By:PCBBUY

03/16/2023 14:49

Printed Circuit Boards (PCBs) are the foundational components that enable electrical connectivity in nearly all modern electronic devices. Their versatility—from simple single-layer designs to complex high-density, flexible, or high-frequency variants—makes them indispensable across countless industries. Where are printed circuit boards used? Here's a detailed breakdown of the key electronic devices and categories that rely on PCBs.

PCB Instant Quote

If you are curious about the information about electronic devices in PCB, please check and read the content below in this passage.

What are the common uses of electronic devices in PCB?

Consumer electronics are the most common users of PCBs, as they require compact, reliable, and cost-effective circuit integration.

Smartphones & Mobile Devices:

Use High-Density Interconnect (HDI) PCBs with 6–12+ layers, fine traces, and microvias to pack processors memory, cameras, 5G modems, and sensors into a small space. Flexible PCBs (FPCBs) also connect foldable screens or internal components.

Computing Devices:

Laptops/Desktops: Motherboards (4–16 layers) connect CPUs, RAM, GPUs, and storage; graphics cards use PCBs with high-current traces for power-hungry GPUs.

Tablets/E-readers: Slim multi-layer PCBs integrate touchscreens, processors, and batteries.

Peripherals: Keyboards, mice, printers, and external drives use simple single/double-layer PCBs for basic functionality.

Home Appliances:

Kitchen: Microwaves (control timers/sensors), coffee makers (programmable settings), and air fryers (temperature regulation).

Climate Control: Smart thermostats, air conditioners, and heaters (PCB-based controllers for sensors and displays).

Entertainment: TVs (PCBs for HDMI, display drivers, and audio processing), gaming consoles (e.g., PS5, Xbox), speakers, and soundbars.

PCBs are critical for enabling wired and wireless communication by supporting signal processing, amplification, and connectivity.

Networking Equipment:

Routers, modems, Wi-Fi 6/7 access points, and Ethernet switches use PCBs with impedance-controlled traces and RF (radio frequency) components to handle high-speed data transmission with minimal loss.

Telecom Infrastructure:

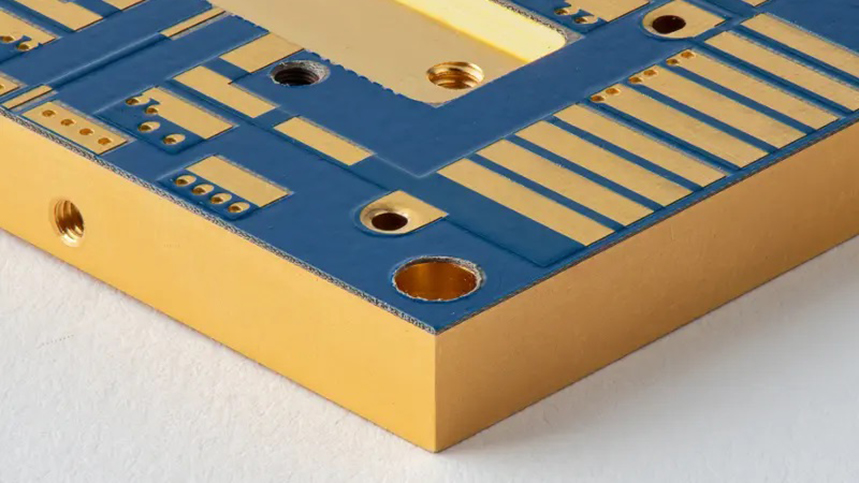

5G/4G base stations, fiber optic transceivers, and satellite modems rely on high-frequency PCBs (using materials like Rogers) to manage GHz-range signals, critical for long-distance communication.

Wearables & Portable Communicators:

Smartwatches, fitness trackers, and Bluetooth headsets use flexible PCBs (FPCBs) or rigid-flex PCBs to fit curved designs, connecting heart rate sensors, batteries, and wireless modules.

Modern vehicles depend on PCBs for safety, efficiency, and connectivity, with designs ruggedized to withstand temperature extremes, vibration, and moisture.

Safety Systems:

Airbag control units, anti-lock braking systems (ABS), and collision sensors use PCBs to process real-time data from sensors and trigger responses.

Infotainment & Navigation:

Touchscreen displays, GPS systems, and car stereos use PCBs for audio/video processing, Bluetooth/USB connectivity, and user interface controls.

Electric/Hybrid Vehicles (EVs/PHEVs):

Battery Management Systems (BMS): PCBs monitor and balance battery cells to prevent overcharging.

Motor Control Units: High-current PCBs regulate power flow to electric motors, ensuring efficient performance.

These sectors require PCBs with high reliability, precision, and compliance with strict standards (e.g., ISO, IPC).

Industrial Equipment:

Automation: Programmable Logic Controllers (PLCs), robotics, and manufacturing sensors use PCBs to control machinery and transmit data.

Monitoring: Industrial sensors (temperature, pressure) and power supplies rely on ruggedized PCBs for factory environments.

Medical Devices:

Diagnostics: MRI machines, X-ray systems, and blood pressure monitors use PCBs to process sensor data and generate results.

Therapeutics: Pacemakers, insulin pumps, and defibrillators use small, biocompatible PCBs (often FPCBs) for long-term, precise operation.

Monitors: EEG/ECG machines and pulse oximeters depend on PCBs for real-time data processing.

PCBs here must endure extreme conditions (radiation, vibration, temperature swings) and meet strict reliability standards.

Aerospace:

Aircraft avionics (navigation, radar, communication radios) use lightweight, radiation-hardened PCBs. Satellites and drones rely on PCBs for long-term space/mission durability.

Defense:

Missile guidance systems, military radar, and secure communication radios use ruggedized PCBs with EMI (Electromagnetic Interference) shielding to prevent signal disruption in high-noise environments.

IoT devices use compact, low-power PCBs to enable connectivity and data exchange.

Examples:

Smart home: Security cameras, smart bulbs, and doorbells.

Environmental: Weather stations, air quality monitors, and agricultural sensors.

Asset tracking: GPS-enabled devices for logistics and fleet management.

Single/Double-Layer PCBs: Toys, calculators, basic sensors.

Multi-Layer PCBs: Smartphones, computers, automotive systems.

Flexible PCBs (FPCBs): Wearables, foldable phones, curved displays.

Rigid-Flex PCBs: Aerospace and medical devices needing both rigidity and flexibility.

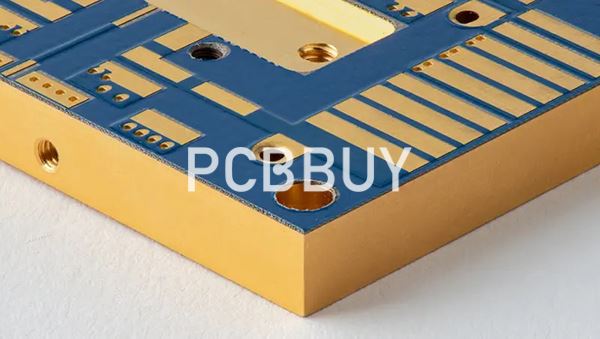

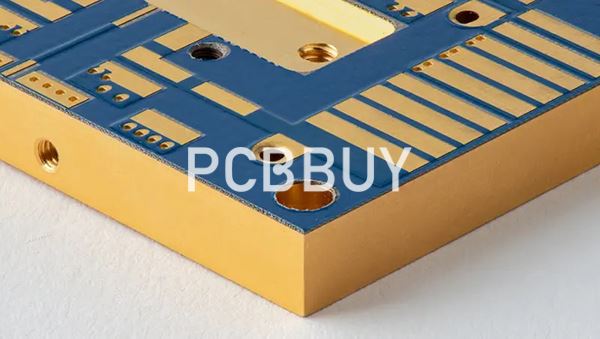

High-Frequency PCBs: 5G, Wi-Fi, and satellite communication devices.

In short, PCBs are the "invisible backbone" of electronics, enabling functionality in everything from pocket-sized gadgets to industrial machinery and space-bound equipment. Their design is tailored to each device’s unique needs, ensuring performance, reliability, and efficiency.