What Are the Main Reasons for Choosing Green PCB?

By:PCBBUY 10/28/2024 16:11

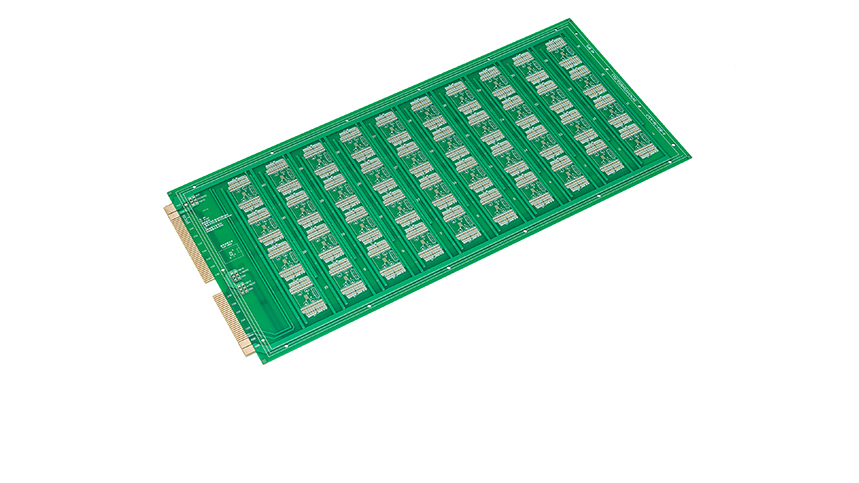

In the realm of electronics, Printed Circuit Boards (PCBs) play a pivotal role by providing a foundation for the electrical connections between components. Among various color options, green PCBs have emerged as a standard choice in the industry. This article delves into the primary reasons for opting for green PCBs, exploring their benefits in performance, cost-effectiveness, aesthetic appeal, and environmental considerations.

What Is the Significance of PCB Color?

1. Aesthetic Appeal

The green color of PCBs is not merely a design choice; it serves several practical purposes. The color is derived from the solder mask, a protective layer applied to the board. Green is a visually appealing hue that helps to standardize PCBs across the industry, making them easily recognizable. Furthermore, the color helps to conceal imperfections and solder marks, contributing to a cleaner and more professional appearance.

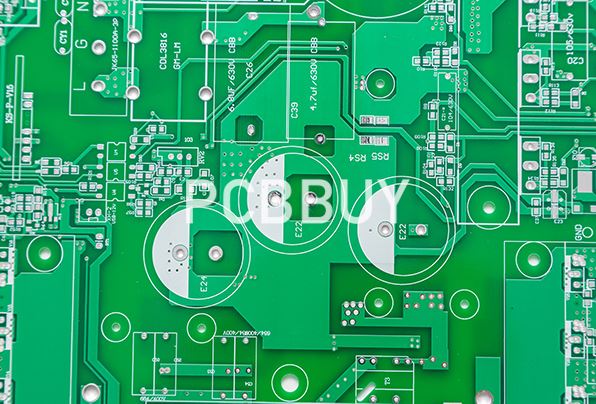

2. Thermal Management

The thermal management properties of PCB materials significantly impact their performance. Green PCBs are often constructed with materials that possess good thermal conductivity. The copper traces, typically coated with a layer of tin-lead or lead-free solder, allow for effective heat dissipation. This is crucial in high-performance applications where excessive heat can lead to component failure.

What Are Performance Benefits of Green PCBs?

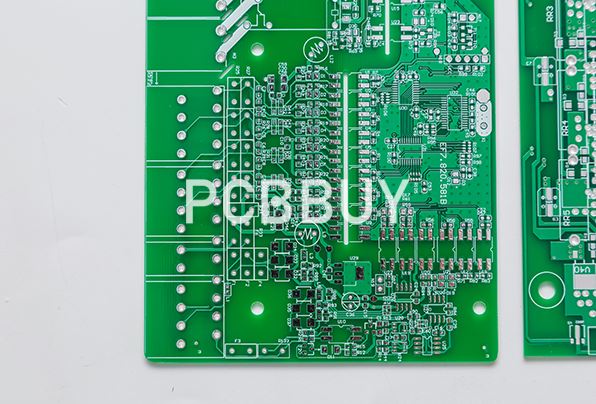

1. Reliability

Reliability is a critical factor in the selection of PCBs. Green PCBs have a long-standing reputation for reliability due to the high-quality materials used in their production. The epoxy resin used for the substrate, combined with the solder mask, provides excellent insulation and resistance to moisture. This is essential for ensuring the longevity of the circuit board in various environments.

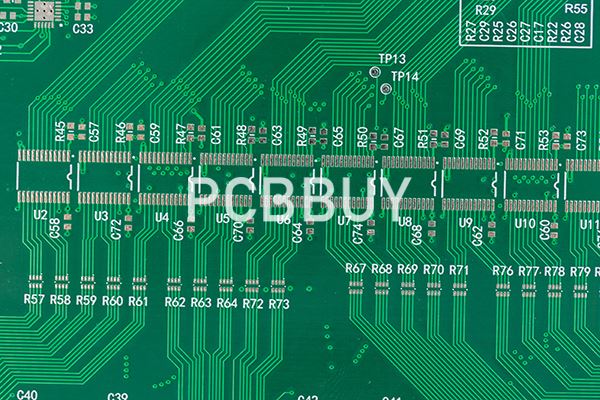

2. Signal Integrity

In high-frequency applications, signal integrity is paramount. Green PCBs typically offer better performance in terms of impedance control and crosstalk reduction. The uniform thickness of the solder mask and copper traces contributes to consistent electrical characteristics across the board, minimizing signal degradation.

What is Cost-Effectiveness of Green PCBs?

1. Manufacturing Efficiency

One of the significant advantages of green PCBs is the efficiency of their manufacturing process. The widespread adoption of green solder masks has led to streamlined production methods. The compatibility of green PCBs with automated assembly lines reduces labor costs and production time, making them an economical choice for manufacturers.

2. Economies of Scale

As green PCBs are the industry standard, they benefit from economies of scale. The availability of materials and components specifically designed for green PCBs leads to reduced costs for manufacturers. This translates to lower prices for consumers, making green PCBs a cost-effective solution for various applications.

What Are the Environmental Considerations?

1. Eco-Friendly Materials

With growing concerns about environmental sustainability, the choice of materials in PCB manufacturing has become increasingly important. Many green PCBs are produced using eco-friendly materials and processes. For example, lead-free solder options are commonly used to minimize environmental impact. Additionally, the production of green PCBs often adheres to stringent environmental regulations, ensuring that harmful substances are reduced or eliminated.

2. Recyclability

The recyclability of PCBs is another factor contributing to the preference for green options. The materials used in green PCBs are often easier to recycle compared to those used in other colored PCBs. This aligns with the global push for sustainable practices in electronics manufacturing and waste management.

What Is the Comparison with Other Colors?

Table 1: Comparison of PCB Colors and Their Characteristics

|

PCB Color |

Aesthetic Appeal |

Thermal Management |

Cost |

Environmental Impact |

|

Green |

High |

Good |

Low |

Low |

|

Red |

Moderate |

Good |

Medium |

Moderate |

|

Blue |

Moderate |

Good |

Medium |

Moderate |

|

Yellow |

Low |

Poor |

High |

High |

Conclusion

The choice of green PCBs is driven by a combination of aesthetic appeal, performance benefits, cost-effectiveness, and environmental considerations. As the electronics industry continues to evolve, green PCBs remain a popular choice for manufacturers seeking reliable, efficient, and eco-friendly solutions. The standardized nature of green PCBs ensures they will continue to play a vital role in the future of electronics.

References

1. Smith, J. (2021). "The Importance of PCB Design." Journal of Electronics, 45(2), 123-135.

2. Jones, R. (2020). "Sustainability in Electronics Manufacturing." Green Technology, 12(4), 56-70.

3. Lee, A., & Wang, B. (2019). "Materials in PCB Manufacturing." International Journal of Materials Science, 37(3), 210-225.

Industry Category