What Are the Applications of Blind Via PCB?

By:PCBBUY 12/08/2023 16:33

PCBs with blind vias follow the standard procedure of making multilayer PCBs, only till the drilling stage. They offer extra holes that make a connection between only two layers if the PCB is four-layered. Before starting the PCB designing procedure, decide what build-up are you going to use and check with the PCB manufacturer.

In this passage, we will provide all the details about the PCBs with blind vias. If you are searching for the professional knowledge about blind vias in PCB, please check and read the content below for more information.

What Are the Applications of Blind Via PCB?

This part will take a closer look at the two primary uses of blind vias in circuit boards. It is essential to realize that you can minimize your circuit board layers by expanding the ball-grid getaway channel. You can achieve that by creating blind vias.

Are you experiencing difficulties when penetrating through-hole vias for designing and trace breakout of BGA? If so, try increasing the getaway channels on the internal and lower layers with blind vias. Alternatively, you can use blind vias to reduce your circuit board aspect ratio.

Mostly, circuit board BGA components come with various pitches. For example, a 4.00mm radius board contains 0.8mm and 1.27mm pitch BGAs. Remember, the smallest size via hole is determined by both the drill and board aspect ratios.

Why we process blind via on PCB?

There are two basic ways to manufacture PCBs with blind vias. These are either by laser drilling or sequential layer build. Blind via holes may be drilled by a laser through a thin layer of insulating dielectric, usually stopping where the laser beam meets an internal copper pad. Laser drilled blind vias have limitations because the drill hole is small, its depth can be no more than its diameter to ensure adequate penetration of the copper plating chemistry. Therefore, it can commonly only penetrate through just one layer starting from the outside layer.

In the sequential build method, pairs of layers are drilled and plated before bonding. Because these pairs of layers are plated with the hole open at both ends, the plating chemistry penetrates the hole quite easily and the blind via can be designed to pass through multiple layers. By combining the appropriate sequence of bonding, drilling and plating, a wide variety of blind via constructions is possible. This depends on if the blind via can pass through an even number of layers, starting with an outside layer.

What are the main types of blind via on PCB?

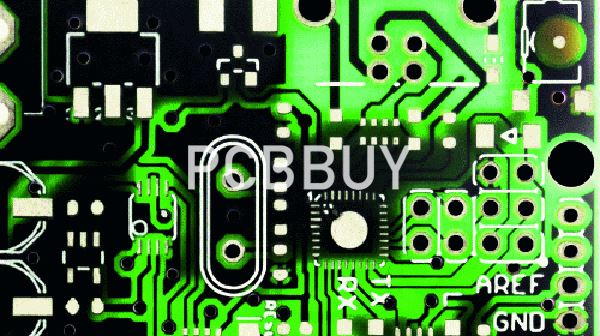

There are four categories of blind vias for your information, and we will discuss each of them in detail here. The diagram below shows the different types of PCB vias.

Photo-Defined Blind Via PCB

You can make a photo-defined blind by coating a photo-reactive resin sheet to a core. The core should consist of laminated traces enriched with planes and submerged signal layers. Remember to cover your photo-reactive sheet with patterns that shield the points where you will make the holes. You should also expose the sheet to wavelength rays to harden the residues on the board. After that, immerse your circuit board in a dying mixture to eliminate any unwanted substance from the holes. When you have finished the scraping process, plate copper into the holes and on the surfaces are to form the board's surface layer.

Sequential Lamination Blind Via

You can make this type of blind vias by passing a thin laminate piece through the two-faced PCB process. First, you need to drill, coat, and sketch the laminate to outline the characteristics that will make your PCB's second layer. Leave the solid copper material on the other PCB part to act as your board's first layer. It would be best if you also laminated your subassembly with the different board layers. Finally, pass your product through the process of making the surface layers of a multilayer board.

Controlled Depth Drilled Vias

As illustrated in figure 1, you can make controlled-depth vias using the through-hole via approach. However, you should set your drill to pierce only halfway through the board. You also need to place a pad on the second layer so that the drill penetrates it. Besides, it would help if you were cautious to ensure there are components underneath the percolated hole, forming contact with it. Lastly, you need to coat copper in the percolated hole concurrently with plating copper in the through-hole blind vias.

How to process blind via on PCB?

The use of blind holes and buried holes is an effective method to increase the density of multilayer boards, reduce the number of layers and board size, and significantly reduce the number of plated through-holes. Almost all BUM boards use buried and blind via structures. Buried holes and blind holes are mostly small holes with a diameter of 0.05 to 0.15 mm. Buried holes are manufactured on the inner thin laminate using the same process of manufacturing double-sided PCBs. In contrast, the manufacturing of blind holes started with a small hole CNC bed that controls the Z-axis depth, laser drilling, plasma etching, and photo-induced holes are now commonly used.

Laser drilling has carbon dioxide laser machine and Nd: YAG ultraviolet laser machine. The carbon dioxide laser drilling machine of Hitachi, Japan, has a laser wavelength of 9.4 Hongm, and one blind hole is drilled three times, which can drill 30,000 holes per minute. With the development of electronic products that require high density and high precision, the same requirements are put forward on circuit boards accordingly. The most effective way to increase the PCB density is to reduce the number of through-holes and accurately set blind holes and buried holes.

The process of designing and making buried holes is more complicated and more costly than traditional multilayer boards. The figure shows the difference between the traditional inner layer and the inner layer with buried holes.

Industry Category