Understand PCB Prepreg VS Core with Material Differences and Manufacturing Capability

By:PCBBUY 01/09/2026 15:12

Introduction

In multilayer PCB manufacturing, material selection directly affects electrical performance, mechanical stability, and production reliability. Among the most critical materials are PCB prepreg and PCB core, both of which play distinct roles in multilayer stackup design.

Understanding the difference between PCB prepreg vs core helps engineers evaluate not only PCB design feasibility, but also a manufacturer’s true processing capability.

What Is PCB Core Material?

PCB core is a fully cured laminate material with copper foil bonded on both sides. It serves as the structural backbone of a multilayer PCB and defines the position of inner signal layers.

Core materials are typically supplied with controlled thickness and copper weight, providing dimensional stability during fabrication.

What Is PCB Prepreg?

PCB prepreg is a fiberglass fabric impregnated with partially cured resin. Unlike core material, prepreg does not include copper foil and functions primarily as a bonding and insulating layer during lamination. When heat and pressure are applied, the resin in prepreg flows, fills gaps, and cures to bond adjacent layers together.

PCB Prepreg VS Core: Functional Differences

The fundamental differences between prepreg and core become clear when comparing their roles in multilayer PCB manufacturing.

|

Aspect |

PCB Core |

PCB Prepreg |

|

Material State |

Fully cured |

Partially cured |

|

Copper Foil |

Copper on both sides |

No copper |

|

Primary Function |

Structural support |

Bonding and insulation |

|

Thickness Control |

Fixed and precise |

Variable after lamination |

|

Resin Flow |

Minimal |

Active during lamination |

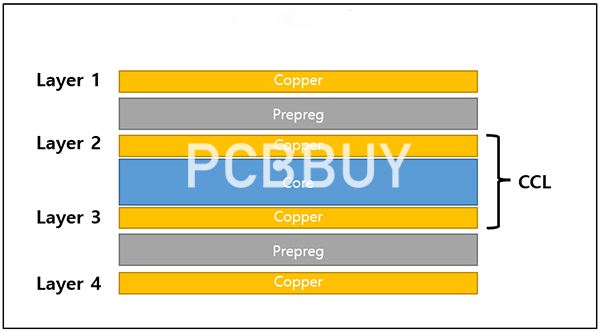

Role in Multilayer PCB Stackup Design

In a multilayer PCB stackup, core materials define where signal layers are located, while prepreg determines the spacing between layers.

This combination directly impacts:

-

Controlled impedance design

-

Signal integrity and crosstalk

-

Power and ground plane separation

-

Stackup symmetry and mechanical balance

Accurate selection of prepreg and core is essential for predictable electrical performance.

Lamination Process: Prepreg VS Core Behavior

During lamination, prepreg and core behave very differently.

-

Core material remains dimensionally stable under heat and pressure

-

Prepreg resin softens, flows, fills voids, and cures to form strong interlayer bonds

Improper resin flow control can result in voids, delamination, or thickness inconsistency, especially in high-layer-count PCBs.

Manufacturing Challenges Related to Prepreg and Core

Processing prepreg and core materials introduces several manufacturing challenges:

-

Controlling resin flow to avoid voids and squeeze-out

-

Managing thickness variation after lamination

-

Ensuring material compatibility between prepreg and core

-

Maintaining layer-to-layer registration accuracy

These challenges increase as PCB layer count and design density increase.

Electrical Performance Implications

Material properties of prepreg and core influence key electrical parameters:

-

Dielectric constant (Dk) consistency

-

Impedance control accuracy

-

Signal loss and propagation behavior

High-speed and impedance-controlled designs require tight coordination between stackup design and lamination process control.

Manufacturing Capability Reflected by Prepreg and Core Handling

The ability to consistently process prepreg and core materials reflects a PCB manufacturer’s technical maturity.

Key indicators of strong manufacturing capability include:

-

Qualified material sourcing and incoming inspection

-

Stable lamination pressure and temperature control

-

Engineering-driven stackup optimization

-

Experience with multilayer and high-reliability PCBs

PCBBUY’s Approach to PCB Prepreg and Core Processing

PCBBUY applies controlled material selection and lamination processes to ensure reliable multilayer PCB production. By aligning prepreg resin systems with core materials and optimizing lamination parameters, PCBBUY supports consistent electrical and mechanical performance.

Manufacturing capabilities include:

-

Support for standard and high-Tg material systems

-

Multilayer lamination expertise

-

Engineering assistance for stackup and impedance planning

-

Export-oriented quality control standards

Design Considerations for Engineers

To improve manufacturability and reliability, designers should:

-

Clearly specify prepreg and core requirements

-

Consider thickness tolerance after lamination

-

Coordinate impedance requirements with material selection

-

Consult manufacturers early for stackup validation

Early collaboration reduces production risk and redesign cycles.

Typical Applications Requiring Precise Prepreg and Core Control

Accurate prepreg and core management is essential for:

-

High-speed digital PCBs

-

Multilayer industrial electronics

-

High-density interconnect (HDI) designs

-

Export-grade and high-reliability PCBs

Conclusion

The comparison between PCB prepreg vs core highlights their distinct roles in multilayer PCB manufacturing. While core provides structural stability and defines signal layers, prepreg enables bonding and electrical insulation through controlled resin flow.

Manufacturers with strong process control and material expertise can reliably handle complex stackups and deliver consistent PCB quality. This capability is critical for advanced multilayer PCB production.

FAQ

What is the main difference between PCB prepreg and core?

PCB core is fully cured laminate with copper foil, while prepreg is partially cured resin material used for bonding layers during lamination.

Why is prepreg important in multilayer PCB manufacturing?

Prepreg provides insulation and bonding between layers, and its resin flow behavior directly affects lamination quality.

Does prepreg thickness affect impedance control?

Yes. Prepreg thickness after lamination determines layer spacing, which directly influences controlled impedance.

Can improper prepreg selection cause PCB defects?

Yes. Poor prepreg selection or resin flow control can lead to voids, delamination, and thickness inconsistency.

Can PCBBUY support custom stackup designs using prepreg and core?

Yes. PCBBUY provides engineering support for custom stackup design using appropriate prepreg and core combinations.

Industry Category