What Are the Considerations of PCB Annular Ring Calculator?

By:PCBBUY 01/22/2024 16:50

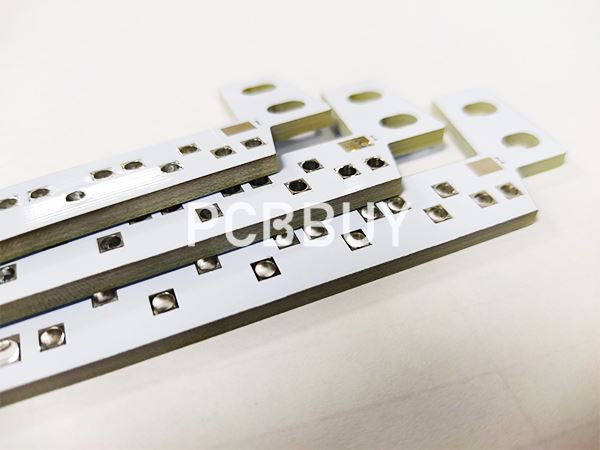

A perfect annular ring will be created by drilling right into the center of the via pad. However, the annular ring may not be in the center because the drilling accuracy depends on the drilling machine used by the PCB manufacturer. There are several drill issues with the annular ring:

In this passage, we will tell you everything about annular ring used for PCB. If you are looking for more information about annular ring used for PCB, please check and read the content below for more.

What Are the Considerations of PCB Annular Ring Calculator?

Different fabrication houses will undoubtedly use varied and differing manufacturing technologies and equipment. Average performance houses may offer design specifications allowing a 10mil minimum annular ring. High performance houses may be able to reduce that figure down to 5mil. If pad and via holes are laser-drilled, as opposed to mechanically drilled, then the value for the minimum annular ring may be reduced further still.

The class of board you are designing will also play a part in the value required for the minimum annular ring. For example, if your design is of IPC Class 3 standard, which refers to high reliability electronics products, the required minimum annular ring is 2mil. If you do have to reduce the annular ring below the accepted standard of the fabrication house, try to limit the usage of such affected pads and vias. The more pads and vias on the board that use such annular ring specifications, the more chance there is of a board failing during the fabrication process.

How to calculate annular ring?

To find an annular ring’s width, you need to use this formula: (pad diameter – via diameter) ÷ 2.

If the diameter of the pad is 25 mils (0.50mm) and the hole/via is 15 mils (0.38mm) then your equation will look like this:

(25 - 15) ÷ 2 = 5 mils

(0.50 – 0.38) ÷ 2 = 0.06mm.

Let us look at further real-world examples. That will include the annular ring's width for standard vias, micro via, and component holes.

Standard Via

Generally, a standard via will feature a hole with a diameter of 0.20mm (7.87 mils). On a 0.40mm (15.74 mils) pad, your final equations will look like this:

(0.40mm – 0.20mm) ÷ 2 = 0.10mm

(15.74 mils – 7.87 mils) ÷ 2 = 3.93 mils

Microvia

Micro vias are typically smaller than your standard holes. They will have a hole diameter of 0.10mm (3.93 mils). On a pad with a diameter of 0.30mm(11.82mm), your equation will look like this:

(0.30mm – 0.10mm) ÷ 2 = 0.10mm

(11.82 mils – 3.93 mils) ÷ 2 = 3.93 mils

Component Hole

As we discussed earlier, component holes tend to be larger than average vias. On a pad with a 1.20mm (47.24 mils) diameter and a 0.80mm (31.50 mils) hole, your equation will look like this:

(1.20mm – 0.80mm) ÷ 2 = 0.20mm

(47.24 mils – 31.50 mils) ÷ 2 = 7,87 mils

What is the application of PCB annular ring?

Annular rings are integral elements of a PCB as they create room for solid electrical connections on a board. Without these rings, you will be unable to create reliable connections on your PCB. Issues related to annular rings are problematic and significantly affect the trace continuity and the functionality of the entire board.

Unfortunately, some designers ignore the importance of annular rings by creating distorted shapes. When designing annular rings, you should be accurate to avoid drilling off the mark. By doing so, you will eliminate the annular ring tangency.

Industry Category