Understanding Counterboring Services in PCB Manufacturing

By:PCBBUY 11/24/2025 15:50

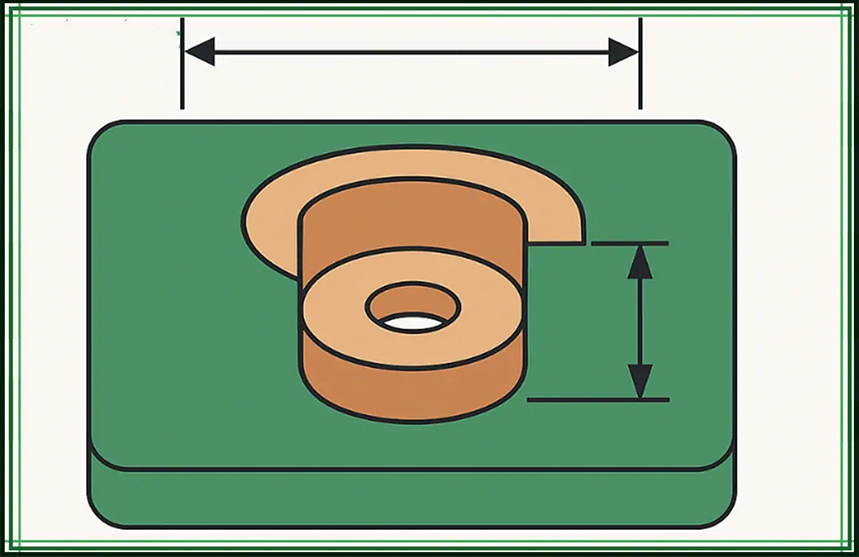

Counterboring is a precision mechanical operation applied to PCBs to create a flat-bottom enlargement above a drilled hole. It is primarily used for fastener mounting, ensuring that screw heads fit below the board surface without interfering with component placement or enclosure assembly.

In this article, we’ll walk you through what counterboring is, how it works, and why PCBBUY has become a trusted partner for customers needing high-precision mechanical machining in PCB production.

1. What Are Counterboring Services?

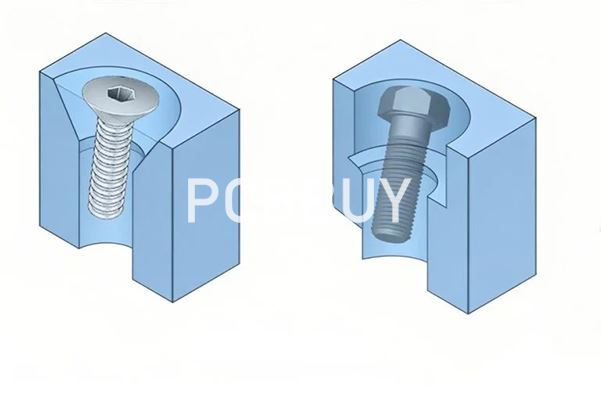

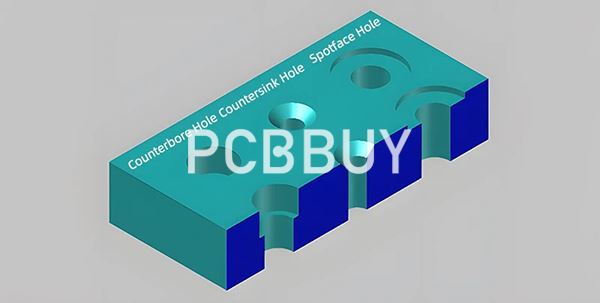

A counterbore is a cylindrical flat-bottom enlargement at the top of a hole. In PCB manufacturing, it allows fasteners—especially screws with cylindrical heads—to sit below or flush with the PCB surface.

While a countersink has a conical shape, a counterbore is always flat-bottomed, making it ideal for hardware that requires stable mounting.

You’ll typically find counterbores used in:

-

PCBs fixed directly to metal housings

-

Products requiring strong mechanical fastening

-

Power boards and thick industrial PCBs

-

Aluminum PCBs (MCPCB) with structural mounting holes

2. How Counterboring Works in PCB Production

2.1 Common PCB Types That Require Counterbores

Not every PCB needs a counterbore, but they are essential when:

-

The screw head must sit perfectly flush

-

The PCB must attach to a rigid chassis

-

Thick laminates require deep fastener seating

-

Components need clearance on the PCB top layer

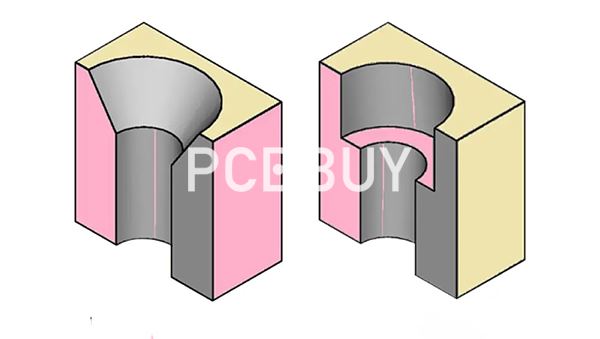

2.2 Types of Counterbores

PCBBUY supports:

-

NPTH counterbores (most common)

-

PTH counterbores (special requirements)

-

Deep counterbores for thick boards

-

Counterbores on aluminum-based PCBs

Each category has specific machining rules and tolerance limits, which PCBBUY’s engineering team reviews before production.

3. PCBBUY’s Counterboring Services and Precision Capabilities

At PCBBUY, counterboring is performed using high-accuracy CNC milling systems equipped with Z-axis power-feed, ensuring stable depth control and smooth internal surfaces.

Our capabilities include:

-

±0.05 mm depth tolerance

-

Concentricity control for counterbore + through-hole alignment

-

Support for FR4, aluminum substrates, copper boards, and hybrid laminates

-

Minimum counterbore diameter around 2.0 mm (tooling dependent)

-

Smooth edge finish with burr control

PCBBUY’s team reviews all mechanical layers and drill tables during CAM analysis to ensure your design meets manufacturable guidelines.

4. PCBBUY’s Counterboring Workflow

-

Gerber/CAD data review

-

DFM check to verify depth, diameter, plating and layer clearance

-

CNC tool path programming

-

Z-axis precision milling

-

Dimensional inspection using 2D/3D metrology tools

-

Final QC before shipment

Every counterbored hole is checked for depth accuracy, flatness, and concentricity.

5. Design Tips: PCB Counterbore Guidelines for Engineers

To avoid costly redesigns, PCBBUY recommends including the following:

5.1 Provide Complete Data

-

Counterbore diameter

-

Counterbore depth

-

Through-hole size

-

Plating requirements (PTH/NPTH)

-

Clear markings in the mechanical layer

5.2 Follow Minimum Design Rules

-

Recommended min. diameter: 2.0–2.5 mm

-

Depth should not exceed 40–50% of PCB thickness unless approved

-

Keep enough distance from PCB edges

5.3 Common Mistakes to Avoid

-

Missing depth values

-

No plating instructions

-

Counterbores too close to copper or internal layers

-

Over-deep milling on thin boards

PCBBUY’s engineering team performs a free DFM review to catch these issues before production.

6. Why PCBBUY Is a Reliable Partner for Counterboring Services

Customers choose PCBBUY because we provide:

-

Advanced CNC routing & milling systems

-

Tight tolerance control

-

Experience with complex PCB mechanical features

-

Fast lead time and stable mass-production quality

-

Strong support for industrial, automotive, EV, and telecom projects

Whether you need small prototype batches or volume production, PCBBUY ensures consistent quality across every counterbored hole.

7. Real Applications from PCBBUY

We frequently manufacture PCBs requiring:

-

Screw-mounted power modules

-

Industrial controller boards

-

Metal-housing mounting solutions

-

Aluminum substrate PCBs for lighting and power systems

Each application requires precise mechanical machining—something PCBBUY excels at.

8. Conclusion

Counterboring is a small detail that can significantly improve PCB reliability. With advanced CNC milling equipment, strict tolerance management, and years of experience, PCBBUY provides dependable counterboring services for customers worldwide.

If your design requires counterbores, feel free to send us your Gerber or drawings—we’ll be happy to provide a DFM review and fast quotation.

FAQ

Q1. What is the purpose of counterboring in PCB manufacturing?

Counterbores allow screw heads to sit flush, improving mechanical stability.

Q2. What tolerances can PCBBUY achieve?

Typical depth tolerance is ±0.05 mm with CNC Z-axis power-feed milling.

Q3. Can plated holes be counterbored?

Yes, but they require special review because plating thickness and structural integrity must be considered.

Q4. What do I need to provide in my Gerber?

Counterbore diameter, depth, hole size, plating type, and clear mechanical-layer markings.

Q5. Can PCBBUY counterbore aluminum PCBs?

Yes, PCBBUY supports counterboring on FR4, MCPCB, copper boards, and hybrid materials.

Industry Category