What Are the Strategies and Solutions of EOL Component of PCB Assembly?

By:PCBBUY 09/16/2023 15:35

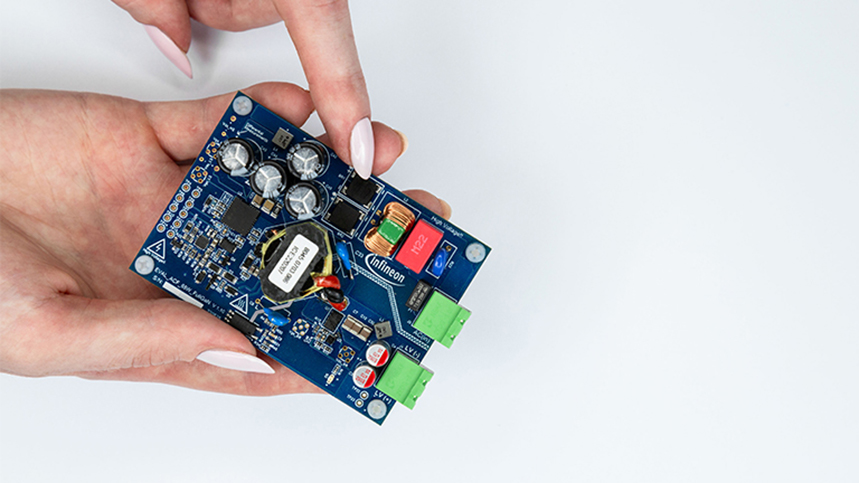

It’s much less fun having to replace PCB components that are no longer being manufactured or in wide circulation for PCB assemblies built by a contract manufacturer. Designers need to know what may be changing with these components far enough in advance so that those changes can be mitigated and implemented with a minimal impact on production. In cases where a component is no longer available, the engineering services of a CM for end-of-life (EOL) components can plan around the obsolescence.

Why Obsolescence?

Suppliers have to balance the needs of existing parts and new products with limited production capabilities. Some components are industry stalwarts and remain in circulation for years if not decades. But others may be revised or replaced due to improvements in material sciences and manufacturing technologies.

Fit

Is there an alternate interfacing technology or orientation that better suits the needs of users? This could be an entirely new connector format/standard implementation.

Form

Can the package be resized – specifically, reduced – without a noticeable deviation in performance? Most notably, this increases the available routing space of the board, but other board concerns, such as shock/vibration resistance, can also improve.

Function

Were features added, removed, or otherwise changed? Improved component functionality drives adoption by affording new options to designers. It’s worthwhile to underscore that obsolescence can also be driven by economic factors like component manufacturers switching production to chips with higher margins. This has been the case for some during the component shortages arising from partial or complete shutdowns during the COVID-19 pandemic responses.

Expect and Prepare for EOL Components

There are numerous changes the components used to produce a PCB may undergo. In some circumstances, a component could have its specifications updated for either performance or even physical size.

While changes are usually minor, they could impact a design, especially when components are in short supply, no supply, or prices have dramatically changed. The component change that will have the greatest impact on designs will be for EOL parts. In these cases, component vendors sometimes replace an older component with a newer version or stop production altogether if demand is nonexistent. Or, take the ongoing shortage resulting from manufacturing shutdown and below-capacity operations; this has resulted in a steep climb of prices and lead times for some of the most fundamental components.

As a design engineer, product development takes precedence over procurement. When there’s barely enough time to find the parts needed, let alone plan out their expected lifecycles and lead times or quality are likely to suffer. Instead, component engineers working for a CM can help by monitoring the status of the components on boards and alerting designers to potential problems on the horizon.

Tracking the Manufacturing Status of Components

Component engineers monitor the obsolescence notifications from part manufacturers and distributors. They also are looking for changes in components for availability and pricing and have the latest information on part specifications. By maintaining databases on all of this information, the engineers have a complete picture of the life cycles of the components active within production.

Quality CMs should have component engineers who are experts at predicting and reacting to lifecycle changes of the parts used in extant designs. They also perform life cycle analysis of all the materials used in the production of your board to assign ratings based upon their current and future availability:

Healthy lifecycle

No design adjustments are necessary or expected.

Caution

The component or product line is being prepped for replacement; new part manufacturing will eventually cease.

EOL

The component is no longer being produced, nor are there plans to reintroduce it.

This information is vital to planning the production schedules of boards accurately. A component that is not recommended for new designs or that is EOL could cause several unforeseen consequences (including completely halting the production of your product) if the assembly cannot procure. Then the design team must prepare a new revision. Therefore, the most critical step in planning for EOL components is a CM partnership with qualified component engineers on staff who can identify these issues far before they cause manufacturing delays

Industry Category