Thermal Stress Reliability of Multilayer PCB

By:PCBBUY 01/23/2026 17:53

1. Introduction

Thermal stress reliability of multilayer PCB has become a critical concern as electronic devices continue to operate at higher power densities and wider temperature ranges. From industrial control systems to automotive electronics, multilayer PCBs are repeatedly exposed to thermal cycling during both assembly and field operation.

Thermal stress, if not properly controlled, can lead to latent failures such as via cracking, delamination, and copper fatigue. These failures often appear long after product shipment, making thermal reliability a key indicator of PCB manufacturing quality rather than simple electrical performance.

This article explains the mechanisms behind thermal stress in multilayer PCBs and highlights how advanced manufacturing processes help improve long-term reliability.

2. What Is Thermal Stress in Multilayer PCB?

Thermal stress refers to the mechanical stress generated inside a PCB structure due to temperature changes. In multilayer PCBs, different materials—copper, resin, and glass fiber—expand and contract at different rates when heated or cooled.

Because these materials are bonded together, mismatched expansion creates internal stress, especially during rapid temperature transitions such as reflow soldering or thermal cycling in operation.

3. Common Thermal Stress Failure Modes

Thermal stress can trigger several reliability issues in multilayer PCBs, particularly in high-layer-count designs.

|

Failure Mode |

Description |

Typical Impact |

|

Via barrel cracking |

Cracks form in plated through holes due to Z-axis expansion |

Intermittent or open circuits |

|

Delamination |

Separation between copper and dielectric layers |

Signal integrity loss, moisture ingress |

|

Copper fatigue |

Repeated expansion causes copper cracking |

Reduced current-carrying capability |

|

Pad lifting |

Pads detach from inner layers |

Assembly and repair failures |

These failures are often cumulative, meaning they worsen with repeated thermal cycles.

4. Material Properties Affecting Thermal Stress Reliability

Material selection plays a foundational role in thermal stress reliability of multilayer PCB.

Key material factors include:

-

Coefficient of Thermal Expansion (CTE): Lower Z-axis CTE reduces via stress

-

Glass Transition Temperature (Tg): Higher Tg materials maintain mechanical stability at elevated temperatures

-

Resin system: High-performance resin improves bonding strength

-

Glass fabric structure: Controls dimensional stability and resin distribution

High-Tg and low-CTE materials are commonly used in PCBs designed for demanding thermal environments.

5. Manufacturing Process Factors Influencing Thermal Stress

Beyond materials, manufacturing process control directly determines how well a PCB resists thermal stress.

Critical process factors include:

-

Lamination pressure and temperature control to ensure uniform bonding

-

Resin flow management to avoid resin starvation or excessive squeeze-out

-

Balanced stackup design to minimize internal stress concentration

-

Controlled drilling parameters to prevent microcracks before plating

Poor control at any of these stages can significantly reduce thermal reliability, even when premium materials are used.

6. Thermal Stress During Assembly Processes

Assembly processes are often the most severe thermal events a PCB experiences.

Typical stress sources include:

-

Lead-free reflow soldering with peak temperatures above 245°C

-

Multiple reflow cycles for double-sided or complex assemblies

-

Localized heating during rework

Multilayer PCBs must be manufactured to tolerate these short-term but intense thermal shocks without structural degradation.

7. Testing and Inspection for Thermal Stress Reliability

To verify thermal stress reliability, manufacturers apply a combination of destructive and non-destructive testing methods.

|

Test Method |

Purpose |

|

Thermal cycling test |

Simulates long-term temperature variation |

|

Micro-section analysis |

Detects via cracks and layer separation |

|

Cross-sectional inspection |

Verifies plating thickness and bonding |

|

Electrical continuity testing |

Confirms circuit integrity after cycling |

These tests help ensure that latent defects are identified before shipment.

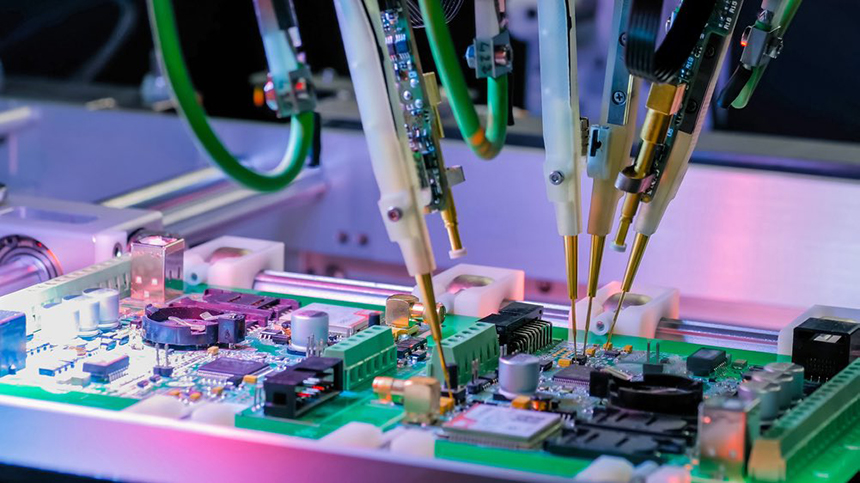

8. Manufacturing Techniques to Improve Thermal Stress Reliability

Advanced PCB manufacturers apply multiple techniques to improve thermal stress resistance:

-

Optimized lamination profiles for high-layer-count boards

-

Uniform via plating thickness to strengthen Z-axis structures

-

Copper balance control to reduce localized stress

-

Tight process monitoring and SPC controls

Consistent process execution is essential to achieving repeatable reliability results.

9. Design Guidelines to Reduce Thermal Stress

Thermal stress reliability is strongest when design and manufacturing work together.

Recommended design practices include:

-

Symmetrical multilayer stackups

-

Adequate annular ring and via aspect ratio control

-

Balanced copper distribution across layers

-

Early DFM communication with the PCB manufacturer

These measures significantly reduce stress accumulation during thermal cycling.

10. PCBBUY’s Capability in Thermal Stress Reliability Control

PCBBUY applies strict material qualification, controlled lamination processes, and comprehensive reliability testing to ensure multilayer PCB thermal stress performance.

With experience in high-layer-count and high-reliability PCB manufacturing, PCBBUY supports applications requiring stable performance under repeated thermal exposure.

11. Applications Requiring High Thermal Stress Reliability

-

Industrial automation equipment

-

Automotive electronic control units

-

Power management and energy systems

-

Communication and networking hardware

In these applications, thermal reliability directly impacts product lifespan and safety.

12. Conclusion

Thermal stress reliability of multilayer PCB is determined by a combination of material properties, manufacturing process control, and thoughtful design. As operating temperatures rise and product lifecycles lengthen, thermal reliability is no longer optional—it is a core quality requirement.

Choosing a PCB manufacturer with proven thermal stress control capability is essential for long-term product success.

FAQ

Q1: What causes thermal stress in multilayer PCB?

Thermal stress is caused by mismatched thermal expansion between copper, resin, and glass fiber when temperatures change during assembly or operation.

Q2: How does thermal cycling affect PCB reliability?

Repeated thermal cycling can gradually weaken vias, copper traces, and interlayer bonds, eventually leading to cracks or delamination.

Q3: Can thermal stress cause via failure in multilayer PCB?

Yes. Via barrel cracking is one of the most common failures caused by Z-axis expansion under thermal stress.

Q4: Which materials improve thermal stress reliability?

High-Tg, low-CTE laminate systems with strong resin bonding properties significantly improve thermal stress resistance.

Q5: How does PCB manufacturing reduce thermal stress risk?

Through controlled lamination, balanced stackup design, uniform via plating, and rigorous reliability testing.

Industry Category