What Are Surface Finishes in PCB Manufacturing Process?

By:PCBBUY 01/07/2022 09:59

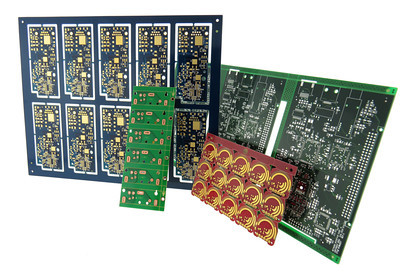

PCBs are made of copper to ensure electric currents flow efficiently. These metals require appropriate protection from the elements to avoid oxidation and other corrosion. A range of finish types provide different levels of protection against deterioration. They also aid in certain use, such as with soldering. Various circuit board finishes are available, from options that are affordable and easy-to-apply to expensive or difficult-to-manage finishes used in only the most advanced applications.

In this passage, we are providing you all the information about surface finishes in PCB. If you are going to learn more about surface finishes in PCB, please check and read the content below in this passage.

Wanna know PCB knowledge? Check and read for more.

What are the basic features of surface finishes in PCB?

A PCB surface finish is an intermetallic joint between the bare copper of the solderable area of the printed circuit board and the components. Circuit boards have a base copper surface that is susceptible to oxidation if left without a protective coating, hence the requirement of the surface finish. It is also responsible for preparing the PCB surface for soldering components onto the board during assembly and enhances the shelf-life of the board.

It impacts various features such as:

· The quality of the inter-metallic joint

· The process yield

· Rework for production batches along with the scrap rate

· Testing ability

· Cost of the manufacturing process and also

· The rate at which the board will fail while being used for its intended application

What are the main types of surface finishes in PCB?

With increasing demands for thin, high-density, fast speeds, and lightweight applications, the solder finish will make all the difference.

Modern surface finishes are lead-free, in accordance with Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives, and include:

· ENIG (Electroless Nickel Immersion Gold)

· ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold)

· Electrolytic Nickel/Gold - Ni/Au (Hard/Soft Gold)

· Immersion Silver

· White Tin or Immersion Tin

· Lead Free HASL (Hot Air Solder Leveling)

· OSP (Organic Solderability Preservatives)

Choosing the correct PCB surface finish for your application requires taking factors into account like cost, the final application environment (e.g. high-heat/thermal, vibration/stability, RF), component density/selection, lead/lead free requirements, shelf life, shock/drop resistance, production volume, and throughput.

Due to the increased demand for improved performance of electronic applications, surface finishes have also been upgrading. Because of tighter PCB topography the HASL surface finish is quickly being replaced by gold-based surface finishes like ENIG, ENEPIG, and soft/hard gold. The gold-based surface finishes have a lot to offer in terms of features and benefits when used in applications.

Why surface finish is important in PCB?

The selection of the surface finish could be the most important material decision made for the component assembly.

Each surface finish has its own advantages and disadvantages, which influences:

· Process yield

· Amount of rework

· Ability to test

· Scrap rate

· Field failure rate

· Cost

What are the applications of PCB surface finish in different industries?

· Automotive: OSP, Silver, Immersion Tin

· High-end consumer products: OSP, ENIG, Silver

· Basic consumer electronics: OSP, Immersion Tin

· Mil/Aerospace: HASL, Immersion tin, ENIG, ENEPIG

· Telecom: Silver, OSP, ENIG

· Medical: ENIG, ENEPIG, Silver

Industry Category