Working Principles of Floor Robot PCB: A Comprehensive Guide

By:PCBBUY 03/17/2023 09:31

Floor cleaning robots, often referred to as sweeping robots, intelligent vacuum cleaners, or robot vacuum cleaners, have revolutionized modern home cleaning. Behind their intelligent functions lies a core component that ensures precision and efficiency—the floor robot PCB (Printed Circuit Board). Understanding the working principles of floor robot PCB can offer deep insights into how these autonomous machines operate seamlessly in daily life.

What Is a Floor Robot PCB?

A sweeping robot is an intelligent household appliance capable of automatically cleaning floors using sensors, AI algorithms, and a robust control system. The PCB in floor robots functions as the central nervous system, integrating input from sensors and executing complex cleaning algorithms.

Modern floor robots typically perform vacuuming, sweeping, and even scrubbing. These actions are made possible by motors, sensors, and components connected through a customized, high-reliability robot PCB layout.

Working Principles of Floor Robot PCB

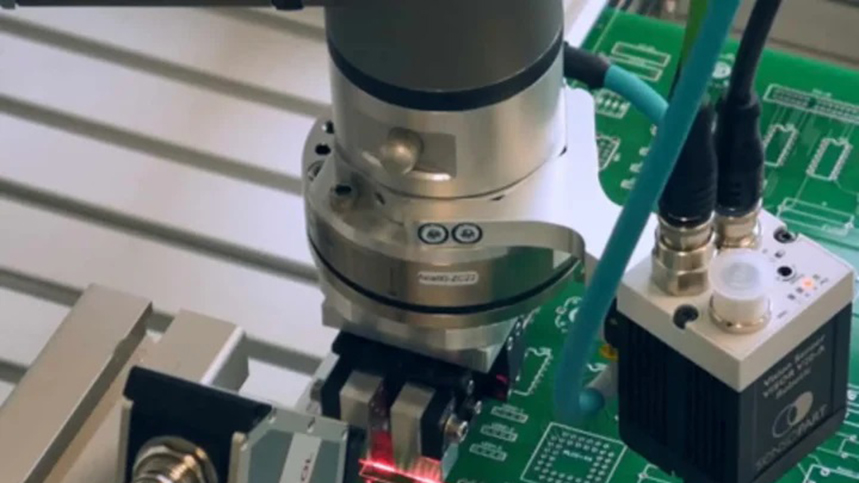

1. Sensor Integration and Signal Processing

At the heart of the floor robot PCB are microcontrollers and embedded chips responsible for real-time data collection. Sensors on the robot—such as infrared, laser (LiDAR), and gyroscopic modules—send signals to the PCB PRODUCT, which then processes this data to detect:

-

Obstacles (walls, furniture)

-

Drop-offs (stairs)

-

Dirt-heavy areas

-

Map boundaries

The PCB enables real-time response, adjusting the robot's path and motor output based on sensor data.

2. Motor and Power Control

The PCB controls brush motors, wheel motors, and suction fans through dedicated power circuits. By using PWM (Pulse Width Modulation), the board adjusts the rotation speed and suction power according to floor type or dirt level.

Additionally, motor driver ICs and MOSFETs on the PCB help manage the energy consumption and motor protection, ensuring long-term durability.

3. Navigation and Path Planning

Modern floor cleaning robots use advanced algorithms for path planning, such as:

-

Random path (earlier models)

-

Zigzag or linear path

-

Smart mapping with SLAM (Simultaneous Localization and Mapping)

These navigation commands are processed on the floor robot control PCB, which integrates memory units and computing power to make real-time decisions.

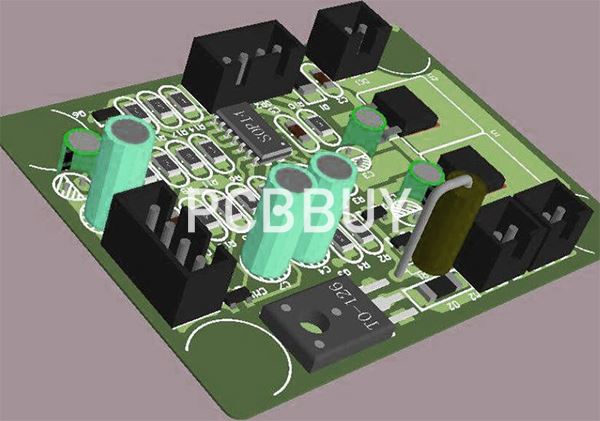

Floor Robot PCB: Component Overview

To better understand the working principles of floor robot PCB, it's essential to explore its key components:

|

Component |

Function |

|

Microcontroller (MCU) |

Processes sensor data, controls motors, executes algorithms |

|

Power Management Unit |

Regulates battery power to different parts of the robot |

|

Sensor Interfaces |

Connects and communicates with IR, LiDAR, cliff sensors |

|

Motor Driver Circuit |

Controls wheel, brush, and fan motors |

|

Communication Module |

Enables remote control or app connectivity |

|

Battery Management System (BMS) |

Ensures safe charging and discharging |

Automated Charging and Scheduling

One essential feature controlled by the robot vacuum PCB is automated charging. The robot can return to its charging dock using infrared or radio-frequency signals. This intelligent navigation and docking mechanism relies on the precise control of movement and sensor data through the PCB.

Furthermore, scheduling cleaning times is made possible by RTC (real-time clock) modules and timer circuits embedded in the PCB, giving users full automation and convenience.

Common Cleaning Modes Enabled by PCB Logic

Depending on the brand and model, sweeping robots offer different cleaning patterns, including:

-

Edge cleaning: Follows along walls and baseboards

-

Spot cleaning: Cleans a localized area intensively

-

Zigzag/Parallel path: Optimized coverage with minimal redundancy

All of these behaviors are executed through software logic running on the PCB and controlled via a remote or app interface.

Types of Batteries and Charging Circuits

Most floor robots use either NiMH or lithium-ion batteries. The floor robot PCB integrates the charging management system, including:

-

Battery protection (overcharge/discharge)

-

Charging ICs

-

Voltage and current sensors

This ensures safe and efficient power usage throughout the robot’s operating cycle.

Conclusion

Understanding the working principles of floor robot PCB unveils how this intricate circuit board is at the core of intelligent floor cleaning. From controlling motors and sensors to handling navigation and power management, the PCB orchestrates every function of the robot.

As floor robot technology evolves, so does the complexity and integration level of the PCBs within them. For developers, engineers, and tech-savvy users, learning the structure and function of robot PCB boards offers valuable insight into modern automation in home appliances.

Industry Category