Understanding ENEPIG Thickness in PCB Manufacturing

By:PCB 07/29/2025 16:02

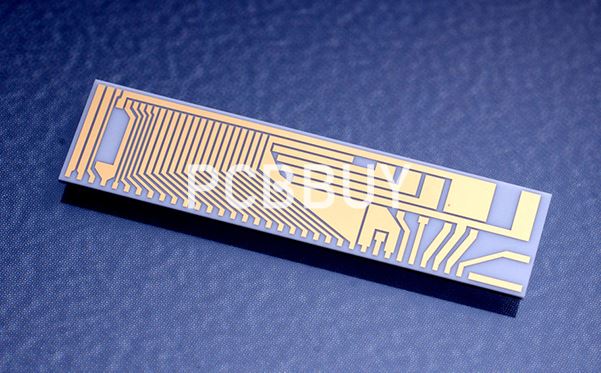

In the field of high-performance printed circuit boards, ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) has become a preferred surface finish, especially for applications requiring superior wire bonding, excellent corrosion resistance, and extended shelf life. One of the most critical aspects of ENEPIG performance is its metallic layer thickness. At PCBBUY, we take ENEPIG thickness control seriously as a key element of quality and reliability.

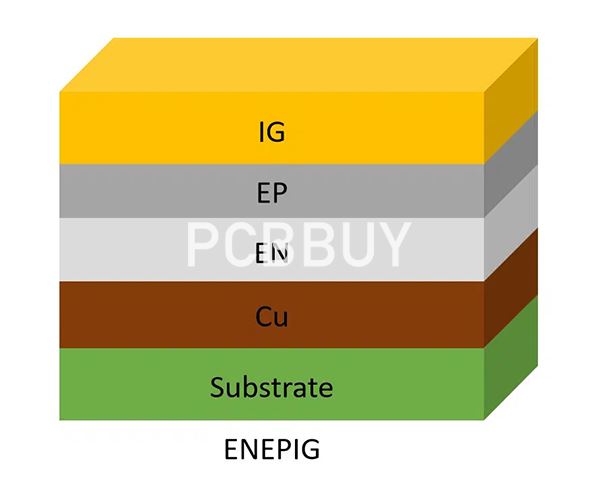

What Is ENEPIG and Why ENEPIG Thickness Matters?

ENEPIG is a three-layer surface finish system applied to exposed copper surfaces of PCBs. It includes:

-

Electroless Nickel (Ni): A barrier and foundational layer for subsequent finishes.

-

Electroless Palladium (Pd): Prevents nickel corrosion and improves bondability.

-

Immersion Gold (Au): Enhances oxidation resistance and solderability.

The thickness of each metallic layer directly impacts performance. An incorrect ENEPIG thickness can lead to:

-

Poor wire bondability (if Pd is too thin)

-

Signal integrity loss in RF circuits

-

Decreased solder joint reliability

-

Increased cost from excessive Au or Pd

Standard ENEPIG Thickness Specifications at PCBBUY

At PCBBUY, we manufacture ENEPIG-finished boards with strict control over plating thickness, in accordance with international standards (IPC-4556). Our standard capability includes:

|

Metal Layer |

Standard Thickness |

Remarks |

|

Nickel (Ni) |

200μ" |

Max limit: 300μ" |

|

Palladium (Pd) |

1–10μ" |

Pd + Au combined ≤ 30μ" |

|

Gold (Au) |

1–10μ" |

Controlled immersion |

We also accept customized thickness requests based on product applications, such as high-frequency RF boards or wire-bonded IC packages.

How PCBBUY Controls ENEPIG Thickness with Precision

ENEPIG plating involves complex chemical reactions, and thickness must be maintained within strict tolerances. PCBBUY ensures precision through:

-

X-Ray Fluorescence (XRF) Testing: Real-time, non-destructive measurement of metal layers

-

Titration Control Systems: To manage chemical concentration in Ni, Pd, and Au baths

-

Automatic Plating Lines: For consistent fluid flow, temperature, and time control

-

Data Logging and Traceability: Every ENEPIG batch is documented for QC history and compliance

How ENEPIG Thickness Affects PCB Performance

|

Performance Area |

ENEPIG Thickness Impact |

|

Wire Bonding (Gold/Al) |

Optimal Pd thickness (3–8μ") ensures strong metal-to-wire adhesion |

|

Solder Joint Reliability |

Uniform Ni and Au thickness improves wetting and joint strength |

|

Signal Integrity |

Thicker Ni can increase insertion loss in high-speed circuits |

|

Corrosion Resistance |

Proper Pd layer prevents nickel oxidation over time |

Too thin a Pd or Au layer can cause premature failure. Too thick leads to increased cost without performance benefit. Hence, balance is key—and PCBBUY ensures it.

ENEPIG Thickness vs Other Surface Finishes

|

Surface Finish |

Nickel (μ") |

Palladium (μ") |

Gold (μ") |

Key Characteristics |

|

ENEPIG |

200 |

1–10 |

1–10 |

Best for wire bonding, corrosion resistance |

|

ENIG |

100–200 |

– |

1–5 |

Good solderability, not ideal for wire bonding |

|

Hard Gold |

>300 |

– |

>30 |

Durable for edge connectors |

|

OSP |

– |

– |

– |

Organic coating, low cost |

Applications Requiring Precise ENEPIG Thickness

ENEPIG with controlled thickness is commonly used in:

-

Semiconductor packaging substrates

-

Medical devices and implantable PCBs

-

RF and microwave applications

-

Automotive safety electronics (ADAS, airbags)

-

Aerospace mission-critical systems

PCBBUY supports global OEM and Tier-1 manufacturers with ENEPIG PCBs for these industries.

Why Choose PCBBUY for ENEPIG Thickness Excellence?

-

✔ Experienced ENEPIG production lines with 24/7 plating monitoring

-

✔ Certified compliance with IPC-4556 and customer-specific specs

-

✔ XRF traceability report provided upon request

-

✔ Free engineering evaluation for custom Pd/Au/Ni stack-ups

-

✔ Fast turnaround for prototype and mass production

FAQs About ENEPIG Thickness

Q: Can PCBBUY provide tighter ENEPIG thickness tolerance than standard?

A: Yes, we can achieve tighter tolerances with special instructions. Please contact our engineering team for evaluation.

Q: Is the ENEPIG finish compatible with aluminum wire bonding?

A: Absolutely. We recommend a Pd thickness of 6–8μ" for optimal Al wire adhesion.

Q: Can I request 300μ" Ni or 15μ" Au for high-wear applications?

A: Yes, special requests like this can be fulfilled. Note that they may require process re-qualification.

Conclusion

ENEPIG is more than just a surface finish—its thickness is directly linked to your product’s electrical, mechanical, and reliability performance. At PCBBUY, we ensure every layer of ENEPIG is within spec and optimized for your specific application. Whether you're in telecom, aerospace, or medical electronics, trust us to deliver ENEPIG thickness with accuracy, consistency, and efficiency.

Contact PCBBUY now to request a quote or Gerber evaluation for ENEPIG PCBs.

Industry Category