What Is PCB Board Thickness: Principles Impacts and Comparative Analysis?

By:PCBBUY 09/26/2024 14:45

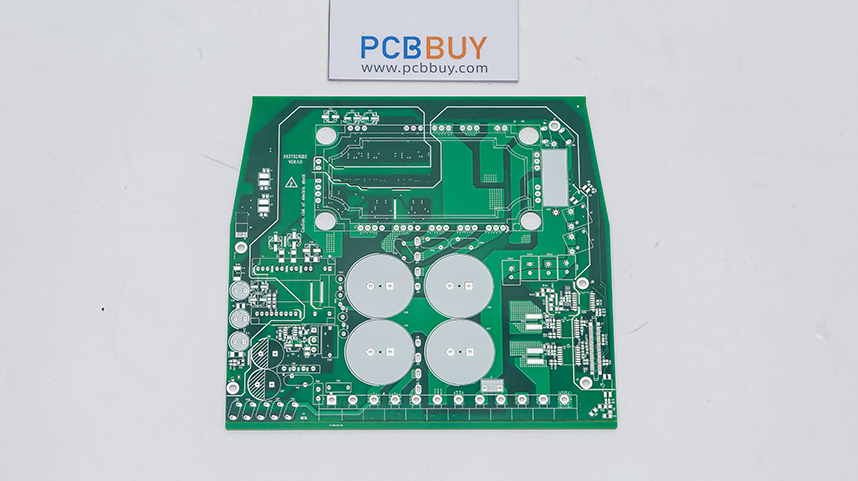

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing the essential infrastructure for connecting electronic components. One critical parameter in PCB design is board thickness, which significantly influences the performance, reliability, and manufacturability of electronic devices. This article explores the principles behind PCB board thickness, its implications on various performance metrics, and a detailed comparison of standard thicknesses used in the industry.

1. What is PCB Thickness?

PCB thickness refers to the overall thickness of the circuit board, including all layers such as substrate, copper traces, and solder mask. The thickness is usually measured in mils (1 mil = 0.001 inches) or millimeters (mm), with standard thicknesses typically ranging from 0.2 mm to 3.2 mm.

1.1 Standard PCB Thicknesses

The following table outlines the most common PCB thicknesses used in the industry:

|

Thickness (mm) |

Thickness (mils) |

Application |

|

0.2 |

8 |

Flexible PCBs |

|

0.4 |

16 |

General Applications |

|

0.6 |

24 |

High-Density Designs |

|

1.0 |

40 |

Standard PCBs |

|

1.6 |

62 |

Most Common |

|

2.0 |

79 |

Heavy-Duty Designs |

|

3.2 |

125 |

Industrial Applications |

2. Principles of PCB Thickness

2.1 Material Properties

The materials used in PCBs, primarily FR-4 (a composite of fiberglass and epoxy), have inherent properties that are influenced by board thickness. The dielectric constant, thermal conductivity, and mechanical strength of the PCB materials all play a role in determining the appropriate thickness.

2.1.1 Dielectric Constant

The dielectric constant (Dk) is crucial for signal integrity, especially in high-frequency applications. A thicker PCB can increase the capacitance between layers, which may lead to impedance mismatches.

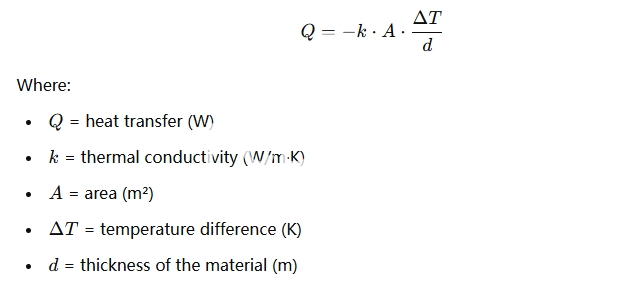

2.1.2 Thermal Conductivity

Thicker boards may have better thermal conductivity due to the increased volume of material, which can enhance heat dissipation in high-power applications. The relationship can be described by Fourier's Law of Heat Conduction:

2.2 Mechanical Strength

Thicker PCBs generally exhibit improved mechanical strength, reducing the risk of bending or breaking during handling and assembly. This is particularly important in applications subjected to physical stress or vibration.

3. Impacts of PCB Thickness

3.1 Signal Integrity

The thickness of a PCB can significantly impact signal integrity, particularly in high-speed applications. Thicker boards may lead to increased capacitance, which can distort high-frequency signals.

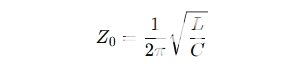

3.1.1 Impedance Control

Impedance is crucial for high-speed signal transmission. The impedance of a microstrip line can be approximated by the formula:

Where L is inductance per unit length and C is capacitance per unit length. A change in thickness alters the capacitance, affecting the impedance.

3.2 Thermal Performance

In high-power applications, such as power electronics, thicker PCBs can improve thermal performance by providing a larger heat dissipation area. This helps prevent overheating and enhances the reliability of the components.

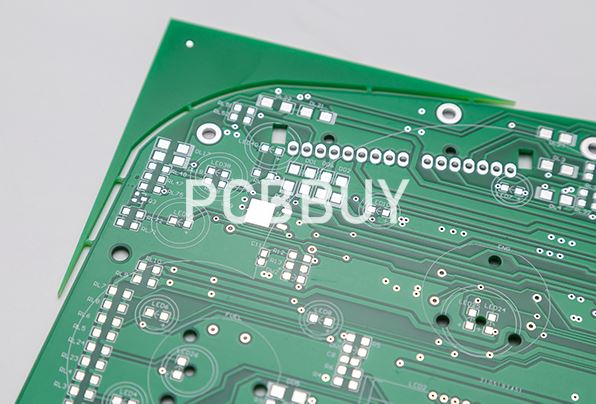

3.3 Manufacturing Considerations

Thicker PCBs can complicate manufacturing processes, including drilling and plating. Manufacturers must adjust equipment settings to accommodate varying thicknesses, which can lead to increased production costs and time.

4. Comparative Analysis of PCB Thickness

4.1 Common Thicknesses and Their Applications

The following table summarizes the common PCB thicknesses, their mechanical properties, and typical applications:

|

Thickness (mm) |

Flexibility |

Mechanical Strength |

Typical Applications |

|

0.2 |

High |

Low |

Flexible PCBs for wearables |

|

0.4 |

Moderate |

Moderate |

General consumer electronics |

|

0.6 |

Moderate |

Moderate |

High-density interconnects |

|

1.0 |

Low |

High |

Standard consumer products |

|

1.6 |

Low |

High |

Most electronic devices |

|

2.0 |

Low |

Very High |

Heavy machinery and industrial |

|

3.2 |

Very Low |

Very High |

Military and aerospace applications |

4.2 Performance Trade-offs

Choosing the appropriate thickness involves balancing performance characteristics:

Thicker Boards: Better thermal management and mechanical strength but can lead to signal integrity issues and higher manufacturing costs.

Thinner Boards: Improved flexibility and reduced material costs but may compromise mechanical strength and thermal performance.

Conclusion

Understanding PCB board thickness is crucial for designers and engineers working in the electronics industry. It impacts signal integrity, thermal performance, and mechanical strength, all of which are essential for reliable electronic devices. Selecting the right thickness requires careful consideration of the specific application and desired performance characteristics.

References

1. Hsu, J. (2017). "The Impact of PCB Thickness on Signal Integrity." Journal of Electronics Engineering.

2. Katz, R. (2019). "Thermal Management in Printed Circuit Boards." Journal of Thermal Science and Engineering Applications.

3. Nicolet, C., & Kalluri, S. (2020). "PCB Material Selection: The Role of Thickness." International Journal of Electronics and Electrical Engineering.

4. Wang, T., & Hu, Y. (2021). "Mechanical Properties of PCB Materials." Materials Science and Engineering Journal

5. Sharma, R. (2022). "Advances in PCB Manufacturing Technologies." Journal of Manufacturing Processes

Industry Category