What Are the Characteristics during Automotive PCB Design?

By:PCBBUY 12/25/2023 16:07

The relationship between trace width and current carrying capacity in PCBs is relatively straightforward: trace cross-sectional area and temperature rise are the key determinants of current carrying capacity, with cross-sectional area directly related to copper thickness and trace width.

However, this does not mean current carrying capacity is strictly proportional to cross-sectional area. As many have found, calculating a trace’s maximum current-carrying limit based solely on width and temperature rise is not always a simple process.

It’s important that your PCB manufacturer is capable of producing very small circuit boards as most vehicle types that use printed circuit boards only allow a limited amount of space for electronic control devices. Please check and read the content below for more information of automotive PCB manufacturing.

Key Characteristics of Automotive PCB Design

1. High-Frequency Substrate Requirements

Automotive safety systems such as collision avoidance and predictive braking function similarly to military radar, relying on automotive PCBs to transmit microwave high-frequency signals. This requires substrates with low dielectric loss—typically PTFE, unlike standard FR4 materials. Drilling PTFE and other high-frequency substrates demands specific drilling and feed speeds.

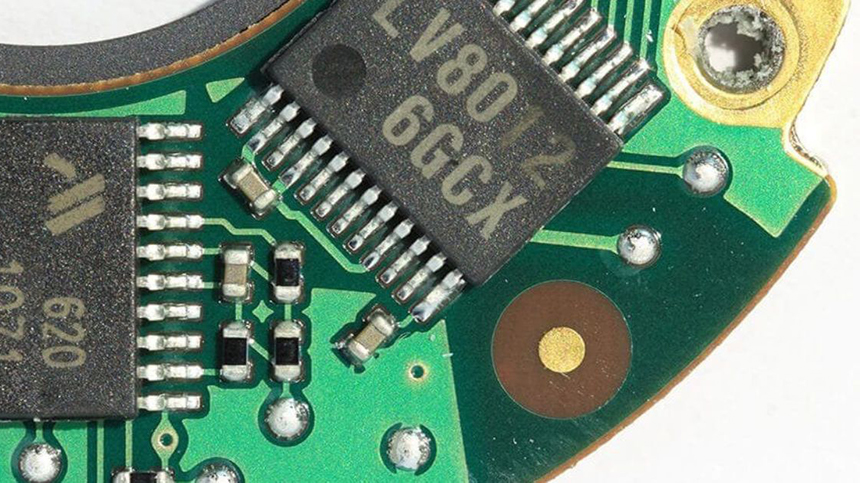

2. Thick Copper PCB Specifications

High-density, high-power automotive electronics, along with hybrid and electric vehicles, require advanced power transmission systems and expanded electronic functions. These needs place higher demands on heat dissipation and high-current handling capabilities, driving the use of thick copper PCBs.

Fabricating thick copper double-layer PCBs is relatively manageable, but thick copper multi-layer PCBs present greater challenges. The core difficulties lie in thick copper pattern etching and gap filling for uniform thickness.

3. Component Embedding Technology

Component-embedded PCBs were first widely adopted in mobile phones to boost assembly density and reduce component size. This technology has since been adopted by other electronic devices, including automotive electronics.

There are multiple manufacturing methods for component-embedded PCBs, depending on the embedding approach. For automotive electronics, four main manufacturing methods are commonly used.

Types of Automotive PCBs

To meet strict requirements for space, weight, and cost, the automotive industry uses various PCB types, distinguished by structure, material, and substrate. The main types of automotive PCBs are as follows:

Rigid PCBs: Traditional non-flexible boards, usually made of FR4. Applications include display monitors and reverse camera screens.

Flex PCBs: Constructed with flexible plastic substrates (e.g., polyamide, polyetheretherketone/PEEK, or transparent polyester films). Their ability to twist and bend makes them ideal for tight or irregular spaces, such as connecting displays, control panels, and light switches.

Rigid-Flex PCBs: Combine the advantages of rigid and flex PCBs. Common applications include automotive lighting systems.

LED PCBs: High-power, high-brightness LEDs (now widely used in automotive lighting) require PCBs with excellent heat dissipation. These are typically metal-based (e.g., aluminum) and used in turn signals, headlights, and brake lights.

HDI PCBs: High Density Interconnect (HDI) PCBs feature high connection density per unit area, with finer lines/spaces, smaller vias and capture pads, and higher pad density. Widely used in infotainment systems, they improve wiring quality while reducing solution weight and size.

Industry Category