What Does IPC Stand for PCB for Manufacturing Process?

By:PCBBUY 11/20/2021 09:17

IPC is the official name of the association which produces PCB-related standards. The association was formerly called the Institute for Printed Circuits (hence the acronym "IPC"), but is presently called the Association Connecting Electronics Industries—even though it retains the IPC moniker.

If you are curious about the knowledge of IPC for PCB, please check and read the passage for more about the information. Please follow us and get your useful information in this passage.

What is the basic information of IPC for PCB?

IPC has its headquarters in Bannockburn, Illinois, and has other offices around the United States and the world, including in India, China, Sweden and Russia. The American National Standards Institute (ANSI) has accredited IPC as a standard-developing organization. What are the IPC standards? They are the most widely recognized acceptability codes in the electronics industry. The organization publishes standards for nearly every phase of the electronic product development cycle, including design, purchasing, assembly, packaging and more.

IPC currently has more than 300 active standards and more than 1,000 standards in its resource library. Electronic designers all around the world use these standards for everything from generic reference designs to more customized blueprints. Committees of volunteers from across the electronics industry draft, edit and vote on IPC standards. More than 3,000 industry professionals across the globe participate in this process. Committees can include people from around the world, as members can participate via in-person meetings, teleconference and email.

What are the applications of IPC for PCB?

IPC, itself, is an international industry association consisting of more than 4,000 member companies that make, use, specify, and design PCBs and assemblies, including:

· Advanced microelectronics

· Aerospace and military

· Automotive

· Computer

· Industrial equipment

· Medical equipment and devices

· Telecommunications industry

What is the purpose of IPC component spacing?

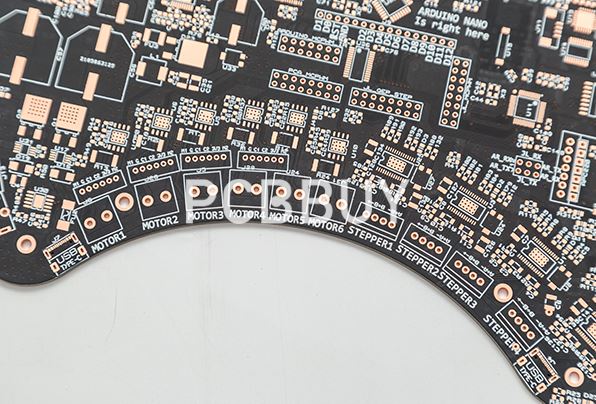

The IPC component spacing guidelines are a third check on these potential physical problems. As long as designers follow the spacing guidelines, there should not be physical overlaps of components except in special circumstances that require additional engineering and development.

Component spacing guidelines also manage negative space—the places where components are not present. Negative space on a PCB can be just as important as the regions where components exist, and this space is particularly important when preventing electrical interference. If conductive traces or circuits are too close together, unintentional connections may form between them as electrons jump between circuits.

These unexpected connections reduce the strength of signals traveling through some regions of the PCB and can increase the amount of power flowing through other areas. Reductions in power can cause shorts or failures, while surges in power can cause physical damage or overloads.

What is the content of IPC standards?

Direct from IPC, the goals of adherence to their standards include:

· To provide a standardized set of industry developed, recognized, approved and traceable training programs to enhance understanding and appropriate application of criteria in the standard.

· To provide an understanding of accept/reject criteria to enhance an individual’s motivation and ability to consistently and correctly apply the technical discrimination criteria.

· To teach methods and processes to improve an individual’s skills and ability to achieve acceptable workmanship.

· To teach methods and techniques how to use, navigate, locate and to apply the criteria contained in a document to the appropriate class or classes of production.

To be accountable, reliable, and credible to our suppliers and also our customers, this is why ACDi values the adoption of IPC standards. Our customers can be assured we build only the highest quality products on their behalf, and that they can, in turn, reassure their own end users that products will perform.

What are the definition and content of IPC PCB?

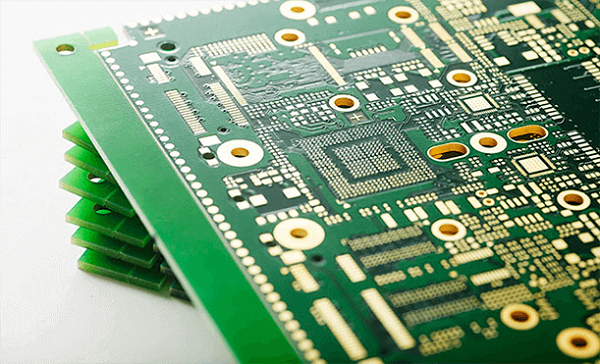

Since IPC creates standards for the electrical and electronics industry, it also plays a crucial role in producing standards for PCBs. You can find IPC standards for PCB manufacturing at every stage of the PCB production process, including design and manufacturing.

IPC PCB standards also set requirements for soldering electrical and electronic work in PCBs. These soldering standards often relate to reflow and wave soldering, as well as solder splices. Companies also rely on them to see if their electrical and electronic assemblies are acceptable during manufacturing. IPC standards also cover cable and wire harness assemblies. Finally, they set acceptability standards for the manufacture, inspection and testing of electronic enclosures before the PCB is released as a final product.

Industry Category