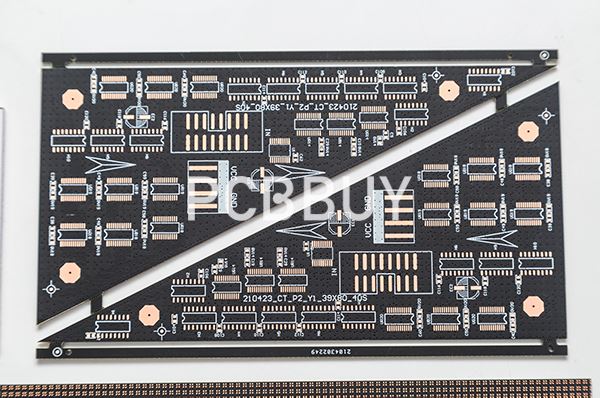

What Are the Main Features about PCB Substrate?

By:PCBBUY 03/06/2024 15:15

Your substrate selection is no longer limited to FR4, but you should not make the decision of PCB laminate selection lightly. You should first understand how different material properties affect your PCB and choose a laminate that satisfies your operational requirements accordingly. Don’t just listen to marketing speak from laminate manufacturers; take time to understand each of the substrate material properties and how they affect your PCB quote.

If you are searching for the professional knowledge of PCB material mechanical properties, please check and read the content below for more information.

What are the types of PCB substrate?

Once upon a time, the choice in radio frequency/microwave circuit-board materials was a simple choice of:

· Hard, or rigid circuit material

· Soft, or flexible circuit material

You now have more to choose from. With the boom in electronics, circuit materials are now available for specific applications, such as antennas, or even frequency ranges, e.g. millimeter-wave frequencies.

Still, the base substrate for most PCB materials tends to fall into the same categories as before: hard/rigid or soft/flexible.

What Are the Main Features about PCB Substrate?

Mechanical properties of copper tube and the matrix resin adhesion (peel strength) and mechanical strength (e.g., flexural strength), impact resistance, dimensional stability, flexibility, heat distortion resistance, the base processing (punching, drilling performance) and the like.

Electrical characteristics of insulation resistance, resistance to the electric field strength (voltage resistance), the dielectric properties (dielectric constant, dielectric loss factor Wei, etc.), ion migration resistance, resistance to leakage and trace quality copper resistance.

The physical characteristics of thermal expansion coefficient (CTE), flammability (flame retardant), a base that is generally warped by the degree of flatness (bow and twist), moisture absorption.

Chemical properties. Heat resistance, breaking glass transition temperature (Tg), weldability, resistance to chemicals capacity (acid, alkali and solvent resistance) and the like.

Environmental resistance. Fungus resistance, moisture resistance, cooking, resistance to thermal shock properties.

Green living substrates suitable for RoHS Directive inauspicious lead and other harmful substances halogen chapter though - .. Some high reliability requirements of the product is not currently required · main lead solder must be used, but from the perspective of environmental protection jealous consideration. When conditions are ripe to make the use of non-polluting or less polluting materials.

What are the PCB material mechanical properties?

Before tackling the impact of PCB material properties on your board’s manufacture, we need to know what they are. The significant properties may be classified as mechanical, electrical, thermal or chemical.

Mechanical Properties

Bending (Flexural) Strength

The ability of your board to resist deformation or breakage when under bending stress. Standards for rigid, flex and rigid-flex must be adhered to according to IPC-6013C.

Time to Delamination

A measure of how long a PCB’s layers will remain attached when exposed to temperature changes or moisture.

Density (g/cm3)

The amount of mass per volume for a dielectric.

Peel Strength

The ability of copper layers and dielectrics to remain bonded under thermal and chemical stress.

Electrical Properties

Dielectric Constant, dk

Affects the signal integrity and impedance of a PCB material. Should be constant over a broad range of frequencies for high-speed applications.

Relative Permittivity, Er

Referred to as relative dk.

Surface Resistivity, 𝛒S (Ω-m)

A measure of a dielectric material’s surface resistance to the flow of electricity. Susceptible to change with temperature and moisture. Should be high to facilitate good signal integrity.

Volume Resistivity, 𝛒 (Ω/m2)

Measure of a dielectric’s volume resistance. Preferably high to maintain isolation between layers.

Industry Category