What Is Egg Boiler Pcb?

By:PCBBUY 09/13/2023 11:07

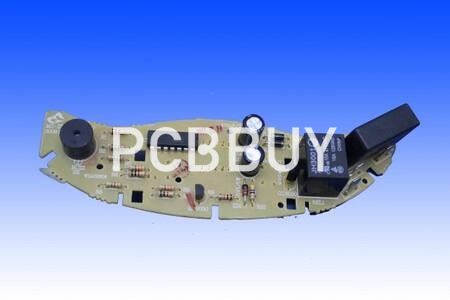

The egg boiler circuit board is an essential electronic component used to control various functions of the egg boiler. It primarily consists of electronic elements and integrated circuits, capable of regulating heating temperature and duration according to pre-set programs. This ensures the safe, stable, and reliable operation of the egg boiler. This paper will delve into the design, manufacturing, testing, and other aspects of the egg boiler circuit board, with the aim of enhancing its quality and performance, thus laying a solid foundation for the overall functionality of the egg boiler.

what is an egg boiler?

An egg boiler is a device used for quickly and conveniently cooking chicken eggs, and it can also be used to prepare egg custard. It utilizes a heating plate that is powered to generate high-temperature steam within the plate to rapidly cook the eggs.

what is an egg boiler PCB?

An egg boiler PCB (Printed Circuit Board) is an essential electronic component used in egg boilers or egg cookers. It plays a crucial role in controlling the various functions and features of the appliance, ensuring that eggs are boiled or cooked precisely according to the user's preferences. In this article, we will explore the functions, components, and design considerations of an egg boiler PCB in detail.

Introduction to Egg Boilers:

Egg boilers, also known as egg cookers or egg steamers, are kitchen appliances designed to simplify the process of cooking eggs. These devices are popular for their convenience and ability to prepare eggs quickly and with consistent results. They are particularly useful for those who enjoy hard-boiled, soft-boiled, or poached eggs.

The Role of PCB in Egg Boilers:

The PCB in an egg boiler serves as the brain of the appliance, controlling and managing various functions to ensure that eggs are cooked to the desired level of doneness. Here are some key functions that the PCB facilitates:

Temperature Control: The PCB monitors and controls the heating element's temperature to maintain the water or steam at the optimal level for egg cooking. Different temperatures are required for soft-boiled, medium-boiled, and hard-boiled eggs.

Timer Function: The PCB includes a timer feature that allows users to set the cooking duration. When the timer reaches the specified time, the appliance automatically switches off or signals the end of the cooking cycle.

Safety Features: Many egg boilers incorporate safety features like overheat protection and auto-shutoff to prevent accidents or damage to the appliance in case of malfunction.

Cooking Modes: Some egg boilers offer multiple cooking modes, such as poaching or steaming, in addition to boiling. The PCB controls the selection of these modes and adjusts the cooking process accordingly.

Components of an Egg Boiler PCB:

A typical egg boiler PCB consists of various components that work together to achieve precise and safe egg cooking. These components include:

Microcontroller or Microprocessor: The heart of the PCB is a microcontroller or microprocessor unit responsible for executing programmed instructions and managing the cooking process.

Temperature Sensor: To monitor the water or steam temperature accurately, a temperature sensor, such as a thermistor or thermocouple, is integrated into the PCB.

Timer Circuit: The timer circuit controls the duration of the cooking cycle. It can be a simple timer IC or a more advanced programmable timer.

Display: Some egg boilers feature an LED or LCD display to show the cooking time, selected mode, and other information. The PCB controls the display output.

Control Buttons: User interface buttons or switches are connected to the PCB, allowing users to set preferences, start the cooking process, and select cooking modes.

Relays and Switches: Relays are used to control the heating element's power supply and other electrical components. The PCB activates these relays based on user settings and temperature readings.

Safety Components: To ensure safety, the PCB may include components like thermal fuses or cutoff switches that can disconnect power in case of overheating or malfunction.

Design Considerations for Egg Boiler PCBs:

When designing a PCB for an egg boiler, several factors must be considered to ensure optimal performance and safety:

Power Supply: The PCB should support the power requirements of the heating element and other components. Voltage regulation and protection circuits may be necessary.

User Interface: The user interface should be intuitive, with clear buttons and an informative display.

Temperature Control: Precise temperature control is essential for cooking eggs correctly. The PCB must incorporate an accurate temperature sensor and a reliable control algorithm.

Safety: Safety features like overheat protection and automatic shutoff should be incorporated to prevent accidents or damage.

Reliability: Components should be selected for their reliability and durability, as egg boilers are often used frequently.

Testing and Quality Control: Rigorous testing of the PCB and the entire egg boiler is essential to ensure consistent performance and safety.

Selection of Electronic Components

The selection of electronic components is a crucial factor in the design of an egg boiler PCB. When choosing electronic components, the following factors need to be considered:

Specifications and Parameters of Electronic Components: The specifications and parameters of electronic components serve as the foundation for circuit design. It's essential to select components based on parameters such as temperature tolerance, voltage ratings, current handling capacity, and voltage requirements to ensure that the components meet the needs of the circuit.

Reliability and Stability of Electronic Components: The reliability and stability of electronic components are vital for the overall performance of the circuit. High-quality and stable components should be chosen to ensure the PCB's stability and reliability.

Size and Mounting of Electronic Components: The size and mounting methods of electronic components also play a significant role in PCB design. Consideration should be given to the physical dimensions of the components and how they will be mounted on the PCB.

Design and Manufacturing of the Printed Circuit Board (PCB)

The PCB is the backbone of the egg boiler, and its design and quality significantly impact the performance and user experience. Several factors need to be taken into account when designing and manufacturing the PCB:

Selection of PCB Materials and Thickness: The choice of materials and thickness for the PCB is fundamental. Materials should be selected based on factors like mechanical strength, heat resistance, and insulating properties to ensure that the PCB meets the circuit's requirements.

Number of PCB Layers and Wiring Configuration: Decisions regarding the number of PCB layers and the wiring configuration are essential. The PCB should be designed according to the specific requirements of the circuit, taking into account considerations like signal integrity and impedance control.

PCB Manufacturing Process: The manufacturing process of the PCB is a critical factor. The chosen manufacturing process should be feasible, stable, and reliable to ensure the PCB's quality and performance meet the requirements.

Selection of Soldering Techniques

Choosing the appropriate soldering techniques is a crucial aspect of manufacturing the egg boiler PCB. Several considerations need to be made in this regard:

Choice of Soldering Materials: Selecting the right soldering materials is fundamental. Factors such as material composition, mechanical strength, and resistance to corrosion should be considered to ensure that the soldering materials meet the requirements.

Control of Soldering Temperature and Time: Controlling soldering temperature and time is a key technical aspect of the soldering process. Proper control of these parameters is essential to ensure the quality and performance of the solder joints meet the requirements.

Selection of Soldering Equipment and Tools: The choice of soldering equipment and tools is another critical consideration. Factors such as equipment reliability, stability, and automation levels should be taken into account to ensure that the soldering process meets quality and efficiency standards.

In conclusion, an egg boiler PCB is a crucial component in egg boiler appliances, managing temperature control, timers, user interfaces, and safety features. Designing a reliable and efficient egg boiler PCB requires careful consideration of various components and functions to provide users with perfectly cooked eggs while prioritizing safety and convenience.

To create an egg boiler circuit board online, please click here.

Industry Category