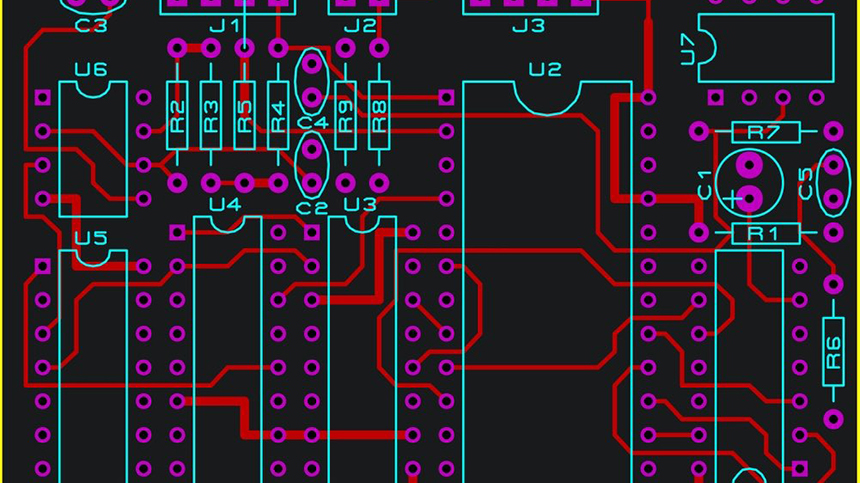

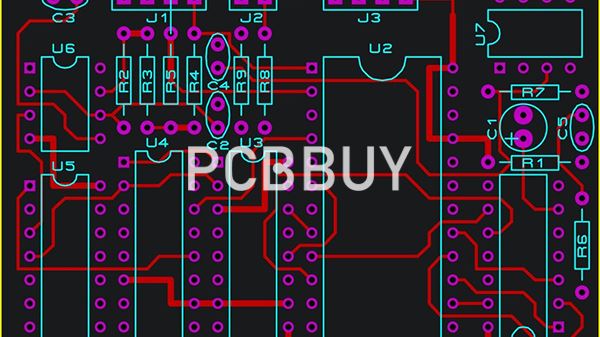

What Does High Density Mean in PCB Layout Process?

By:PCBBUY 11/13/2021 09:59

A HDI PCB is usually found in complex electronic devices that demand excellent performance while conserving space. Applications include mobile /cellular phones, touch-screen devices, laptop computers, digital cameras, 4/5G network communications, and military applications such as avionics and smart munitions.

Are you searching for more information about high density PCB layout? If you are curious about the details knowledge of high density PCB layout, please check and read the content below in this passage to learn the information.

What are the advantages of high density PCB?

Some benefits of these specific printed circuit boards include:

· These PCBs are extremely compact. Considering that HDI PCBs have a higher wiring capacity, they are one of the best options for engineers looking for the smallest circuit board with the largest output. HDI capacity makes it easier to turn a 10 layered PCB into a four or five layered one, which is great for those looking for smaller boards without skimping on quality. Since most consumers prefer small devices, this can be a huge design advantage.

· The ability to place more components on one side. These HDI PCBs utilize blind and buried vias, and Via-in-Pad technology, as methods of placing components closer together, which results in faster signal transmission. Making it an ideal technology for RF circuits.

· Laser drill technology makes PCBs into advanced electronic circuits. This manufacturing technique allows for smaller holes to be used and gives the board higher heat resistance.

What is the cost effect of high density PCB?

While some consumer products shrink down in size, quality remains the most important factor for the consumer second to price. Using HDI technology during design, it is possible to reduce an 8 layer through-hole PCB to a 4 layer HDI microvia technology packed PCB. The wiring capabilities of a well-designed HDI 4 layer PCB can achieve the same or better functions as that of a standard 8 layer PCB.

Although the microvia process increases the cost of the HDI PCB, the proper design and reduction in layer count reduces cost in material square inches and layer count more significantly.

How to choose the material of high density PCB?

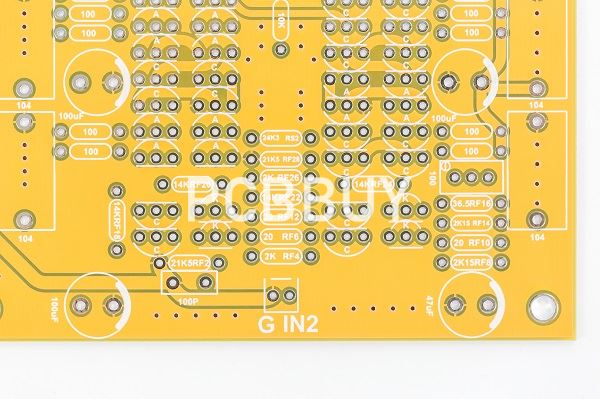

Advanced multilayer technology allows for designers to sequentially add additional pairs of layers to form a multilayer PCB. The use of a laser drill to produce holes in the internal layers allows for plating, imaging and etching prior to pressing. This added process is known as sequential build up. SBU fabrication uses solid filled vias allowing for better thermal management, a stronger inter connect and increasing the board's reliability.

Resin coated copper was developed specifically to aide with poor hole quality, longer drill times and to allow for thinner PCBs. RCC has an ultra-low profile and ultra-thin copper foil that is anchored with minuscule nodules to the surface. This material is chemically treated and primed for the thinnest and finest line and spacing technology.

What are the capabilities of high density PCB?

HDI PCB manufacturing requires an advanced level of technical expertise and the latest state-of-the-art equipment for exacting precision.

Advanced Circuits' multiple U.S. based facilities offer solutions for low-volume/high-mix PCB manufacturing on a quickturn basis, as well as production quantities and high-tech capabilities for advanced builds with demanding requirements for aerospace, defense, medical, and commercial applications. Capabilities include:

· Laser Drilled Microvias

· Sequential Lamination

· Stacked Microvias

· Blind & Buried Vias

· Via-in-Pad

· Laser Direct Imaging

· .00275" Trace/Space

· Fine Pitch (Down to .3mm)

Why to choose the high density PCB?

Because of their light weight, reliable performance, and small size, HDI boards are especially appealing for wearable, mobile, and handheld electronics. Combined with the geometry of a high-density design, these stronger, smaller components and additional transistors elevate the function of a PCB and the end-product it is used for.

With components in closer proximity to one another, electrical signals take less time to travel. The high-density design of HDI boards reduces the rise time for the signal and the inductance, thus limiting the effects on nearby pins and leads. Additional transistors support not only increased functionality, but also heightened performance.

Concentrating on HDI design diminishes the time and cost of cultivating prototypes, shortening leads times, and allowing for much larger profit margins.

Industry Category