What Is Electronic Component Lifecycle Management in PCB Manufacturing?

By:PCBBUY 03/22/2022 09:44

Product lifecycle management: it’s one of those business processes that is thrown around by industry types, but designers may not understand how it affects product design and product development for new electronics and the circuit boards that support them. Managing product design, development, manufacturing, and distribution are just one aspect of taking a new product to market.

If you are searching for more professional knowledge of electronic component lifecycle management in PCB, please check and read the content below in this passage.

What is component sourcing data in product lifecycle management software?

Some common problems in the life cycle management process arise due to a lack of sourcing information throughout the design process, lack of access to component model updates and obsolescence information, and a scattered documentation repository. Problems that fall into these three categories can seriously hamper the design process for circuit boards, as well as planning for manufacturing and sourcing. Keeping documentation in a consistent format with a consistent file structure allows design teams to easily track product updates and new capabilities as products are continuously innovated and modernized.

Obsolescence management is a very important part of developing and manufacturing any new piece of technology. Your new product should compete with other products on every level as soon as it hits the market, meaning you need to include the most up-to-date components in your circuit boards. Having real-time access to supply chain information helps you identify which components in your design will become obsolete before you release your design to the market.

The product lifecycle management process for printed circuits mimics that seen in other industries. Keeping meticulous documentation and organizing design data are the best ways to be responsive throughout the product life cycle.

ECAD tools play an important role in life cycle management for printed circuit boards and electronic products. Your sourcing data should appear in your BOM and should be pulled directly from your component libraries.

When your design features are built for data exchange in a single environment, your design and data management business processes become seamless and your data is easily passed between your design and documentation tools.

What is component lifecycle impact on PCB manufacturing?

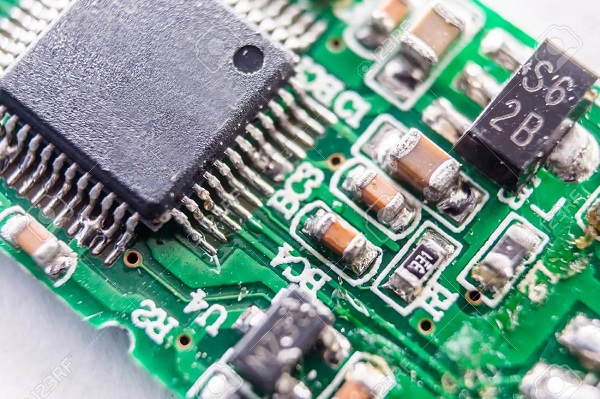

Although typically not expressed as such, PCB development is also characterized by variance in the number of boards required at different stages. For prototyping, the number of boards may range from a few to hundreds depending on how close the design is to finalization. For production, PCBs have life cycles similar to other manufactured products. In fact, PCB life cycles typically mirror the life cycles of the electronic devices in which they are deployed.

More component availability is undoubtedly necessary for production; however, component selection occurs during design, which precedes prototyping. Therefore, selecting components such that adequate numbers are available throughout PCB development and production is an essential aspect of project management. The best, or less risky, way to ensure adequate supply is through component warehousing or advance procurement of the estimated number of components to sustain production for a substantial time period.

This period should be long enough to facilitate the selection of substitute components and testing and verification (if necessary) of a new design without interruptions to the production cadence. The drawback here is the upfront cost, which may be quite significant depending upon your design complexity and number of components.

As it may be cost-prohibitive or otherwise impractical to warehouse projected components for development and production, an alternative strategy for guarding against component shortages that takes the component lifecycle into account is warranted. The table below lists the stages of the component lifecycle where components can be safely selected for PCB prototyping or production.

How to managing the lifecycle of PCB components?

Component engineers daily handle requests from their own purchase teams as well as from the customers that they serve. Everything from production runs to prototypes and new product introductions will come to them for help in choosing the best components for the board. To do their job, component engineers will use online tools that help them monitor part availability, changes, compliance, shelf-life, and production lifecycles. These tools plug into component databases that contain millions of parts from thousands of manufacturers and will alert its users when product change notices (PCNs) are posted.

With the part information from these databases, the component engineers have access to all of the device specifications in order to identify equivalent and alternate components. At the same time, the component engineer will also monitor the PCNs that are directly sent by part distributors. This gives them a head start on knowing what changes may be coming to the parts they are using before the component databases in the online tools are updated.

Industry Category