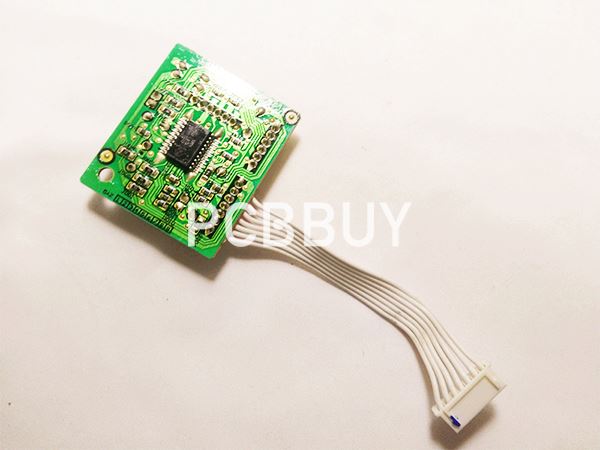

Soy Milk Machine Pcb

By: 03/13/2021 15:36

Soymilk machine, controlled by microcomputer, realizes the automatic preheating, beating, cooking and delayed cooking process. As the emphasis on health is gradually strengthened, in order to be clean and hygienic, many families have chosen to make their own soymilk, thereby driving the market of household microcomputer automatic soymilk machine. Soy milk has extremely high nutritional value and is a very ideal healthy food.

Soymilk machine type

1. By mode

Fully automatic soymilk machine: It is the most popular soymilk machine. It is very convenient to use. Just put the soybeans in the soymilk machine and press the switch for about 15 minutes to drink fresh soymilk.

Stone Mill Soymilk: Use traditional stone mill soymilk.

2. According to the polishing method

Soymilk machine: It is a professional soymilk machine. It is very convenient to use. Both dry and wet beans can be grinded, and there is no need to pour it out for cooking. You can choose this kind of soymilk if you drink it regularly.

Juicing and stirring compound soybean milk: the soybeans are crushed by stirring, and only the wet beans can be ground. After grinding, pour it out and cook in a pot. It can be used to squeeze juice.

3. Automatic separation refiner

Its characteristic is that while grinding the raw materials, the slurry and slag can be separated by itself in the machine body.

The machine has reasonable structure, beautiful appearance and convenient operation. It has small size, light weight, low voice, saves personnel, saves electricity, stable performance and reliable quality. I It is easy to clean and easy to move.

4. According to function

According to whether the soymilk machine can grind five-grain soymilk, dried/wet soymilk, cold drinks of fruits and vegetables, rice paste and corn juice, soymilk machines can almost complete these functions.

5. According to usage

Household soymilk machine: used in general households, the capacity of the soymilk machine can be selected according to the number of people in the family.

Commercial Soymilk Maker: Used in places with a relatively large number of people, such as hotels, fast food restaurants and other public places, the cost is more expensive than the household soymilk Maker, the structure is more complicated, and it has good stability.

6. With or without mesh

There are net-type soymilk machines: the market has existed for a long time, and the material of the net ranges from silk mesh to stainless steel mesh. Features: There are fine grinding of the net, delicate soybean milk, the use time of the motor is longer; it is not easy to clean.

Netless soybean milk machine: It came into being with the development of soybean milk machine technology. The stainless steel mesh was removed, and the chassis heating model was added under the new technology. Features: no net, soy milk is rough, the use time of the motor is short; easy to clean.

Soymilk machine composition structure

1. Cup

The cup is like a huge teacup with handles and spouts, and is mainly used to hold water or soy milk. Some cups are made of plastic and some are made of stainless steel, but they are made of stainless steel or polycarbonate that meets food hygiene standards. When purchasing the machine, it is better to choose the stainless steel cup body, mainly for easy cleaning. The "upper water level" line and the "lower water level" line are marked on the cup body to regulate the amount of water added to the cup body. The upper edge of the cup body just fits the lower cover of the machine head, so as to fix and support the machine head.

2. Machine head

The handpiece is the assembly of the soymilk machine. Except for the cup body, the remaining parts are fixed on the handpiece. The head casing is divided into an upper cover and a lower cover. The top cover has a handle, work indicator and power socket. The lower cover is used to install the main components. On the upper part of the lower cover (that is, inside the machine head), a computer board, transformer and beating motor are installed. The lower part protruding from the lower cover has an electric heater, a blade, a net cover, an anti-overflow electrode, a temperature sensor and an anti-dry electrode. It should be noted that the material of the lower cover also needs to comply with food hygiene standards.

3. Heater

Heating power 800 W, stainless steel material; there are heating tubes, heating plates, etc. according to the shape of the soybean milk machine, used to heat the soybean milk.

4. Temperature sensor

It is used to detect the water temperature in the cup during "preheating". When the water temperature reaches the set temperature of MCU (SH66P20A) (generally requires about 80 ℃), start the motor to start beating.

5. Anti-dry electrode

The electrode is not an independent component, but a stainless steel housing using a temperature sensor. The outer diameter of the shell is 6 mm, the effective length is 89 mm, and the length is much longer than the overflow prevention electrode. It is inserted into the bottom of the cup body. When the water level of the cup is normal, the lower end of the anti-dry electrode should be immersed in water. When the water level in the cup is low or no water, or the machine head is lifted, and the lower end of the anti-dry electrode is removed from the water surface, the MCU (microcontroller) detects this state through the anti-dry electrode to ensure safety. Soymilk machines will be prohibited from working.

6. Blade

The shape of the blade is exactly like the propeller of the ship, and it is made of high hardness stainless steel, which is used to crush the beans. There are S type, X type, I type and so on.

7. Net cover

Used to hold beans and filter soy milk. In actual work, the mesh cover is fastened to the lower cover of the machine head by fastening the oblique flute. When cleaning, you will find that the mesh cover and the lower cover of the machine head are too tight after being heated. Therefore, when removing the mesh cover, you should first cool it with cold water to avoid scratching your hand or damaging the mesh cover with too much force.

In particular, cleaning the net cover is relatively time-consuming and often makes users feel too hard. This problem has attracted the attention of various manufacturers. After technological innovation, Jiuyang Company has achieved a major breakthrough in the improvement of the net cover. The Lafarre net applying Jiuyang's patented diversion technology is matched with the "X-type cyclone blade". After tens of thousands of full-cycle fine refining, it not only greatly It improves the nutritional quality of soy milk and at the same time makes the cleaning of the grille simple and easy.

8. Anti-overflow electrode

It is used to detect the boiling of soybean milk and prevent the overflow of soybean milk. Its outer diameter is 5 mm and its effective length is 15 mm, which is above the cup. In order to ensure the normal operation of the anti-overflow electrode, it must be cleaned in time, and the soybean milk should not be too thin, otherwise, the anti-overflow electrode will lose its protective effect and cause an overflow cup.

Soymilk working principle

Circuit characteristics

The fully automated processes such as preheating, beating, and boiling of the general soybean milk machine are controlled by the MCU (Single Chip Microcomputer) related pins, driven by the corresponding transistors, and then implemented by the relay group composed of multiple relays to implement circuit conversion. As long as you master this basic rule, you can conduct circuit checks on all types of soymilk machines to eliminate various types of faults. However, some soymilk models have a little problem with the production of the circuit board. It presses the component number under the component, so only the component can be seen on the circuit board, but the component number cannot be seen. inconvenient.

work process

Add an appropriate amount of water, either warm or cold water. After powering on, start the "pulping" function, the electric heating tube begins to heat, and the water temperature reaches the set temperature after 25 minutes. In the pre-beating stage, when the water temperature reaches the set temperature, the motor starts to work for the first pre-beating, and then continues to heat to reach the beating temperature after touching the anti-overflow electrode.

In the beating/heating stage, the beating and Heating so that the soybeans are completely crushed, the soybean milk is initially boiled, and boiled. After the soybean milk is boiled, it enters the boiling stage, and the heating tube repeatedly heats the gap, so that the soybean milk is fully cooked and completely emulsified.

Industry Category