yields.

5.Others: There are many other laminates and bonding materials on the marketplace including BT, cyanate ester, ceramics, and blended systems that combine resins to get distinct electrical and/or mechanical performance characteristics. Because the volumes are so much lower than FR4, and the manufacturing can be much more difficult, they are usually considered expensive alternatives for PCB designs.

Careful laminate selection is important to ensure the PCB has the right electrical, dielectric, mechanical and thermal properties for the end application.

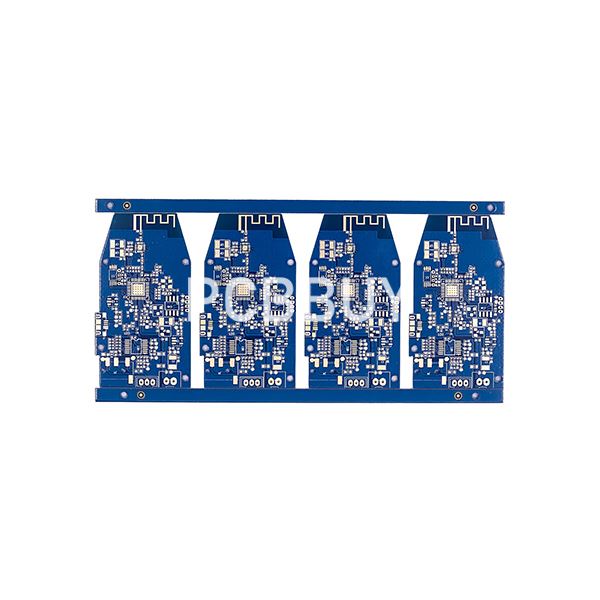

PCBBUY specializes in manufacturing flexible and rigid flex printed circuit boards. We carefully select materials to ensure that the PCBs we manufacture will offer ideal performance in critical applications and extreme environments.

Contact our team today to learn more about our PCB manufacturing services.

Industry Category