By:PCBBUY

05/23/2023 15:34

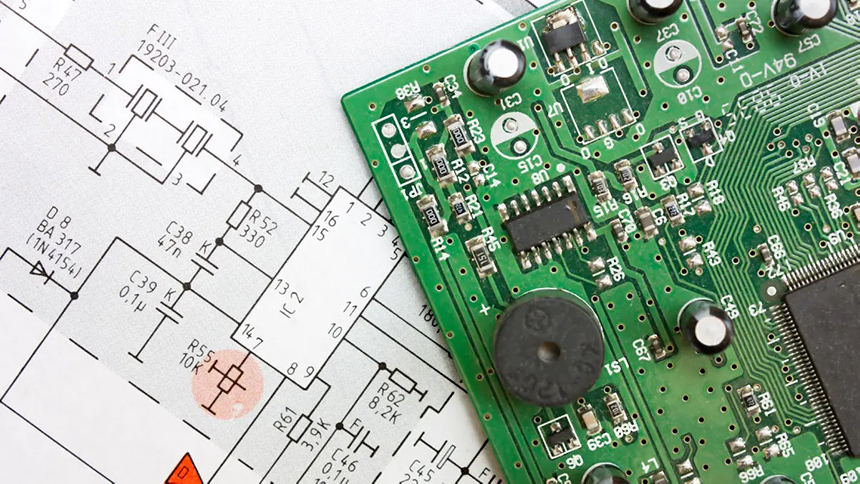

In the manufacturing and assembly of printed circuit boards (PCBs), various devices play key roles. Although different sources may define "essential" differently, several devices are extremely important in the entire process:

In this passage, we are going to provide you all the information of PCB equipment. If you are going to learn more about PCB equipment and the function, please check and read the content below.

Solder Paste Printing Machine

It is a key device in the initial stage of PCB assembly. When working, it first fixes the PCB in the automatic printer, then uses a scraper to apply an appropriate amount of solder paste to the pads. Then the blade moves across the stencil, distributing the solder paste evenly in the holes, leaving a layer of solder paste only in the areas where components will be placed later. After that, the machine removes the stencil. It ensures that the solder paste covers the specified positions accurately, laying the foundation for subsequent component welding. Problems in solder paste printing may lead to weak soldering, cold solder joints, etc., reducing the overall performance of the PCB.

Pick and Place Machine

It picks up surface-mount technology (SMT) components from trays and places them precisely on the solder paste of the PCB according to pre-programmed positions. In the past, this operation mainly relied on manual work with tweezers, which was inefficient and error-prone. Today's pick and place machines are highly automated, with very fast speeds—up to 30,000 components per hour. They greatly improve production efficiency and the accuracy of component placement, and are key to achieving large-scale and high-efficiency production.

Automatic Optical Inspection (AOI) Machine

It is used to conduct a comprehensive inspection of the assembled PCB. By using cameras to capture images and image processing algorithms, it can quickly and accurately identify various defects such as missing components, wrong placement, and solder bridges. Manual inspection is prone to missing subtle defects, but the AOI machine, with its high-precision detection capability, ensures that the PCB quality meets standards. It finds and feeds back problems in a timely manner, facilitating subsequent corrections, thus effectively reducing the defect rate and ensuring product quality.

In addition to these three, other equipment used in PCB manufacturing and assembly includes reflow ovens (for welding), solder paste inspection (SPI) machines, wave soldering machines (for through-hole components), etc. They all play important roles in different links.

PCB Instant Quote

· Solder Paste Printing machine

· Solder Paste Inspection (SPI) machine

· Glue Dispensing machine

· Pick-and-Place machine

· Reflow Soldering machine

· Wave Soldering machine (for through-hole components)

· Automatic Optical Inspection (AOI) machine

· In-Circuit Test (ICT) Fixture

· Functional Validation Test (FVT) Fixture