Tokyo Olympic: Use PCBs to make medals

By:PCBBUY 07/29/2021 14:24

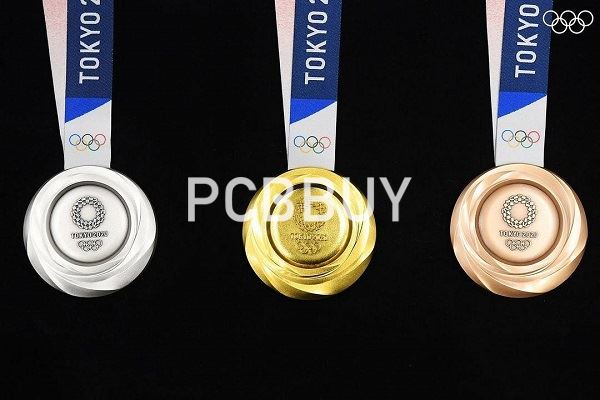

The Tokyo Olympic Games have begun, and there are lots of interesting episodes like this. But in this passage, we are going to introduce you another interesting episode: How are Olympic medals made? Quite unexpectedly, they are made from e-waste.

The medals were made from 80,000 tons of electronic waste, including 78,985 tons of small appliances and 6.21 million old mobile phones. About 32 kg of pure gold, 3,500 kg of pure silver and 2,200 kg of copper are extracted from it. Among them, a very considerable amount of gold, silver, copper and other materials were extracted from PCB.

It is amazing! In the future, athletes will win metal MEDALS extracted from mobile phones used by millions of Japanese.

Actually the gold, silver and copper in mobile phones come mainly from PCB boards. Why do PCBS need these precious metals?

Gold plating is mainly for oxidation resistance. But there is a little amount of gold in the circuit board or chip. The gold of the circuit board is crushed first, then chemical immersion, and then replacement. In the extraction of gold, there are a number of other additional products, such as copper, silver and so on.

The precious metal has produced electronic waste recycling (so as components recycling). Plenty of circuit boards need to be gold-plated, and some chips contain traces of gold. However, these chemicals will cause serious pollution to the environment! It is possible that the cost of treating the wastewater may exceed the cost of the extracted metal.

PCBS contain a lot of precious metals. The average smart phone contains 0.05g of gold, 0.26g of silver and 12.6g of copper, while a laptop contains 10 times more gold than a mobile phone.

Why do PCBs contain precious metals?

As the support body of electronic components, PCB’s surface needs soldering components. This requires a portion of the copper layer to be exposed for soldering. These exposed layers of copper are called pads. Pads are usually small, rectangular or round. So with the paint, the only exposure to the air is the copper on the pads.

The exposed pads on the PCB, with the copper layer directly exposed. This part needs to be protected from oxidation. Copper in PCB is easily oxidized. If the copper on the pad is oxidized, it is not only difficult to solder, but also increases the resistivity, seriously affecting the final product performance. So, cover the pads with the inert metal gold or silver, or cover copper with a special chemical film to prevent contact with the air. Prevent oxidation and protect the pad to ensure a good yield in the next soldering process.

Does the material of PCB contain metal?

Take PCB copper-clad boards as an example:

1. Copper clad PCB

Copper clad board is made of glass fiber cloth or other reinforced material dipped in resin, one or both sides covered with copper foil and hot pressed. The conductor used in PCB is generally made of thin foil refined copper, which is copper foil in the narrow sense.

Take glass fiber cloth based copper clad board as an example, its main raw materials are copper foil, glass fiber cloth, epoxy resin, accounting for about 32%, 29% and 26% of the product cost respectively.

2. Immersion gold PCB

In immersion gold PCB, because golden words will have direct contact with copper electron diffusion of physical reaction (potential), so must first electroplating a layer of nickel as a barrier layer, and then put the gold plating to the top of the nickel, so we usually called electric plating, its actual name should be called gold plating nickel.

The difference between hard gold and soft gold is the composition of the last layer of gold plated. When gold-plated, you can choose to electroplate pure gold or alloy. Because the hardness of pure gold is soft, it is also called "soft gold". Because "gold" can form a good alloy with "aluminum", COB will specifically require the thickness of this layer of pure gold when making aluminum wire. In addition, if you choose electroplated nickel or gold-cobalt alloy, because the alloy will be harder than pure gold, so it is called "hard gold."

Gold layer is widely used in the circuit board components of the solder pad, golden finger, connector and other positions. We use the most extensive the main board of mobile phone PCB is mostly gold-plated board, immersion gold board, computer motherboard, audio and small digital circuit board are generally not gold-plated board.

Industry Category