What Are the 5 Important Aspects Quality Control in PCB Manufacturing?

By:PCBBUY 03/23/2022 10:12

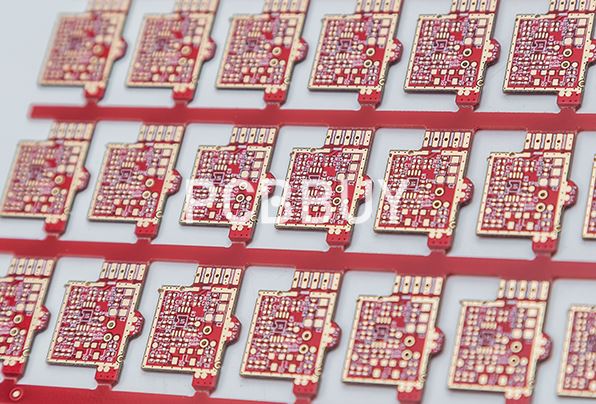

The quality of key procedures of PCB manufacturing influences a lot on performance and reliability of PCBs and quality control on that has to be strengthened. The key technological procedures formulated by PCB manufacturer have to be monitored and checked including etching, via mentalization etc. so as to ensure absence of burr, gap, bridge defect and void. Furthermore, quality control has to be overtaken on stacking of multi-layer PCBs in order to ensure the thickness, adhesive intensity and positional accuracy.

In this passage, we will provide all the professional knowledge about quality control in PCB manufacturing. If you are searching for more information of quality control in PCB manufacturing, please check and read the content below for more.

What are the methods of PCB quality control?

PCB first article inspection process Ensuring quality during printed circuit board manufacturing is a continual process from start to finish. These six areas should be highlighted by a PCB contract manufacturer to demonstrate their overall commitment to the quality control process.

IPC Certification

With IPC training and certification, the PCB CM can provide the highest levels of manufacturing quality to its customers. In addition, IPC certifications ensure that the entire staff is working to the same requirements and standards which guarantee a consistent and uniform approach to the different assembly processes. Many CMs will also maintain a certified IPC trainer on-site, which allows them to keep their staff current with their required biannual IPC certifications.

Component Expertise

Component failures on printed circuit boards can be a very difficult problem to deal with. The best PCB CMs will have a well-documented process for inspection and quality assurance to make sure that the parts used on your board are of the best quality. In addition to that, the CM should employ component engineering specialists who can work with a vast network of component manufacturers and suppliers in order to get you the best parts at the best price in the least amount of time.

Process Controls

The step by step process of PCB assembly should be well documented by the CM in accordance with ISO regulations for quality control processes, risk management, and traceability. In addition, the CM should also have well-documented process controls in place to govern the quality of the manufacturing operation by regulating soldering temperatures, shelf life, and cleanliness standards.

Assembly Checks

During PCB assembly, there should be multiple inspection points to allow inspectors to focus on the previous operation performed instead of trying to catch everything at the end. These checks should be performed both manually and with automated inspection equipment to find potential problems with solder joints, and incorrectly placed components.

Inspection and Test

Once the board is completed it needs to be inspected again, and the PCB CM should have a detailed inspection process prior to releasing the final product back to you. Another part of the overall quality assurance process is testing the board. There are different methods of testing for the circuit board, and you can expect that the CM will have prepared a full test plan for the design based on your needs and input.

Functional Workspace

The final area of quality to consider in a PCB CM is in how they are set up to do the job. Creating precision electronics requires a neat and orderly workplace with properly maintained and up-to-date equipment that is equal to the task. As it has been said, quality is never an accident; it is always the result of intelligent effort. The facilities should reflect this by how assembly lines are laid out, and the company goals and culture should reflect a positive attitude and vision as well.

What are technologies of PCB quality control methods?

The most commonly utilized PCB quality inspection methods and tools of today are:

Visual – For low volume production runs, one effective form of inspection is for someone (often the person who performed the assembly) to simply look at it with their own eyes. This doesn’t just mean a quick glance; they must meticulously check each connection in a well-lit environment.

Microscope – To put less of a strain on their eyes, inspectors can use handheld optical tools such as magnifying glasses or jeweler’s loupes to achieve enlarged views of the board’s components. For an even closer look, they can use USB microscopes that project PCB connections onto a large screen for detailed inspection.

In Circuit Tests – This capacitance test encompasses two different methods of electronic inspection: bed of nails and fixtureless. Bed of nails testing contains a series of small spring-loaded pogo pins that press into various test points to measure resistance. Fixtureless or flying-probe testing sends machine-operated probes across the PCB to check test points at breakneck speeds.

X-Rays – X-rays offer a non-invasive, though expensive, way to visually inspect for proper PCB assembly – the same way that one would compare to a photograph or microscopic image.

Saws – Slicing through a PCB with a saw is destructive to the individual board, but can provide valuable insight into the bigger picture of the overall assembly process.

Automated Optical Inspection (AOI) – AOI systems are available in cheap and commercial grades. Cheap AOI systems utilize inexpensive webcams in conjunction with Open Source Computer Vision (OpenCV) to compare webcam PCB images with those of a “perfect” board and identify incongruences or defects. Commercial AOI uses higher quality cameras and RBG LEDs to reflect light and check for connection faults and solder quality.

Functional Testing – This testing method is essentially a full trial run of the PCB once it has been manufactured. Operators power on the PCB and program it to perform a series of self-tests.

Inspection cameras – A preferred tool for PCB quality assurance, inspection cameras allow operators ergonomic viewings with the naked eye. These high-resolution camera images are projected onto computer screens and manipulated such that microscopic details can be inspected and easily shared with different departments for further review.

Industry Category