What Are the 5 Common Causes of Electronic Component Faults in PCB Manufacturing?

By:PCBBUY 11/22/2021 09:32

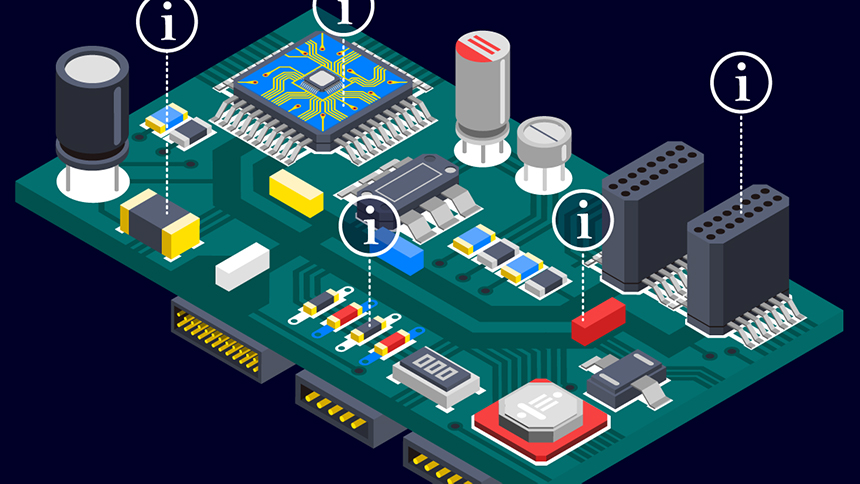

PCB traces are metal wires connected between components. These traces are usually copper strips and sometimes aluminum or silver. The PCB material, on which the components and traces are placed, is made of insulator material(dielectric), typically fiberglass impregnated with resin. This dielectric material can be of various kinds depending on the application of the circuit board.

PCBs comprise of numerous components including through-hole components and surface mount devices (SMD). Defects may arise due to several reasons during manufacturing, assembly, and shipping. There should be a focus on continuous improvement in the areas that are prone to failures.

If you are going to learn more about causes of electronic component faults in PCB, please check and read the content for more information.

5 Common Causes of Electronic Component Faults in PCB Manufacturing

Electronic component failure is when a component is not functioning or performing as expected. It eventually damages the product. These defects may result in a complete breakdown or degradation in the performance of the device.

1. Unprotected Components

Circuit boards are subjected to various conditions before being installed for operation. These include board fabrication, PCB assembly, shipping and storage. During all of these phases, the possibility of contamination exists. For the manufacturing of critical boards—such as those used in some medical device applications—ionic contamination can be a major problem. During shipping and storage, unprotected boards are subject to oxidation and other contamination that may eventually lead to a premature board and/or component failure.

2. Moisture Sensitive Components

One of the major sources of contamination that threaten electronic components on circuit boards is moisture. Moisture can be acquired during component and/or board manufacturing. Additionally, condensation can occur on the board and within component packages. This is most common when boards are stored in packaging where internal temperatures are colder than the external environment. Certain components are more susceptible to moisture than others and this should be a consideration when making your selections.

3. Temperature Sensitive Components

PCBAs are installed everywhere these days. This includes extreme environments where temperature, pressure and corrosion can affect the operation, damaging boards and components. For example, components used for aerospace electronics must be able to withstand temperatures that range from very cold (as low as minus 184° F in the thermosphere) to severely hot (approximately 5,792° F during a rocket launch). When selecting these components, especially when a COTS solution is implemented, thermal sensitivity must be a major concern.

4. Components Vulnerable to Power Surges

Excessive heat on circuit boards can cause several failure mode issues. These include structural fatigue and spikes in the current flow. The latter can also be due to power supply surges or, in the case of high voltage PCBAs used in industrial applications, arcing. Irrespective of the source, large currents can wreak havoc on boards and destroy vulnerable unprotected components.

5. Components Vulnerable to Radiation

For most PCBA development, radiation concerns are limited to minimizing EMI or trying to attain electromagnetic compatibility with its environment. This is not insignificant as excessive noise can degrade signal integrity to the point where reliable TX/RX is not possible. For boards deployed aboard space vehicles where failure is not an option, radiation effects on electronic devices can cause significant damage.

What are the environmental factors of electronic PCB failures?

If you have resided in a warm-weather climate (Florida) for the majority of your life, then you can relate to a new recruit (Me) serving in the Navy in Great Lakes, Illinois experiencing culture shock during his first Chicago, winter. I can attest that temperature is a disruptive environmental factor.

Well, temperature is also a disruptive environmental factor when it pertains to electronic circuits. Temperature changes can indeed cause an electronic circuit to fail and in turn, cause a PCB’s malfunction. As you may know, with temperature changes, you will experience expansion and contraction of the PCB. These expansions and contractions, in turn, brings about the potential risk of a warped board and damage to solder joints.

Another equally devastating environmental factor is moisture. If moisture is introduced to your electronic circuits, it can cause rust, oxidation, and corrosion.

Industry Category