What Are the Considerations of to Be Aware of Large PCB Manufacturing?

By:PCBBUY 09/07/2023 16:39

Working in the yard can be satisfying, but renovations can quickly become overwhelming. Last spring, I started renovating a small corner of my yard but expanding the renovation to the entire yard was unfeasible for one person. What had begun as a curiosity and relatively simple gardening project, quickly swelled to a scale that was unfeasible without having my backyard looking like an excavation site for several months. So, I hired local landscapers to design my yard.

Looking for a contract manufacturer to build a large PCB prototype board is a similar scenario. It can be overwhelming to consider every angle of what needs to be done to build your board on time and within budget. A successful build will arise from determining the manufacturing capabilities and experience of a CM. Thus, it’s important to choose the right CM for a large PCB project and ensure that your prototype board is built correctly.

When Design Becomes a Large PCB

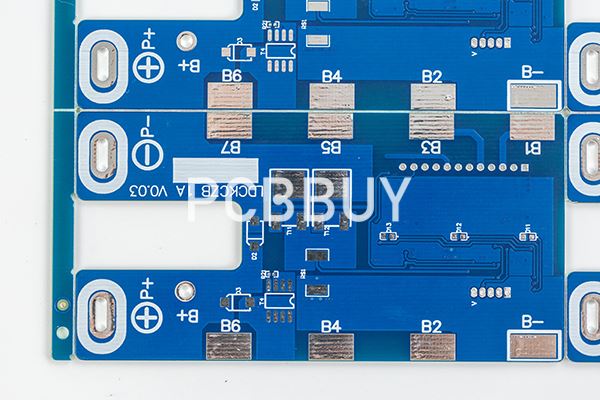

First of all, consider what defines a “large” board: a circuit board that is more than 12 inches wide is large for manufacturing purposes and carries extra requirements. Any layout that is 20 inches long in any dimension would also qualify as a large board. Boards 30 inches wide have reached the limitations of the automated surface mount technology assembly systems. Anything wider will require alternative manufacturing methods, becoming significant cost adders.

The layer count and thickness of the board can also impact the manufacture of a large circuit board. These boards are often used as a backplane, typically requiring many layers. Additionally, these boards usually have many connectors and often include thick power and ground planes. Both of these factors can have an impact on the assembly difficulty.

Considerations to Be Aware of When Manufacturing a Large Circuit Board

Manufacturing a large PCB can bring challenges that a regular-size wouldn’t have to contend with. Here are some areas that might be affected by a large board:

Quick-turn fabrication: Not all fabrication vendors are set up for quick-turn processes. PCB technology, such as high-speed design, impedance control copper thicknesses, and the volume of copper for traces, can slow down the quick-turn fabrication of a board. These same factors can further slow down the production of the board when it is larger than industry standards.

High-layer-count fabrication: PCB fabricators are qualified by CMs based on their fabrication capabilities for circuit board layer counts. Typical qualifications are two to four layers, six to 10 layers, and 12 and above layers. The higher the layer count, the more specialized the supplier must be, which could also slow the fabrication of a large PCB.

Price: PCBs are built on panels, and production charges are, in part, calculated on a price-per-panel basis. The more PCBs fabricated in a panel, the lower the unit cost. The reverse is also true. As large boards don’t fit on traditional panel sizes, the price per unit increases.

Thermal impact: The thickness and number of power and ground planes in a larger board can effectively sink a greater heat. The more metal on the board, the more heat and solder materials will be required. This scenario could cause the solder reflow profile optimization to take longer than normal to define.

Numerous connectors: With multiple connectors on a backplane, more effort in creating and working with the test fixture will be required. Typically, all connector pins must be contacted by the test fixture to test and validate the PCB fabrication and assembly processes. Many connector pins on the backplane can lead to longer test times.

All of these situations can be easily handled by a CM that is experienced with working with large boards. When choosing a CM to build a large prototype board, there are a few qualifications that should be at the top of any list.

Industry Category