What Are the Applications of FPC in PCB?

By:PCBBUY 12/14/2023 11:37

FPC is unique because, unlike PCBs, they can bend and flex. Furthermore, they typically offer greater heat dissipation than their PCB counterparts, which can prolong the electronics in which they are used. All FPCs are made using a flexible substrate, such as polymide. In this passage, if you are looking for more knowledge of FPC, please check and read the content below

What Are the Applications of FPC in PCB?

FPCs are a great lightweight and thin wiring material. These circuits play a significant role as extremely functional modules. Flexible printed circuits are used in several applications such as;

Mobile phones: Since FPCs are lightweight and extremely thin; they can save the volume of a device and easily connect the buttons, battery, and microphone. For instance, the FPC adapter is used for mobile phones.

Automobile: Flexible printed circuits are used in the automobile industry. These circuit boards are used for designing the led light, automotive powertrain, and the sensor for engine control of a car.

Medical equipment: These materials feature special properties that make them ideal for designing some medical equipment like an ultrasonic probe.

Robotics: FPC is flexible and as such, robotics engineers used it as wiring material for the legs and arms of a robot. It is used in the moving areas of robots.

Computer and LCD screen: The IC configuration and the thin thickness of FPC enable engineers to convert the digital signal into an image and display it via the LCD screen.

What is the basic of FPC in PCB?

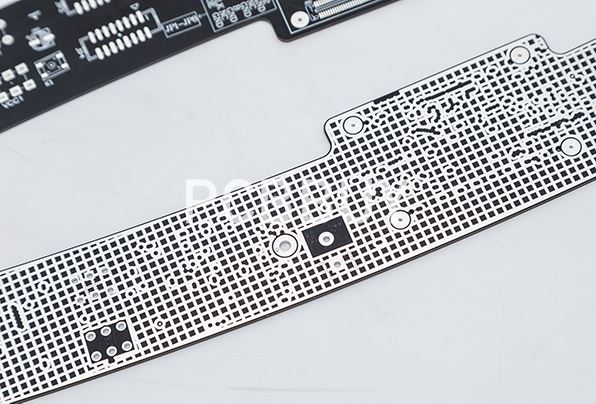

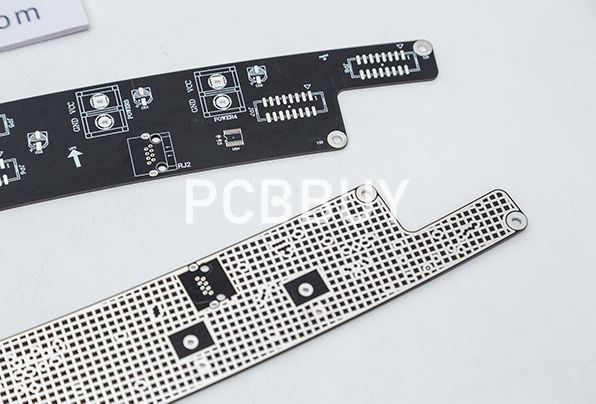

Many people in the PCB industry know that FPC is a type of PCB, also know as “flexible PCB”. FPC is made of flexible substrates such as polyimide or polyester film. It has the advantages of high wiring density, light weight, thin thickness and high flexibility. It can withstand millions of times of dynamic bending without damaging the wires, and can be moved and retracted arbitrarily according to the requirements of the space layout to realize three-dimensional assembly, achieving the effect of component assembly and wire connection integration. It has advantages unmatched by other types of circuit boards.

What are the differences of FPC and PCB?

PCB, which is a printed circuit board, is often referred to as a hard board.It is the supporting body of electronic components and is a very important electronic component.PCB generally USES FR4 as the base material, also known as hard board, can not be bent, flexure.PCB is generally used in some places that do not need to bend and have relatively hard strength, such as computer motherboard, mobile phone motherboard, etc.

The FPC is actually a kind of PCB, but it is quite different from the traditional printed circuit board. Call it a soft board, and the full name is a flexible circuit board. FPC generally uses PI as the base material, which is a flexible material that can be bent and flexed at will. FPC generally requires repeated flexing and the linking of some small parts, but now it is more than that. At present, smart phones are thinking about bending prevention, which requires the use of FPC, a key technology.

What are the types of FPC in PCB?

There are various flex circuit boards. Normally, they are designed according to diverse configurations and specifications. It's worth pointing out that they are also categorized based on layers. Let's get to understand the different types of flex circuit boards based on configurations and on layers.

HDI Flexible Circuit Boards

These circuit boards are characterized by high density interconnect. If you are looking for printed circuit boards that have a higher performance, these are the ones to opt for. Basically, they produce a superior level of performance compared to the normal flexible circuit boards. The reason why they have a higher level of performance is that they incorporate various features and that they have advanced designs and construction. Additionally, HDI flexible printed circuit boards use thinner substrates compared to the normal ones. This goes a long way to improve their performance as well as decrease their sizes.

Rigid-Flex PCBs

Just like the name suggests, these particular circuit boards are a combination of flex and rigid printed circuit boards. Generally, a rigid-flex circuit board configuration contains a series of rigid circuits joined together by flex circuits. The advantage of the hybrid circuits is that they give designers the opportunity to enhance the ability of circuits. It's important to highlight that the rigid areas come in handy in the mounting of several components including connectors and chassis. On the other hand, the flexible areas are used to ensure resistance that is vibration free.

What is the proper material for FPC in PCB?

Usually-applied substrate material for flexible PCB includes PI (polyimide) film and PET (polyester) film apart from which polymer film is also available like PEN (polyethylene nphthalate), PTFE and Aramid etc. Substrate materials film should be picked up based on their performance and cost.

The leading substrate material for flexible copper clad laminate (FCCL) covers PI, a type of thermosetting resin that won't reach a temperature to become softened or be able to flow. However, it can still maintain flexibility and elasticity after thermal polymerization, which is different from majority of thermosetting resin. PI features high thermal resistance and excellent electrical characteristics. However, PI leads to high humidity absorption and bad tear strength, which should be improved.

Industry Category