What Are the Methods of Removing Solder Mask from PCB?

By:PCBBUY 01/23/2024 15:24

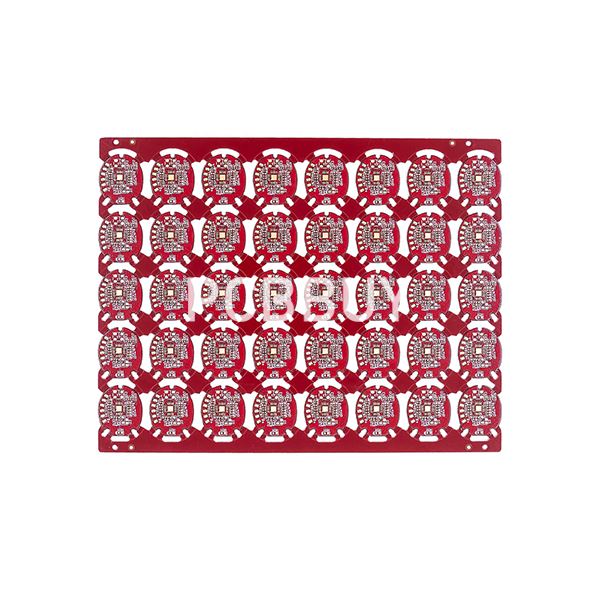

PCBs are green in color which is the color of solder mask green oil. However, with us, you can also get a solder mask in other colors. Choose from options like white, black, blue, yellow, red, and more. Adding in colors gives a little bit more personality. That is why more OEM manufacturers are choosing a color for themselves. It’s how they know it’s a board that is theirs.

Plus, OEM manufacturers also choose colors according to the niche. For instance, those in the artificial intelligence industry choose a red color these days. You use blackboards for projects that require more light reflection. Check and read the content below for removing solder mask from PCB.

What are the types of PCB solder mask?

The solder mask prevents the conductive solder bridging between the various electronic components. Substantially, it stops short circuits. The different PCB solder masks are as below.

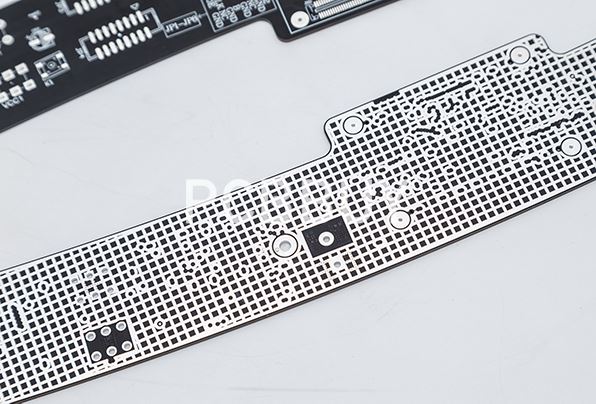

· Top and Bottom-side Masks: An electronics engineer knows the various openings. He knows what gets added through an ink, epoxy or film technique. He can then solder the component pins on the board with the help of identified places. You can also note that the pattern of conductive traces on the top of the circuit board. You call these as top traces. The lower ones are the bottom side masks.

· Epoxy Liquid: If you want to go for a cheap option, go for epoxy liquid. The thermosetting polymer has several applications. Silk screening is a printing technique. It uses a woven mesh for supporting ink-blocking patterns. The mesh can create an open area for the transfer of ink. Thermal curing is a part of the final finishing process.

· Liquid Ink Photo-Imageable: We provide the solder mask as ink formulation. You can spray the ink into the PCB. You can then expose the pattern and develop it. The thing to note is that we use the process along with liquid ink formulation. This needs clean surroundings free from contaminants and particles. One can remove the mask after exposing it to UV light. I do this through high-pressure water sprays known as developers.

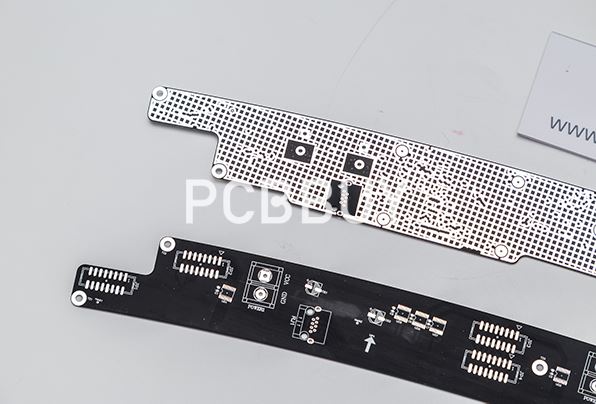

· Dry Film Photo-Imageable: Apply this solder mask with the help of vacuum lamination. After the development, you can create openings and solder the parts to the copper pads. Also, apply tin for protection of the copper circuitry. We then remove the dry film.

What Are the Methods of Removing Solder Mask from PCB?

These factors and others must be evaluated before deciding on the most appropriate removal technique.

Grinding and Scraping

Basic hand grinding.Nothing fancy here, just lots of grunting and groaning. Often the use of a knife, scraper or pick in the hands of a skilled technician is the most controlled technique for removing solder mask from areas where you don't want it.

No special setup is needed but operator fatigue can be a drawback on large projects. Mechanical erasers, like the type a draftsman would use, can speed up the process. This technique is controlled and methodical, most commonly used when removing a thin layer of solder mask. It can be used in conjunction with other removal techniques as a final surface preparation step.

Machining and Milling

Milling machines can deliver the accuracy needed for precise solder mask removal.Would you use a milling machine to remove soldermask? Seems extreme, but can be a very effective and precise technique for removing solder mask. Since sharp cutters will be used, precision depth control is essential. The milling system will need to be fitted with a microscope for visual aid.

Carbide end mills are the most common type of cutter used. Since carbide cutters are so sharp they will tend to pull into the coating and may penetrate into the board surface. Turning the cutter in the opposite direction can be an effective technique for controlling the depth. Operator skill and experience are paramount.

Chemical Stripping

This technique is most effective when removing solder mask from copper planes or soldered surfaces. Masking tapes or other protective materials should be placed on the circuit board surface to isolate the area to be stripped.

The chemical stripper is then applied with a brush or swab. Since the stripper is liquid, it is often difficult to control. The chemical will attack the coating and break it down just like a paint stripper. The most common chemical strippers will contain methlyene chloride, a strong solvent. Not only will methlyene chloride based strippers quickly remove the solder mask, they'll deteriorate the base material if exposed to it for a prolonged period.

Industry Category