What Is Automated Assembly in PCB Manufacturing with 5 Aspects?

By:PCBBUY 04/02/2022 10:19

It's almost impossible for current electronic devices to work without a circuit board. A PCB plays a critical role in electrical connection between components such as integrated circuits (ICs) that are assembled on bare boards applied in different electronic devices ranging from relatively simple equipment such as electronic watches, calculators, handheld computers, electronic communication equipment to advanced electronic devices like military, medical or aerospace products.

In this passage, we are going to tell you all about automated assembly in PCB manufacturing. If you are going to learn more about automated assembly in PCB manufacturing, please check and read the content below.

What are the advantages of automated assembly in PCB?

Lower Overall Cost

Using automated PCB assembly means that you can expect lower overall costs. Many SMT assemblers use exclusive software to assemble the circuit board digitally before actual production. This is to reduce the risk of errors and delays. During this process, PCB designers can fix any design errors which then removes possible issues when production begins. Errors such as omitted polarity marks and incorrect footprints can cause project delays. The use of automated assembly also means that fewer employees are needed for the task. This can lead to financial savings for the assembler which means that the cost of production of PCBs can be lower.

Reduces Human Error

The process of printed circuit board assembly is a delicate task and can often be very difficult. The assembly of circuit boards requires great attention to detail. With circuit boards and components getting smaller, all of the parts must be soldered correctly in order to avoid errors. Whilst mistakes can be made, machines that are designed for repetitive and delicate tasks are less likely to make mistakes when compared to an employee. In these situations, automated machines are more capable of getting more done, in less time, whilst remaining accurate. Ultimately, machines that are deployed in situations where extreme accuracy is needed, can reduce the margin of error.

Shortened Product Development Cycle

The time invested into hand-assembly can vary depending on the circuit board which produces inconsistent time frames for completion. Hand-assembled PCBs can take longer to develop which may be counter-productive if you have several other operations that you could be completed at the same time. By using an automated PCB assembly service, you can be assured that your boards will be delivered in high-quality conditions, whilst enabling you to complete multiple steps in parallel. Therefore, saving you time and money.

Consistent Quality

As an automated machine is designed and programmed to perform the same task repetitively, the accuracy and quality of circuit boards can be better and more consistent than hand-assembly. Automation allows you to preserve the likeliness for each board produced so you can expect consistent quality when you partner with an assembly service.

What is the process of automated assembly in PCB?

Many of our valued customers contact us to learn the exact process Bittele follows for board assembly. Bittele’s qualified engineers follow defined steps in the PCB assembly process. Our PCB assembly process include preparing the circuit board’s surface, placing the parts, soldering, cleaning and inspection & testing. Our trained assembly technicians diligently follow defined procedures and use modern methods of component placement for circuit board assembly.

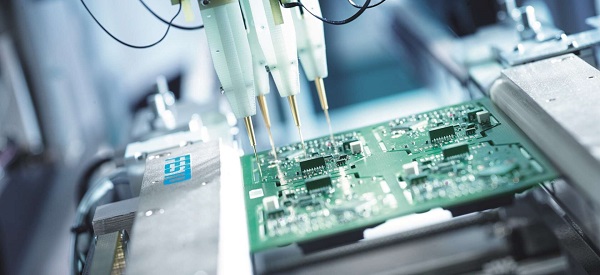

We use both automated and manual techniques for placing PCB components. Generally, through-hole parts are placed manually whereas surface-mount components are placed with the use of a pick and place machine. Most of the time, automated assembly is not feasible for a small number of PCBs.

The soldering methods used by our team are wave-soldering for through-hole components and reflow soldering for surface-mount components. In the through-hole assembly process, the parts are placed on the PCB and wave-soldering is used to solder the leads for through-hole components. In the SMT assembly process, solder paste is applied via solder stencil on the PCB, then parts are placed on pads, and processed in a reflow oven to melt the solder paste. Furthermore, in mixed technology PCBs are both wave-soldered and reflowed.

After the circuit board is soldered, it is cleaned by our team. We use the latest techniques to clean the assembled circuit boards in order to remove all flux residue. Furthermore, different techniques are used to remove flux residue, which is generally a combination of cleaning agents, agitation, and heat. Then, the circuit board is sent for detailed inspection to check for accurate component placement.

State-of-the-art inspection tools are used to check the quality of the assembled boards. Some of the techniques used include sample checks, automated optical inspection (AOI), X-ray inspection, etc. After a thorough quality testing, the boards are delivered to the end customers.

Industry Category