Stretchable PCB technology

By:PCBBUY 07/23/2021 17:17

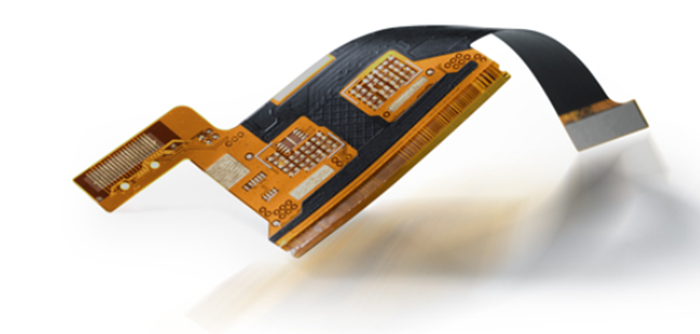

Even though stretchable printed circuit board technology employs usual production and subsequent assembly steps, the laminate is Polyimide or Polyurethane. Polyimide or Polyurethane comes with the advantage of producing stretchable printed circuit boards with significantly low investment costs. To assemble the substrate's components quickly, plenty of manufacturers employ one of the below methods.

Manufacturers mainly reinforce the laminate locally by using a special coating or an interposer. However, the ultimate method is to employ a technology known as Stretch-Rigid. As opposed to connecting two rigid boards by a flexible PCB such as in Rigid-Flex construction, Stretch-Rigid works better and efficiently.

In this passage, we will focus on the stretchable PCB and the application of it. Please check and read the content we prepare to learn more information.

What are the advantages of stretchable PCB?

Stretchable PCBs are explicitly designed to save space while improving flexibility to meet smaller and mounting designs of high density.

Additionally, it also helps in reducing the process of assembly while enhancing reliability at the same time. In short, stretchable PCBs are the only solution that ensures miniaturization and the movement of electronic devices.

There are several advantages associated with stretchable printed circuit boards worth mentioning. For instance, stretchable PCBs can be twisted, bent, and moved without the risk of damaging the conductor. Additionally, special packaged sizes and several outlines get permitted with stretchable printed circuit boards.

That is not all. Stretchable PCBs provide outstanding electrical performance. They come with a low dielectric constant that gives room for the electrical transmission of signal and impressive thermal properties that make cooling very easy. Better yet, stretchable PCBs can operate well under high temperatures, unlike rigid PCBs.

Stretchable PCBs provide higher assembly output and reliability due to reduced internal connections hardware. Furthermore, there is little error during assembly since this is a PCBs designed or manufactured for one-way assembly. Stretchable boards can alter their positions with ease while remaining tethered electrically to each other all the time.

Briefly speaking, some of the reasons to use stretchable PCBs as opposed to rigid ones include:

• Reduced weight and space

• They meet changing flexing requirements

• Flexing for ease of service and installation

• Increase repeatability and reliability

• Excellent thermal management

• Reduce the costs of assembly

• Does away with connectors

• They provide uniform electrical characteristics for circuitry that require high speeds

What is the working principle of stretchable PCB?

While the thermoplastic Polyurethane used by manufacturers as substrate meant for stretchable PCBs can stretch easily, copper traces inhibits it from spreading. The reason for this is because copper is not malleable enough for such purposes.

Manufacturers use their confidential lay-up techniques and specialized press for bonding RA copper foil or standard ED on the Polyurethane substrate. Upon completing this step, they then use normal subtractive wet-etching printed circuit board steps to fabricate the stretchable circuits.

Since adding several layers of Polyurethane substrate and adhesive minimizes stretchability, most stretchable PCBs are double-sided or four layers at the most. Manufacturers apply polyurethane solder masks to finished PCBs to maintain a uniform elastomer design.

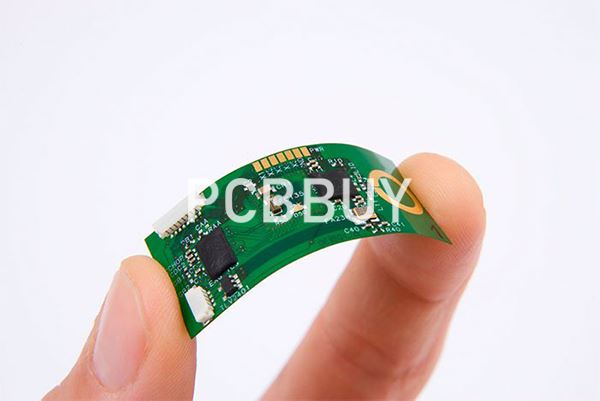

The assembly of stretchable PCBs employs the normal off-the-shelf surface mounting components soldered on the copper tracks. Since the parts are rigid, the places where the elements get positioned is impossible to stretch. In short, the concept of stretchable PCBs is some small islands of severe nature that holds few SMD components. These SMD components are interconnected using some conductive paper foil on stretchable substrates.

To ensure that traces of copper found on the substrate flex or bend without damage, designers give a horseshoe shape to the copper traces. After that, the horseshoe shapes are placed alternatively at 180° to allow them to meander along a path that would have been taken by straight marks. While other different ways, such as triangular shapes, can stretch, they exhibit high-stress levels and bring about lower reliability.

What are the applications of stretchable PCB?

Mainly, applications that call for a stretched printed circuit board use are on bent or non-flat surfaces. These come in as some of the significant users of stretchable PCBs. It is evident that such applications are on the increase, and so are stretchable PCBs. A traditional rigid PCB can’t be comfortable placed or used on integrated surfaces such as implanted devices or wearables.

Devices and components used in smart textiles, biomedical applications, sports, safety, and leisure are often irregular in shape. With such irregular shapes, a printed circuit board has to follow the form required for efficient integration. While it’s possible to develop a flexible circuit shape like a cylinder or cone, stretchable circuits can easily fit into any surface.

Having said, stretchable PCBs find use in plenty of applications from consumer clothing to complex positioning and medical applications, among others. For example, stretchable PCBs can be placed inside a shoe's sole to measure pressure using embedded sensors. They do so by collecting user data based on free movement.

Stretchable PCBs are also placed inside bandages as they contain pressure sensors that can efficiently measure the contact pressure. The ability to measure contact pressure is a vital factor in handy, especially when handling open wounds.

Industry Category