Steps of SMT Factory in PCB Industry: A Complete Guide

By:PCBBUY 05/22/2023 15:12

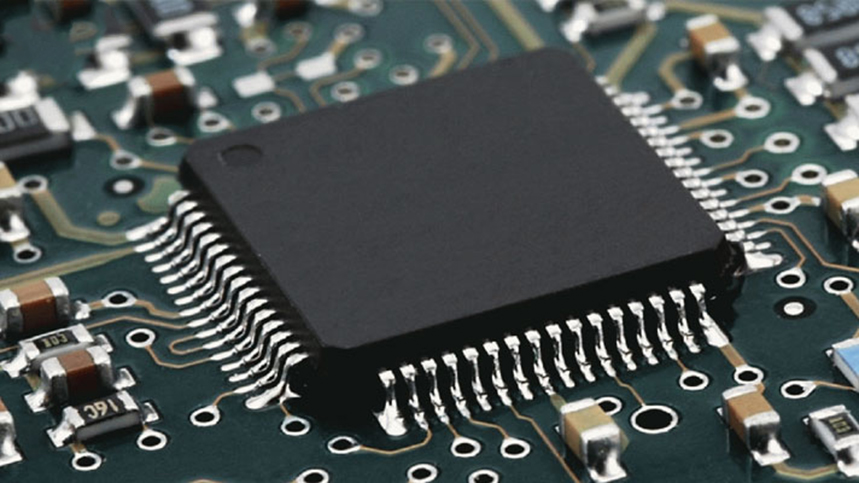

Introduction to SMT Factory in PCB Industry

Surface Mount Technology (SMT) revolutionized PCB manufacturing by enabling high-speed, automated assembly of electronic components. Since its introduction in the 1960s, SMT factory processes in the PCB industry have evolved to support miniaturization, precision, and mass production. This guide explores the key steps of SMT factory in PCB industry, including solder paste application, component placement, reflow soldering, and PCB quality inspection.

Step 1: Solder Paste Printing – The First Critical Step in SMT Factory

The SMT factory process in PCB industry begins with solder paste application, a crucial stage for ensuring proper electrical connections.

How It Works:

· A stencil (laser-cut stainless steel) aligns over the PCB.

· Solder paste (96.5% tin, 3% silver, 0.5% copper) is spread across the stencil.

· A squeegee blade forces paste onto PCB pads at 0.1-0.15mm thickness.

Industry Standard:

· IPC-7525 defines stencil design rules for optimal paste deposition.

· Defect Rate: <1% for high-end SMT factories.

Step 2: Component Placement – High-Speed Automation in SMT Factory

After solder paste application, pick-and-place machines mount components at speeds up to 50,000 CPH (components per hour).

Machine Types Used in SMT Factory:

|

Machine Type |

Speed (CPH) |

Accuracy |

Best For |

|

High-Speed |

30,000-50,000 |

±0.025mm |

Small passives (0402, 0201) |

|

Multi-Function |

10,000-20,000 |

±0.01mm |

BGAs, QFPs |

Key Consideration:

· Vision alignment systems ensure <10µm placement accuracy.

Step 3: Reflow Soldering – The Heat-Driven Step in SMT Factory

Reflow soldering melts solder paste to form permanent connections.

Reflow Profile (Critical for SMT Factory Success)

|

Zone |

Temperature |

Function |

|

Preheat |

150-180°C |

Activates flux, removes moisture |

|

Soak |

180-200°C |

Prevents thermal shock |

|

Reflow |

230-250°C |

Solder melts (Peak: 245°C for SAC305) |

|

Cooling |

<200°C |

Solidifies joints |

Defect Prevention:

· Tombstoning (imbalanced heating) minimized with proper thermal profiling.

Step 4: Inspection & Testing – Quality Control in SMT Factory

Post-soldering inspection ensures reliability before final assembly.

Inspection Methods in SMT Factory:

|

Method |

Defects Detected |

Speed |

|

AOI (Automated Optical) |

Solder bridges, misalignment |

20-30 sec/board |

|

X-Ray (AXI) |

BGA voids, hidden joints |

1-2 min/board |

|

ICT (In-Circuit Test) |

Electrical faults |

High-speed |

Industry Standards:

· IPC-A-610 Class 2/3 for consumer/industrial electronics.

Step 5: Conformal Coating & Final Assembly

For harsh environments, SMT factories apply protective coatings:

· Acrylic (Fast drying)

· Silicone (Flexible, high temp)

· Urethane (Chemical resistant)

Final Testing Includes:

· Functional testing (power-up verification).

· Environmental stress screening (ESS).

How to Choose the Best SMT Factory in PCB Industry?

1. Equipment & Technology

· Look for high-speed SMT lines (e.g., Fuji NXT, Siemens SIPLACE).

· Ensure AOI/X-ray inspection capability.

2. Industry Experience & Certifications

· IPC, ISO 9001, IATF 16949 certified factories.

· Case studies in automotive, medical, or 5G PCB assembly.

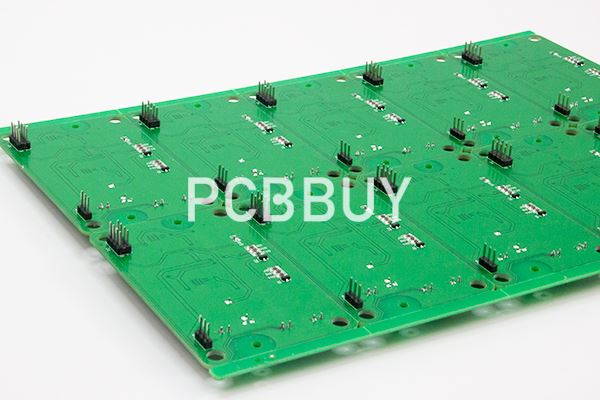

3. Delivery & Scalability

· Quick-turn prototyping (24-48hrs).

· Mass production capacity (>1M boards/month).

Future Trends in SMT Factory Processes

· AI-Powered Defect Detection (Reduces false calls by 30%).

· 3D Solder Paste Inspection (SPI) for zero-defect manufacturing.

· Hybrid SMT-THT Lines for complex assemblies.

Conclusion

Understanding the steps of SMT factory in PCB industry ensures high-quality, reliable electronics manufacturing. From solder paste printing to final testing, each stage impacts yield and performance.

Industry Category