Understanding Counterbore Tolerance in PCB Manufacturing

By:PCBBUY 07/15/2025 15:23

Why Counterbore Tolerance Is Crucial for High-Reliability PCBs

In modern high-density PCB manufacturing, mechanical precision is just as critical as electrical performance. Among the key mechanical features, counterbore tolerance directly impacts component mounting, connector engagement, and overall product durability. At PCBBUY, we offer industry-leading capabilities in both T-shaped and V-shaped counterbores with precise dimensional control, supporting a wide range of product applications from consumer electronics to automotive and aerospace systems.

What Is Counterbore Tolerance?

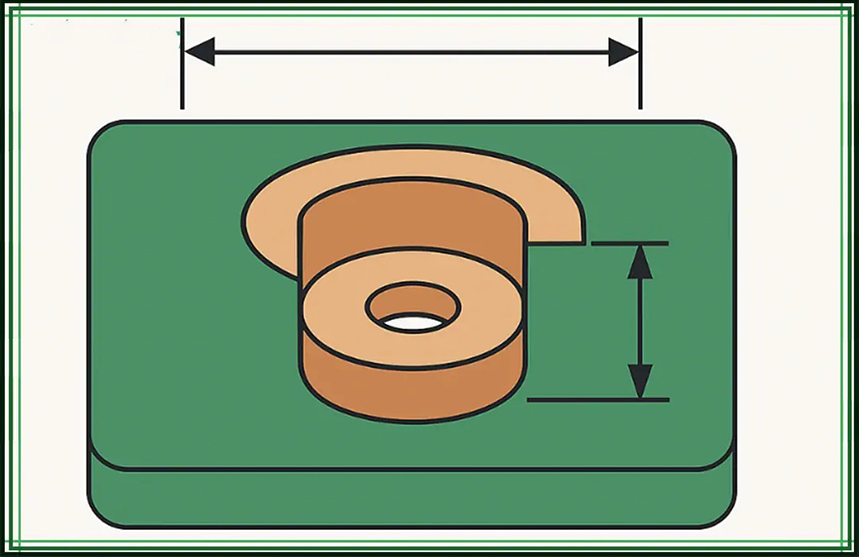

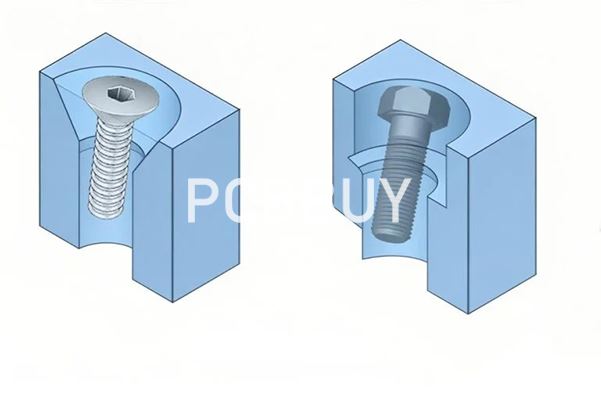

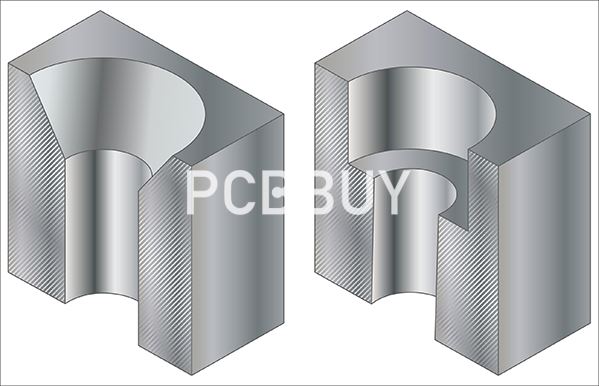

A counterbore is a cylindrical flat-bottomed hole that enlarges another hole, typically to allow for the head of a screw or fastener to sit flush with or below the surface. In PCB manufacturing, counterbores are often used in mechanical structures or for mounting requirements.

Counterbore tolerance refers to the acceptable variation in dimensions such as depth, diameter, and concentricity. Tight tolerance ensures precise alignment, proper mating with mechanical components, and structural stability.

PCBBUY’s Standard Counterbore Tolerance Capabilities

At PCBBUY, we provide two primary counterbore types with strict dimensional controls:

● T-Shaped Counterbore

-

Minimum Depth: ≥0.2 mm

-

Hole Size: ≥2 mm

-

PTH Hole Tolerance: ±0.2 mm

-

NPTH Hole Tolerance: ±0.15 mm

-

Remarks: Deeper boreholes can be customized based on client needs.

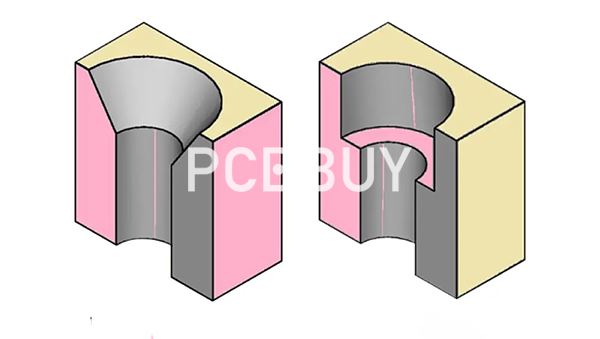

● V-Shaped Counterbore (Horn Hole)

-

Angle: 90° normal

-

Hole Size Range: 4–20 mm

-

PTH Hole Tolerance: ±0.2 mm

-

NPTH Hole Tolerance: ±0.15 mm

-

Remarks: Custom horn hole structures available upon request.

These parameters meet most industrial design specifications, while offering flexibility for customization during complex product development cycles.

Why Tight Counterbore Tolerance Matters

Accurate counterbore dimensions are vital to ensure:

-

Smooth mechanical integration

-

Reduced component stress during assembly

-

Proper fit for connectors or mechanical fasteners

-

Avoidance of misalignment that can affect signal or power flow

In applications such as automotive electronics, industrial control systems, and embedded systems, even minor mechanical deviation can result in performance degradation or failure.

Advanced Drilling and Inspection Processes at PCBBUY

To guarantee strict adherence to tolerance specifications, PCBBUY utilizes high-precision manufacturing techniques:

-

CNC-Driven Drilling: Ensures accurate depth and diameter

-

Layer-Registered Drilling: Prevents misalignment in multilayer boards

-

X-Ray Targeting for Inner Layers: Enables precision even in complex stackups

-

Automated Optical Inspection (AOI): Validates dimensions and detects defects early

-

CAM Engineering Review: Pre-production assessment to verify counterbore compatibility

All counterbores are measured and verified using precision metrology equipment before proceeding to the next manufacturing stage.

Flexible Customization for Non-Standard Counterbore Tolerance

PCBBUY understands that innovation sometimes requires going beyond standard parameters. For this reason, we offer:

-

Deeper borehole customization for structural designs

-

Wider angle or dual-step counterbores

-

Non-standard mechanical cutouts and pocketing

-

Tighter or looser tolerances per project requirement

Customers can submit detailed drawings, and our engineering team will evaluate manufacturability through a fast Design for Manufacturability (DFM) process.

Applications Where Counterbore Tolerance Is Essential

|

Industry |

Application |

Tolerance Impact |

|

Automotive |

Dashboard control modules |

High vibration resistance |

|

Consumer Devices |

Smartwatch enclosures |

Precision screw fitment |

|

Aerospace |

Avionics interfaces |

Structural integrity |

|

Medical Devices |

Implantable electronics |

Reliable mechanical assembly |

|

Industrial |

Robotics arms |

High-precision positioning |

Why Choose PCBBUY for Counterbore Tolerance-Sensitive PCBs?

PCBBUY has over a decade of experience delivering mechanically critical PCBs to global clients. We ensure:

-

Certified quality systems (ISO/UL/ROHS compliant)

-

Multistage tolerance validation during drilling, plating, and final inspection

-

Fast lead times with custom requests supported

-

End-to-end support from file preparation to final delivery

FAQs About Counterbore Tolerance at PCBBUY

Q1: What’s the difference between PTH and NPTH counterbore tolerance?

A: PTH (Plated Through Hole) has slightly wider tolerance due to plating variability (±0.2 mm), while NPTH (Non-Plated Through Hole) can achieve tighter control (±0.15 mm).

Q2: Can PCBBUY handle deep or double-step counterbores?

A: Yes, we support deep borehole structures and customized layered cavities based on customer requirements.

Q3: Do I need to specify counterbore in my Gerber files?

A: Yes. Provide detailed layer drawings or mechanical files (.dxf or .pdf) indicating the position, depth, and tolerance.

Q4: What happens if my design is out of PCBBUY’s standard tolerance range?

A: Our engineers will evaluate your design and provide feasible alternatives or a quote for customized tooling.

Q5: Is there a minimum order requirement for counterbore PCBs?

A: No. We support both prototyping and mass production with counterbore requirements.

Conclusion

Whether your project demands standard counterbores or custom mechanical cavities with tight tolerances, PCBBUY has the capability, technology, and expertise to deliver. Reach out today for a free DFM review and start building precision-driven, mechanically optimized PCBs with us.

👉 Contact us for a quote or upload your PCB files to get started.

Industry Category