What Is A Toaster Pcb?

By: 09/12/2023 13:51

A toaster is a household appliance used for making bread, and its function is to place the dough inside the machine and produce various shapes and flavors of bread through the baking process. PCB, as one of the key components in the toaster, plays important roles in electronic control, heat control, and safety protection. Therefore, research on the toaster's PCB is of great significance.

what is toaster?

A toaster is a household appliance used for making bread. It typically consists of several components, including the outer casing, heating elements, heat conductors, control components, and a bread tray.

The PCB of a toaster is the foundation of the toaster's electronic control system, connecting and controlling all electronic components such as resistors, capacitors, transistors, IC chips, etc. Therefore, designing a high-performance and reliable PCB is crucial for manufacturing high-quality toasters.

The outer casing is the outermost structure of the toaster, usually made of metal or plastic, providing strength and heat resistance. Heating elements are one of the main working parts of the toaster, typically composed of electric wires or tubular heaters. When powered, they generate heat, which is transferred to the bread tray through heat conductors. Heat conductors are usually made of metal plates or heat-conductive materials attached to the heating elements, ensuring even heat distribution onto the bread tray. Control components serve as the central control unit of the toaster, consisting of temperature sensors and control circuit boards. They regulate the temperature and time of the heating elements to control the degree of toasting. The bread tray is the part of the toaster where the bread is placed. It is typically made of metal or plastic and has adequate heat resistance and load-bearing capacity.

The working principle of a toaster involves the heating elements generating heat, which is then transferred to the bread tray through the heat conductors. This process heats and toasts the bread. During toasting, the control components can adjust the temperature and time of the heating elements to control the degree of toasting. Generally, toasters have preheating and automatic shutdown functions, ensuring safe and reliable operation during toasting.

Toasters have a wide range of applications in daily life. People use toasters to conveniently and quickly make various types and flavors of bread, such as sliced bread, French bread, whole wheat bread, and more. Using a toaster allows for the efficient preparation of bread while saving time and effort. Therefore, toasters have become an indispensable kitchen appliance in modern households.

what is toaster used for?

The primary purpose of a toaster is to toast bread slices, and it typically consists of a multifunctional toaster oven, heat-insulated toaster slots, and a special lifting mechanism. In addition to making toast, a toaster has various other uses:

Commercial Use: In commercial settings such as restaurants, cafes, hotels, and more, a toaster can be used to prepare various baked goods like toast, croissants, muffins, and cornbread, diversifying the menu to attract customers. Moreover, a toaster can enhance operational efficiency, reduce labor costs, and increase profits.

Travel Use: Travelers can use a toaster to create portable baking equipment, allowing them to enjoy delicious bread while on the go. Toasters can adapt to different voltages and plug types, facilitating international travel.

Gifts: Toasters can serve as practical and fun gifts, given to family and friends to express care and blessings. Furthermore, toasters come in a variety of colors and styles to cater to different people's aesthetics and preferences.

In summary, a toaster is a highly practical kitchen appliance that can quickly and conveniently prepare toast, improving the toasting effect and texture. It also has various uses, making it suitable for different scenarios and needs.

Design Principles

(1) Layout

In the PCB design of a toaster, layout is a crucial step. A well-designed layout can improve circuit reliability and reduce the occurrence of faults. Layout considerations include the distance, orientation, and arrangement sequence of components, as well as factors like heat dissipation and electromagnetic shielding.

(2) Layer Count

The layer count of a toaster's PCB depends on the complexity of the circuit and space limitations. For simple toaster circuits, single-sided or double-sided boards may be used, while complex circuits require multilayer boards. Multilayer boards provide more routing space and better EMC performance.

(3) Impedance and Crosstalk

Impedance and crosstalk are important factors affecting PCB performance. Impedance mismatch can lead to signal reflection and distortion, while crosstalk can result in signal interference and noise. Therefore, impedance matching and crosstalk suppression should be considered when designing a toaster's PCB.

Manufacturing of Toaster PCBs

Manufacturing Process

The manufacturing process of a toaster's PCB includes the following main steps:

(1) Preprocessing: This involves cleaning, drying, and coating the board material.

(2) Circuit Printing: Printing the circuit pattern onto the board material.

(3) Exposure and Development: Using ultraviolet light to transfer the circuit pattern onto the board material.

(4) Etching: Removing the unexposed parts to form the actual circuit pattern.

(5) Copper Plating: Coating the circuit pattern with a conductive copper layer.

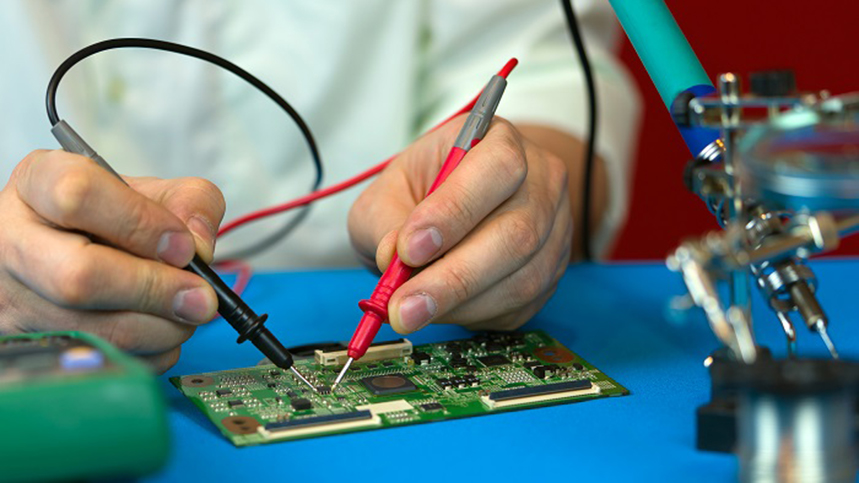

(6) Soldering: Connecting electronic components to the PCB.

Issues and Solutions During Manufacturing

(1) Open Circuits and Short Circuits

Open circuits and short circuits are common issues during PCB manufacturing. Open circuits are mainly caused by factors such as fine printed lines, poor connections, or incomplete etching, while short circuits are primarily due to uneven coating, overexposure, or over-etching. To address these problems, strict control of various parameters during the manufacturing process and effective quality testing are necessary.

(2) Warping and Cracking

Warping and cracking are common issues during PCB manufacturing and use. Warping is mainly caused by board deformation, while cracking results from the release of internal stress in the board material. To address these issues, it's important to control board material temperature, humidity, tension, and adopt special design and manufacturing processes."

Please note that this translation provides a general overview of the text. PCB manufacturing involves technical details that may require specialized terminology and context-specific knowledge.

Industry Category