Via Reliability in 8 Layer PCB Manufacturing Challenges

By:PCBBUY 01/17/2026 16:25

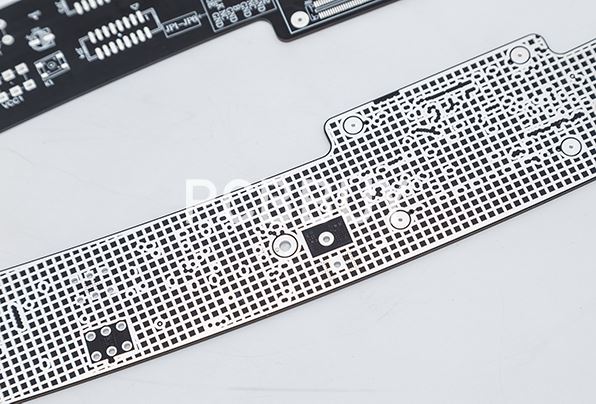

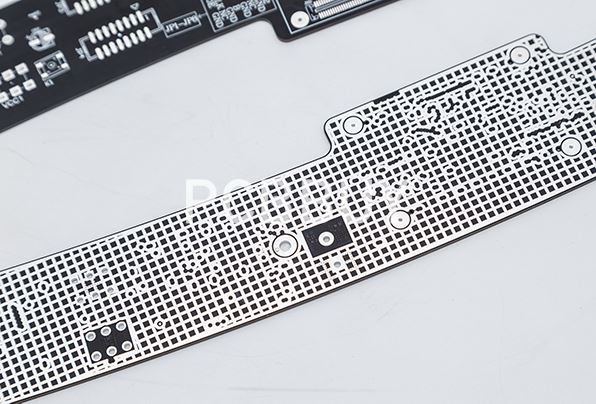

As PCB designs move toward higher density and increased functionality, via reliability in 8 layer PCB has become a critical factor affecting product performance and long-term reliability. Vias form the electrical and mechanical connection between layers, and any failure within the via structure can lead to intermittent connections, signal loss, or complete circuit failure.

For multilayer PCBs, especially 8 layer constructions, via reliability is closely linked to drilling accuracy, plating quality, lamination stability, and thermal stress resistance. This article explains the key factors influencing via reliability and highlights the manufacturing processes required to achieve stable, high-quality results.

What Is Via Reliability in Multilayer PCB?

Via reliability refers to the ability of a via to maintain electrical continuity and mechanical integrity throughout the PCB’s service life. Reliable vias must withstand:

-

Thermal cycling during assembly and operation

-

Mechanical stress from expansion and contraction

-

Electrical loading over time

In an 8 layer PCB, vias pass through multiple dielectric and copper layers, increasing the complexity of the via structure and the risk of failure.

Common Via Types Used in 8 Layer PCB

Several via structures are commonly used in 8 layer PCB designs:

-

Plated Through-Hole (PTH) Vias

-

Blind Vias connecting outer layers to inner layers

-

Buried Vias connecting inner layers only

-

Microvias for high-density designs

Each via type has unique reliability considerations depending on aspect ratio and plating requirements.

Via Structure and Material Considerations

A reliable via consists of a uniformly plated copper barrel bonded securely to the surrounding laminate. Key material-related factors include:

-

Copper adhesion to the hole wall

-

Dielectric material properties

-

Coefficient of thermal expansion (CTE) compatibility

Proper material selection and surface preparation are essential to prevent barrel cracking and separation.

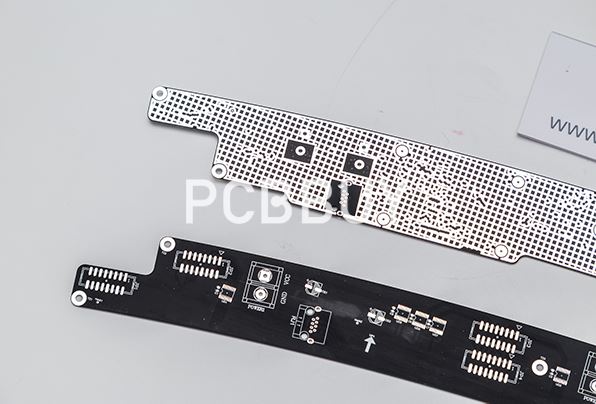

Manufacturing Challenges Affecting Via Reliability

High Aspect Ratio Drilling

As board thickness increases, achieving clean, accurately drilled holes becomes more challenging. Poor hole wall quality can weaken copper adhesion during plating.

Smear Removal and Hole Wall Preparation

Incomplete smear removal leaves resin residue on the hole wall, reducing plating reliability and increasing the risk of via failure.

Registration Accuracy

Precise layer-to-layer alignment is critical to ensure vias connect correctly to inner layer pads without breakout.

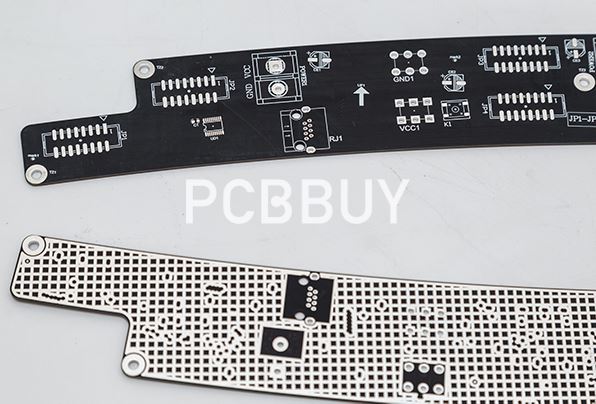

Plating Process Control and Via Reliability

Copper plating is one of the most critical steps influencing via reliability. Key process requirements include:

-

Uniform copper thickness along the via barrel

-

Adequate minimum plating thickness to meet reliability standards

-

Stable electroplating chemistry and current distribution

Insufficient or uneven plating increases the likelihood of cracks under thermal stress.

Thermal Stress and Via Reliability in 8 Layer PCB

During soldering and operation, PCBs undergo repeated thermal cycles. Differences in CTE between copper and laminate materials create mechanical stress within the via barrel.

In 8 layer PCB structures, this stress is amplified due to:

-

Increased board thickness

-

Multiple lamination interfaces

-

Heavier copper layers

Effective process control reduces the risk of barrel fatigue and cracking.

Inspection and Testing for Via Reliability

To verify via quality, manufacturers use several inspection and testing methods:

-

Micro-section analysis to examine via structure

-

Thermal stress testing to evaluate durability

-

Electrical continuity testing

These inspections ensure vias meet reliability requirements before final shipment.

Design Guidelines to Improve Via Reliability

Designers can improve via reliability by following these guidelines:

-

Maintain reasonable via aspect ratios

-

Select appropriate via diameters and pad sizes

-

Balance copper distribution across layers

-

Communicate stackup details early with the manufacturer

Good design-for-manufacturing practices reduce production risk.

Manufacturing Capability Required for Reliable Vias

Achieving high via reliability in 8 layer PCB requires:

-

Advanced CNC drilling systems

-

Precise desmear and surface preparation processes

-

Stable electroplating and thickness control

-

Controlled multilayer lamination and registration

These capabilities reflect a manufacturer’s technical strength in multilayer PCB fabrication.

Applications Requiring High Via Reliability

High via reliability is essential in:

-

High-speed digital electronics

-

Industrial control systems

-

Communication and networking equipment

-

Power and automotive electronics

In these applications, via failure can result in system instability or downtime.

Conclusion

Via reliability in 8 layer PCB manufacturing is the result of careful coordination between design, materials, and process control. From drilling and plating to lamination and inspection, each step contributes to the long-term performance of the via structure.

Manufacturers with strong via process capability can consistently deliver reliable 8 layer PCBs that meet the demanding requirements of modern electronic systems.

Industry Category