What Are the Main Types of PCB Milling?

By:PCBBUY 03/15/2024 16:28

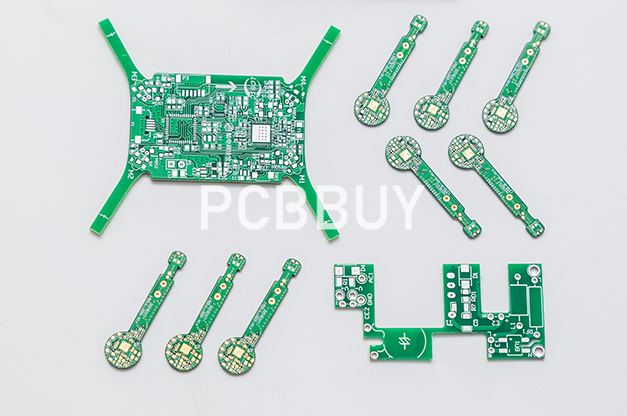

Printed circuit board milling is the process of removing areas of copper from a sheet of printed circuit board material to recreate the pads, signal traces and structures according to patterns from a digital circuit board plan known as a layout file. Similar to the more common and well-known chemical PCB etch process, the PCB milling process is subtractive: material is removed to create the electrical isolation and ground planes required.

However, unlike the chemical etch process, PCB milling is typically a non-chemical process and as such it can be completed in a typical office or lab environment without exposure to hazardous chemicals. High quality circuit boards can be produced using either process. If you are going to search the information of PCB milling, please check and read the content below in this passage for more.

What are the benefits of PCB milling?

Needless to say, PCB milling has advantages for both PCB prototyping and some special PCB designs. And it doesn’t need to fabricate the circuit board with chemicals that may be the biggest advantage.

On one hand, it needs to take time to outsource as creating a prototype. The other one is to make a circuit board in-house. However, there will have some problems with chemicals and disposing thereof using the wet process for in-house production. Although it is difficult to fabricate the high-resolution circuit boards with the wet process, it still needs to drill and finally cut out the circuit board from the base material.

On the other hand, CNC machine prototyping can provide a quick turn PCB fabrication with fast lead time without the need for wet processing. If a CNC machine is already used for drilling, this single machine could carry out both parts of the process, which is milling and cutting. What’s more, a CNC machine is used for drilling, milling, and cutting.

There will be so hard for many circuit boards that are simple for milling to do the process by wet etching and manual drilling afterward in a laboratory environment if you don’t use top of the line systems that usually cost multiple times more than CNC milling machines. However, it is likely for milling to take the place of etching in PCB mass production through the use of CNC is already standard practice for drilling the circuit boards.

What Are the Main Types of PCB Milling?

CNC mills are sometimes classified according to the number of axes on which they can work. Each axis is labeled with a different letter. The X and Y axes, for example, reflect the lateral rotation of the mill’s work piece. The Z-axis represents vertical rotation. The W axis represents the diagonal rotation through the vertical plane. The number of CNC milling machines has three to five axes. To function correctly, more modern mills must be programmed with CAM technology. These sophisticated CNC machines can create forms that are almost difficult to create user manual tooling techniques.

Furthermore, most CNC mills are outfitted with a unique system that supplies fluid to the cutting tool during the manufacturing method. CNC Milling Machines are valuable equipment for commercial and industrial processing. CNC Milling materials may support the aerospace industry, the medical industry, and the electronics industry.

How to determine the parameters of PCB milling?

The tool diameter is the lowest 0.8 mm, the normal diameter 2,0 mm, the customized diameter >=0.8 mm<2.0 mm, but the internal and outside board contours are milled according to client requirements.

Following the client’s requirements, the outside contour maybe 90° and round, but the inside corner of the design has at minimum the milling cutter diameter. Usually, the edge of the rectangle orbits the earth; the matching milling portion should also be perforated at the sides to preserve a precise rectangular area.

The breakaway and contour of PCBs are usually machined. Whereas, certain rules exist:

· Usually, there is no additional frying price.

· With the copper endurance of the circuit board, the danger of harm must be avoided.

· The inner and outside contours of the board should be marked with a channel length of 1μm to avoid problems of measuring and size.

How to guarantee the quality of board through PCB milling?

It is vital to bear in mind that the board’s performance is defined by the visibility and accuracy of the milling and the sharpness of the frames. PCB friction enables prototyping and a unique Pcb layout. A solitary device may be used to conduct the operation necessary to make a prototype board during molding. For seamless operation, the equipment employs conventional Ac power and vacuum cleaner. The physics underlying the frying machine is simple. It’s small and precise. It is easy to manage the equipment through software using instructions delivered. The microcontroller should then monitor constituent location while the friction head moves. This enables to adjustment of the speed of the spindle from 30 000 RPM to 100 000 RPM. Note that the faster the speed of the spinning, the more exact it is.

The PCB Milling Machine uses the phase motor to drive accuracy for the X and Y coordinate mechanism. For coordination in the milling, a specific precision link assembly might be employed. Milling PCBs have several issues, including flatness variances. The rationale is because gravure methods employ optical traps on the copper foil that may be matched to the small bends in the substance used to guarantee that all characteristics are duplicated. However, as you mill, the small fluctuation in height enables con-shaped parts to sink or rise. Therefore, mapping might be essential to assist tune the Z-values in advance.

Industry Category