What Are the Main Effective Tips of PCB Components Assembly Process?

By:PCBBUY 08/17/2022 15:51

Are you going to learn more about PCB components assembly? We will provide all the details about PCB components assembly please check and read the passage below for more professional knowledge.

What are the technologies of PCB components assembly?

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place robots.

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

What are the types of PCB components?

What is Resistor?

Resistors are one of the most commonly used components in PCBs and is a passive electrical component whose function is to introduce resistance to the flow of electric current in an electrical circuit to limit the current. Their function is to resist the flow of current by dissipating electric power as heat. They come in a multitude of different types made of a range of different materials but the classic resistor most familiar to the hobbyist is the ‘axial’ style resistors with leads on both long ends and the body inscribed with colored rings. These rings are a code that indicates their resistance value.

What is Capacitor?

The Capacitor is a passive electrical component, whose function is to store electrical energy and deliver it to the circuit when needed. The function of capacitors is to temporarily hold electric charge, and release it whenever more power is needed elsewhere in the circuit. Typically, it does this by collecting opposite charges on two conductive layers separated by an insulating, or dielectric, material. Capacitors are often categorized according to the conductor or dielectric material, which gives rise to many types with varying characteristics from high capacitance electrolytic capacitors, diverse polymer capacitors to the more stable ceramic disc capacitors. Capacitors fall into two categories: Polarized and non-polarized.

What is Inductor?

The Inductors is a passive two-terminal electrical component that stores magnetic energy when an electric current is passed through it. It’s an insulated wire wound into a coil around a core of some material (air, iron, powdered iron, or ferrite material) in a spiral form. The simplest inductor is a coil of wire. The greater the number of windings, the greater the magnetic field and therefore inductance. This serves to amplify the magnetic field substantially and therefore, the stored energy.

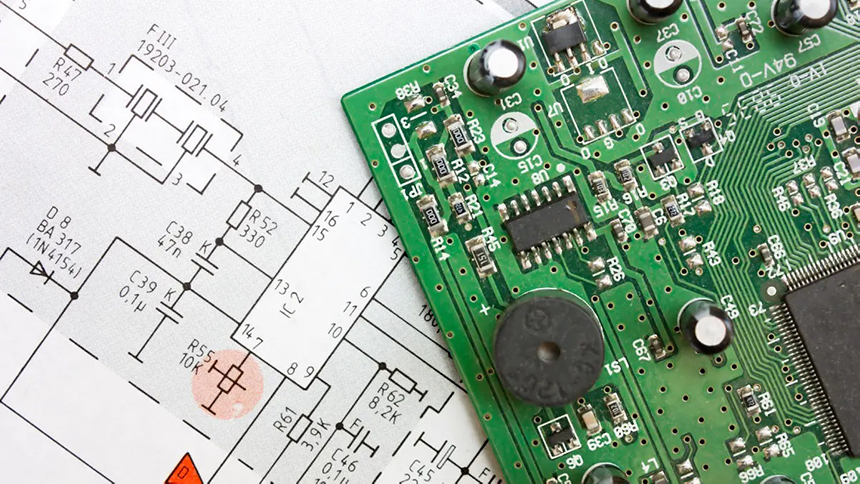

What is the process of PCB components assembly?

It is always prudent to design printed circuit boards with PCB assembly in mind. However, this concept proves a commonly misunderstood concept. It is common knowledge that the Assembly of components can happen via one or both through-hole and surface-mount technology approaches. You have to identify the appropriate approach in the design phase to ensure that you approach the right PCB assembly partner for your needs.

PCB Assembly with Through-Hole Electronic Components

It is an assembly process that features electronic components that possess lead protrusions getting fixed through small holes within the PCB before soldering. The soldering process can either entail hand soldering or wave soldering. Wave soldering entails a printed circuit board assembly process where there is insertion of the solder (solder bar) in a high-temp bath. As it remains in the molten form inside the bath, it forms waves at high temperatures. However, the temperature ranges with the type of solder used.

The process entails the insertion of components, application of flux, preheating before wave soldering. It then undergoes cleaning and testing to identify any solder joint flaws or faults. Conversely, hand soldering happens through manufacturing units devoid of any excessive workloads or repairs. It happens by hand and mostly post- the wave soldering process.

PCB Assembly with Surface-Mount Electronic Components

It is an assembly approach that uses surface-mount technology in assembling SMD electronic components. Surface mount devices do not have legs or leads and thus get mounted on the circuit board’s surface. It uses a separate set of electronic components, equipment, and other solder materials in the assembly process from the THT approach.

Industry Category