What Are the Features of Turnkey PCB Assembly?

By:PCBBUY 03/08/2024 16:53

Circuit board assembly relies on the latest PCB manufacturing technologies such as solder reflow ovens, optical inspection equipment, and trained professionals to operate them. These tools and processes are usually too expensive for electronics manufacturers to own and operate, so OEMs can save a lot of money by using the services of a turnkey PCB assembly shop instead. In addition to the cost savings, there are other benefits to using a turnkey PCB assembly provider.

Do you know the meaning of Turnkey PCB? Do you know the whole process of Turnkey PCB? If you are searching for more information about Turnkey PCB, please check and read the content below for professional knowledge.

What Are the Features of Turnkey PCB Assembly?

There are numerous stages that go into the making of PCB assemblies through turnkey manufacturing:

· Sourcing parts

· Design assistance

· Assembly

· Testing

· Prototyping

· Obsolescence management

· Aftermarket services

PCB turnkey solutions are those that incorporate all of these stages into a single electronics contract manufacturing service. The world calls it “turnkey” because it arrives at your door ready to be turned on and used. You shouldn’t need to worry about whether all the pieces will work together or that the part will not function as intended.

PCB assembly services that offer full turnkey solutions will make certain that your product does what you said it should.

Electronic manufacturing services companies that claim to offer turnkey solutions should have any and all capabilities that help your product come out correctly.

What is the process of turnkey PCB assembly?

You must be wondering what the turnkey PCB assembly process exactly is. Let’s see what are the steps involved in the turnkey PCB assembly.

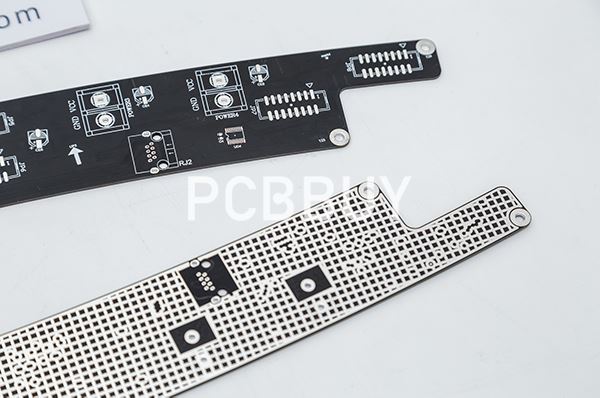

Step 1: PCB Manufacturing

The first step starts when the client provides their circuit’s Gerber file. If you don’t have one, you can send the schematic and tell that what exactly do you have in your mind. They will create the Gerber file and start working on the PCB manufacturing process.

Step 2: Sourcing of Electronic Components

It is essential that the electronic components present on the PCB are of the best quality. There are many electronic components available in the market which claim to be genuine but bur out in a short period of time. Each component is checked for its reliability and then it is soldered on the printed circuit board.

Step 3: PCB Assembly and PCBA Tests

Once the circuit board is fabricated and the electronic components are sorted, the process of soldering starts. The right soldering technique together with high-quality solder paste and SMT stencils is crucial for high quality and fully functional PCB.

What are the benefits of turnkey PCB assembly?

Circuit board assembly relies on the latest PCB manufacturing technologies such as solder reflow ovens, optical inspection equipment, and trained professionals to operate them. These tools and processes are usually too expensive for electronics manufacturers to own and operate, so OEMs can save a lot of money by using the services of a turnkey PCB assembly shop instead. In addition to the cost savings, there are other benefits to using a turnkey PCB assembly provider.

Project Management

The turnkey assembly operation is a process that is managed by the PCB contract manufacturer saving the OEM from having to oversee the board building operation. The OEM can reallocate resources to other tasks because there’s no need to manage all of the different manufacturing areas like engineering, parts procurement, assembly, and test.

Additional Resources

OEMs will occasionally have times where an extra amount of work exceeds the capacity of their in-house engineering resources. Instead of bringing in temporary staff, the PCB CM engineers can provide the necessary resources to get the job done.

Design Focus

The PCB CM’s engineering resources can take on capturing schematics, refining the PCB layout, and generating documentation for a new circuit board build. With these tasks eliminated, the customer’s design engineers are free to focus on the design rather than the paperwork.

Ultimately a contract manufacturer that offers turnkey PCB assembly will provide a more efficient and cost-effective method to build circuit boards. With their staff, equipment, and processes already in place, the PCB CM can immediately respond to customer’s needs and produce high-quality circuit boards ready to be put into service.

Industry Category