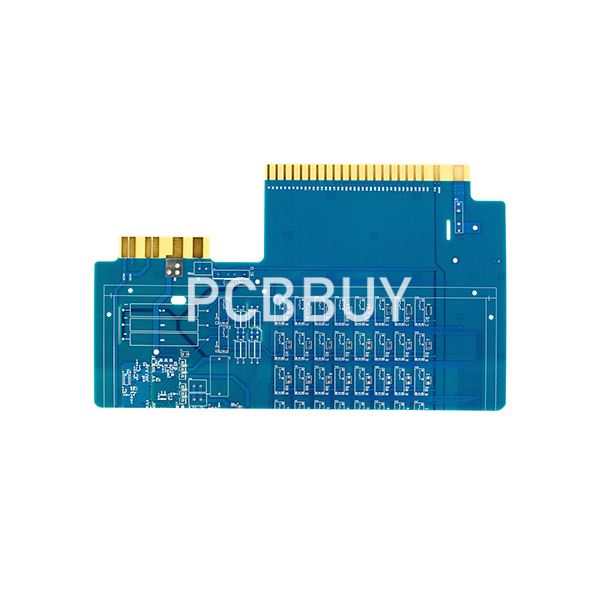

What Are the Components of PCB Mounting?

By:PCBBUY 01/09/2024 14:44

When designing data cabinets, home appliances, office equipment, cable junction boxes or anything that involves electronics, PCB hardware are integral components for your project. This guide will help you understand the different components that can enhance the performance of your printed circuit board.

If you are a PCB beginner and you are going to learn more about the PCB Hardware and how to use them, please check and read the content in this passage.

What is standard PCB mounting?

Pre-formed mounting bosses are among the easiest and fastest ways to mount PCBs in an enclosure. Mounting bosses are molded protrusions from the inner surface of an enclosure that feature countersunk threading on the opposite side to allow screws to be inserted. Simply line up the holes on your PCB with the mounting bosses, insert your mounting boss screws and tighten the screws until secure.

What Are the Components of PCB Mounting?

Apart from this, they add some protection and insulation from electrical transmission, coupled with offering a hold that is more stable and secure. Regarding materials, you have two options to choose from – metal and plastics. With plastics, your PCB will become lighter, and you may prefer the easy installation process that these supports provide.

Mounting options may be different, and include screw locking, reverse locking, snap lock, and adhesive edge locking.

· Snap-Lock: This pushes into a chassis or panel hole. This gives a secure fix that can be easily released.

· Blind hole/press fit: These fins hold some binding holes securely with a unique painted style, which drives with ease into applications.

· Snap-Fit: This pushes quickly into a chassis hole or panel, ensuring that the mounting is efficient and strong. This saves your time when the installation process is on.

· Adhesive base: The adhesive tape gets rid of the use of mounting holes. This provides space and time efficiencies.

How to choose PCB spacers and standoffs?

Spacers and standoffs are a common standard for assembling circuit boards, gears, panels, doors, and other electronic components.

One of the most familiar uses of standoffs and spacers is in computing. Motherboard standoffs are almost always inserted between a PCB and the computer case or chassis. This helps to avoid short circuits (shorting) caused by motherboard traces coming into contact with other metallic parts or surfaces. It also aids cooling by enabling increased airflow around the motherboard and its mounted components.

Spacers are also widely used in various other applications, particularly mounting hardware. They help to achieve more precise positioning of screws and bolts, with adequate gaps left for airflow and cabling. Some bolt spacers also serve to make certain screw-in connections more robust.

There are various types of spacers and standoffs available to order online. They are generally cheap to buy and simple to use, provided you choose the right kind for your intended application.

When selecting these fasteners for a particular job, there are four main factors to consider:

· Spacer or standoff shape (usually round or hex, sometimes square)

· Body diameter (outer width)

· Body length

· Hole clearance width or thread size (inner diameter)

For standoffs, you will also need to bear in mind the length and thread size of the threaded section, as well as the gender of the threading at each end. In the following sections, we will briefly outline some of the basic options for standoff spacer shapes, sizes and materials.

What is LED mounting PCB hardware?

Components of LED like LED spacer mounts restrict movement and position your LED lights. These spacers offer more height conformity, rigidity, and stability. This stability and rigidity ensures that the manufacturing process comes easier. Also, it is important when servicing the board, or whenever there is a need to repair the PCB, as well as other parts.

Some other critical components are the LED holders and mounts. The LED light mount usually features holes that pass the leads. After this the LED is then soldered to the PCB. Since, there may be differences in through hole LED sizes, the LED spacer you are using must possess the correct number of holes. This will help in taking the leads attached.

When handling applications where the mounting of the LED is not done on the PCB directly, then you must use a LED lens holder. You may also require an LED light pipe. This helps in the transmission of light from the PCBs LED mounting. The light pipe technology of LED translates to great visual performance, delivering uniform lighting. Also, it reduces glare and shadows significantly. They also come with another great advantage, which is their ease while installing them.

Industry Category