Via-in-Pad Feasibility for 8 Layer PCB Manufacturing

By:PCBBUY 01/23/2026 15:47

Introduction

As electronic products continue to evolve toward higher density and smaller form factors, via-in-pad (VIP) technology has become an important solution for routing constraints under fine-pitch components. When applied to multilayer designs, especially 8 layer PCB, evaluating the via-in-pad feasibility becomes critical due to increased complexity in lamination, drilling, plating, and reliability control.

This article explores the technical feasibility of via-in-pad in 8 layer PCB designs and explains the manufacturing capabilities required to produce reliable results.

What Is Via-in-Pad Technology?

Via-in-pad technology places a via directly inside a component pad, allowing signals to transition between layers without consuming additional routing space. Compared to traditional dog-bone fan-out structures, via-in-pad enables:

-

Higher routing density

-

Shorter signal paths

-

Improved electrical performance

However, via-in-pad requires advanced manufacturing processes to prevent solder wicking and surface irregularities.

Why Via-in-Pad Feasibility Is Critical in 8 Layer PCB?

In 8 layer PCB designs, via-in-pad feasibility is affected by several factors:

-

Increased board thickness and via aspect ratio

-

Multiple lamination interfaces

-

Higher thermal stress during assembly

-

Stricter flatness requirements for component soldering

Without proper process control, via-in-pad structures may lead to assembly defects or long-term reliability issues.

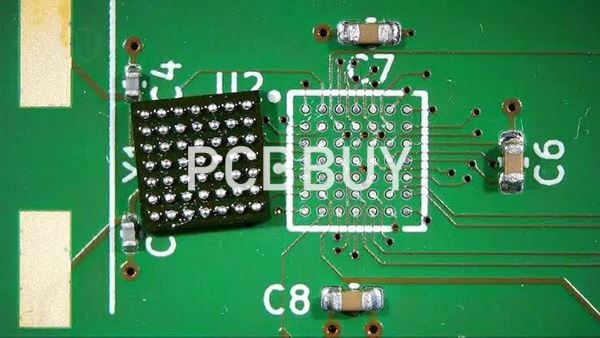

Types of Via-in-Pad Structures Used in 8 Layer PCB

Via-in-Pad Plated Over (VIPPO)

The via is filled and then capped with copper, creating a flat surface suitable for fine-pitch components.

Filled and Capped Vias

Vias may be filled with conductive or non-conductive materials before copper capping to prevent solder wicking.

Blind Via-in-Pad

Often used to reduce aspect ratio and improve reliability by limiting via depth.

Each structure has different manufacturing and reliability implications.

Via Filling Materials and Processes

Via filling is a key step in via-in-pad manufacturing. Common approaches include:

-

Non-conductive resin filling, widely used for stability and cost efficiency

-

Copper filling, offering superior electrical and thermal performance

After filling, planarization ensures a smooth and flat pad surface for soldering.

Manufacturing Challenges Affecting Via-in-Pad Feasibility

Several process challenges must be controlled to ensure via-in-pad feasibility in 8 layer PCB:

-

Void-free via filling

-

Uniform copper capping thickness

-

Surface flatness control

-

Reliable bonding during lamination

These challenges require advanced equipment and experienced process engineering.

Impact of Via-in-Pad on Reliability

Properly manufactured via-in-pad structures improve reliability by:

-

Eliminating solder wicking

-

Reducing thermal stress concentration

-

Enhancing electrical continuity

Poorly controlled via-in-pad, however, can lead to cracks, delamination, or intermittent connections during thermal cycling.

Design Guidelines for Via-in-Pad in 8 Layer PCB

To improve manufacturability and reliability, designers should consider:

-

Limiting via aspect ratio

-

Selecting appropriate via diameters and pad sizes

-

Using blind vias when feasible

-

Communicating stackup and via requirements early

Design-for-manufacturing collaboration is essential for successful via-in-pad implementation.

Inspection and Quality Control for Via-in-Pad

Manufacturers use multiple inspection methods to verify via-in-pad quality:

-

X-ray inspection to detect voids

-

Micro-section analysis to examine via structure

-

Surface flatness measurement

These inspections ensure via-in-pad structures meet assembly and reliability standards.

Manufacturing Capability Required for Via-in-Pad in 8 Layer PCB

Successful via-in-pad production requires:

-

Precision drilling and via filling equipment

-

Stable copper plating and planarization processes

-

Controlled multilayer lamination

-

Experienced engineering support for feasibility review

These capabilities are critical for complex multilayer PCB manufacturing.

Typical Applications Using Via-in-Pad in 8 Layer PCB

Via-in-pad technology is commonly applied in:

-

Fine-pitch BGA and CSP packages

-

High-speed digital systems

-

Communication and networking equipment

-

Compact industrial electronics

Conclusion

Via-in-pad feasibility for 8 layer PCB depends on a combination of thoughtful design and advanced manufacturing capability. From via filling and copper capping to lamination and inspection, each process step must be carefully controlled to ensure long-term reliability.

Manufacturers with strong via-in-pad expertise can support high-density 8 layer PCB designs that meet both electrical and mechanical performance requirements.

Industry Category